Serialization system for small-scale pharmaceutical production

Ensure precise serialization and inspection of small production batches with a compact system that manages serialization data, verifies print accuracy, and facilitates manual product handling, streamlining packaging operations while minimizing errors.

Serializes and Verifies Packaging for Pharmaceuticals

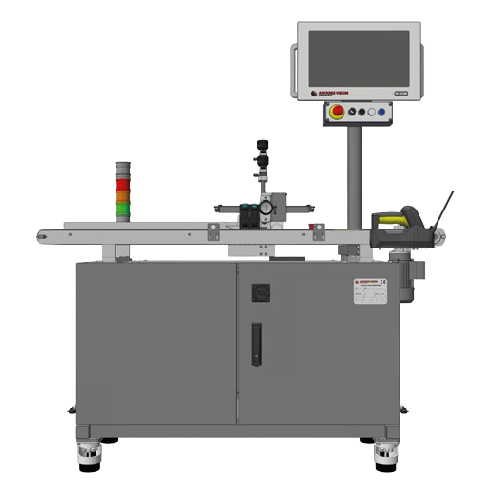

The Print & Check Small Production (VM3800) from Antares Vision Group is an ideal semi-automatic solution for pharmaceutical manufacturers and life sciences companies needing precision in serialization and verification of packaging. This standalone system expertly handles marking, recording, and verifying serialization data on medicine cartons and cosmetic product boxes. The VM3800 operates with a precise conveyor belt system, stopping when nonconformity is detected, allowing manual removal of erroneous packages. It also supports unformed and flat carton processing through manual readers and PTS software to facilitate aggregation functions. Operating at a speed of up to 60 pieces per minute, it accommodates various carton sizes with its flexible design. Equipped with an 18.5” ergonomic touchscreen and standard options like TIJ 2.5 printing and 1D/2D code inspection, it ensures high-grade print quality and track and trace capability. The system integrates seamlessly into existing production lines, supporting up to two printing heads and optional reject systems, enhancing overall operational efficiency while maintaining compliance with industry standards.

Benefits

- Enhances production accuracy with real-time serialization data verification.

- Minimizes error-related downtime through immediate nonconformity detection and pause.

- Streamlines packaging operations with flexible integration into existing lines.

- Supports diverse packaging needs with adjustable conveyor and carton size flexibility.

- Simplifies operator interface with an ergonomic 18.5” touchscreen.

- Applications

- Life sciences, Packaging solutions, Cosmetics, Pharmaceuticals

- End products

- Cosmetic product packaging, Serialized pharmaceutical boxes, Printed packaging labels, Medicine cartons, Skincare product boxes, Flat carton packaging for life sciences products

- Steps before

- Formulation, Carton Folding, Box Preparation

- Steps after

- Carton Sealing, Product Aggregation, Quality Inspection

- Input ingredients

- unformed boxes, cartons, serialization data

- Output ingredients

- serialized cartons, verified printed data, nonconforming boxes removed

- Market info

- Antares Vision is renowned for providing inspection, track and trace, and quality control systems primarily to the pharmaceutical, food, and beverage industries, ensuring product integrity and supply chain transparency.

- Line Speed

- Up to 60 Pcs/min (20 m/min)

- Conveyor Length

- 1500 mm

- Working Height

- 900 mm

- Printing Heads

- Up to 2 TIJ Printing Heads

- Printable Sides

- Up to 1

- Printing System

- TIJ 2.5 including print controller

- Max Resolution

- 600 dpi

- Datamatrix Print Quality

- Grade B typical, up to Grade A on selected backings

- Number of Cameras for Inspection

- Up to 1

- Carton Size

- A = 30-350 mm / B = 15-140 mm / C = 45-300 mm

- Flat Carton Size

- A = 45-350 mm / C = 90-300 mm

- Side of Print

- Machine or Top side

- Operator side available on request

- Automation level

- Semi-automatic

- Batch vs. continuous operation

- Batch

- Conveyor belt speed

- Up to 20 m/min

- Line speed

- Up to 60 Pcs/min

- Manual operation

- Manual reader for aggregation

- Nonconformity handling

- Belt stops for manual removal

- Item processing

- Serialization of unformed boxes

- Control interface

- 18.5” ergonomic touch screen

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Carton processing type

- Folded or flat

- Carton size range (assembled)

- A = 30-350 mm / B = 15-140 mm / C = 45-300 mm

- Carton size range (flat)

- A = 45-350 mm / C = 90-300 mm

- Printable sides

- 1 side (machine or top side

- Operator side available on request)

- Supported printing technology

- TIJ 2.5

- ISO/IEC 15415-2

- Datamatrix print quality

- Machine footprint

- 1500 mm

- Conveyor length

- 1500 mm

- Working height

- 900 mm

- Control panel type

- 18.5” touch screen

- Carton size

- A = 30-350 mm, B = 15-140 mm, C = 45-300 mm

- Flat carton size

- A = 45-350 mm, C = 90-300 mm

- Compact footprint

- Standalone module

- Control panel type

- 18.5” touch screen

- Automation level

- Semi-automatic

- Integration capabilities

- PTS software for aggregation

- Printing head options

- Up to 2 TIJ printing heads

- Side of print

- Machine or top side

- Carton processing

- Folded or flat cartons

- Speed variation

- Available upon request

- Custom reject system

- Available on request