High-speed aerosol filling system for personal care products

Streamline your aerosol production with a multi-functional rotary system that ensures precise fills and high-speed operations, perfect for maintaining product consistency across a wide range of personal care and home care aerosols.

Fills and Packages Aerosol Products Efficiently

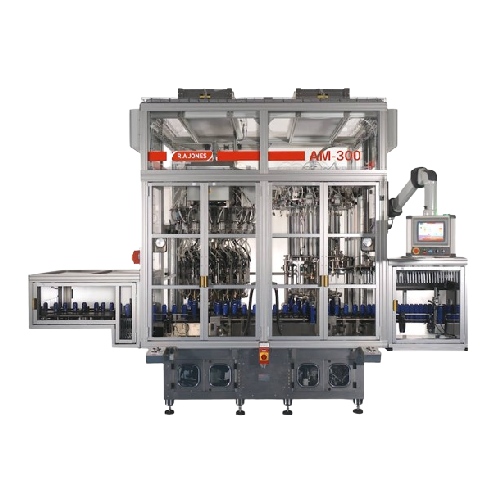

The KP-Aerofill AM-300 from R.A Jones is a multi-functional, high-speed rotary aerosol filling machine designed to optimize your production line with precision and efficiency. This mono-blocked system uses continuous operation to streamline the filling and packaging of diverse aerosol products like cooking sprays, deodorants, and insecticides. With a throughput of up to 300 containers per minute, it caters to the stringent requirements of the food, personal care, and home care industries.

The KP-Aerofill AM-300 integrates seamlessly into your existing production setup, featuring an automated, PLC-controlled system that allows for remote monitoring and minimal manual intervention. Engineered for durability and flexibility, it accommodates a range of packaging sizes and types, ensuring compliance with ATEX II 2G EExh safety standards. The robust design supports easy maintenance and cleaning, making it a reliable solution for high-volume aerosol manufacturing. Additionally, R.A Jones offers customization options to tailor the machine’s specifications to specific operational needs, providing engineering support throughout the process.

Benefits

- Enhances production efficiency with continuous high-speed operation up to 300 containers per minute.

- Reduces labor costs through automated, PLC-controlled integration and remote monitoring.

- Ensures safety and regulatory compliance with ATEX II 2G EExh standards.

- Adapts to various product types and packaging needs, maximizing line flexibility.

- Minimizes maintenance downtime with a design focused on ease of cleaning and servicing.

- Applications

- Hair care, Men's shaving, Fragrances, Deodorants, Fats, Air care, Oils, Home insecticides

- End products

- Aftershave aerosol, Shaving cream, Olive oil spray, Flea spray, Bug spray, Dry shampoo, Antiperspirant sprays, Body sprays, Cologne, Air freshener sprays, Hair mousse, Hairspray, Cooking spray

- Steps before

- Blending, Mixing, Formulation, Concentration Adjustment

- Steps after

- Can Sealing, Labeling, Packing, Quality Inspection

- Input ingredients

- oils, fats, deodorants, fragrances, men's shaving products, air care products, home insecticides, hair care products

- Output ingredients

- cans of oils, cans of fats, cans of deodorants, cans of fragrances, cans of men's shaving products, cans of air care products, cans of home insecticides, cans of hair care products

- Market info

- R.A Jones (Coesia Group) is known for its expertise in designing and manufacturing packaging equipment and automation solutions, specializing in cartoning, pouching, and high-speed filling, with a strong reputation for innovation and reliability in the industry.

- Operating mode

- Continuous

- Speed

- Up to 300 cpm

- Max pack diameter

- 66 mm

- Min pack diameter

- 35 mm

- Max pack height

- 265 mm

- Min pack height

- 70 mm

- Packaging type

- Cans

- Machine depth

- 1732 mm

- Machine height

- 3185 mm

- Machine length

- 4315 mm

- Machine weight

- 5000 kg

- Operating mode

- Continuous

- Batch vs. continuous operation

- Continuous

- Automation level

- High-speed rotary

- Packaging type

- Cans

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Packaging type

- Cans

- ATEX certification

- ATEX II 2G EExh

- Safety Regulations

- ATEX II 2G EExh

- Machine depth

- 1732 mm

- Machine height

- 3185 mm

- Machine length

- 4315 mm

- Machine weight

- 5000 kg

- Max pack diameter

- 66 mm

- Min pack diameter

- 35 mm

- Max pack height

- 265 mm

- Min pack height

- 70 mm

- Packaging type

- Cans

- Compact footprint

- Depth