Explosion-proof horizontal bead mill for fine grinding

Ensure precise, explosion-proof grinding in hazardous environments with this advanced bead mill, designed to handle challenging dispersion tasks while maintaining superior product quality and safety standards.

Mixes and Disperses High-Viscosity Materials

The DISPERMAT® SC4 dissolver from VMA-GETZMANN is designed to optimize your laboratory and pilot plant mixing processes. It excels in dispersing high-viscosity materials, making it indispensable for industries ranging from pharmaceuticals to automotive paints. Utilizing a high-energy rotational system, it ensures uniform mixing and particle reduction, even in challenging applications like lithium-ion battery electrodes or digital inkjet inks.

With a power capacity ranging from 15 to 22 kW, it manages product volumes from 30 to 600 liters efficiently. Its PLC-control enables seamless integration into existing production lines, offering automated mixing with remote monitoring capabilities. Engineered for energy efficiency, it reduces operational costs while maintaining precision, thanks to optimized motor control.

Constructed from durable materials, including options for ATEX-compliant environments, it provides excellent corrosion resistance. The unit supports both batch and continuous operations, ensuring versatility across processing needs. Easy maintenance is facilitated by a clean-in-place (CIP) system, and customization options are available for specific requirements, such as rotor speed adjustments and chamber configurations. Ideal for manufacturers and researchers seeking quality and reliability in their mixing processes.

Benefits

- Enhances product quality with precise and consistent dispersion in high-viscosity applications.

- Integrates seamlessly into production lines, reducing setup times with PLC-controlled operation.

- Lowers operational costs through energy-efficient motor optimization.

- Offers flexible handling of both batch and continuous processes, adapting to various production needs.

- Meets stringent environmental and safety standards, suitable for ATEX-compliant environments.

- Applications

- Spice pastes, Printing inks, Food additives, Agrochemicals, Carbon materials, Cosmetic products, Fuel cells, Ceramic products, Adhesives and sealants, Coating materials, Biotechnological applications, Automotive paints, Batteries, Pharmaceuticals

- End products

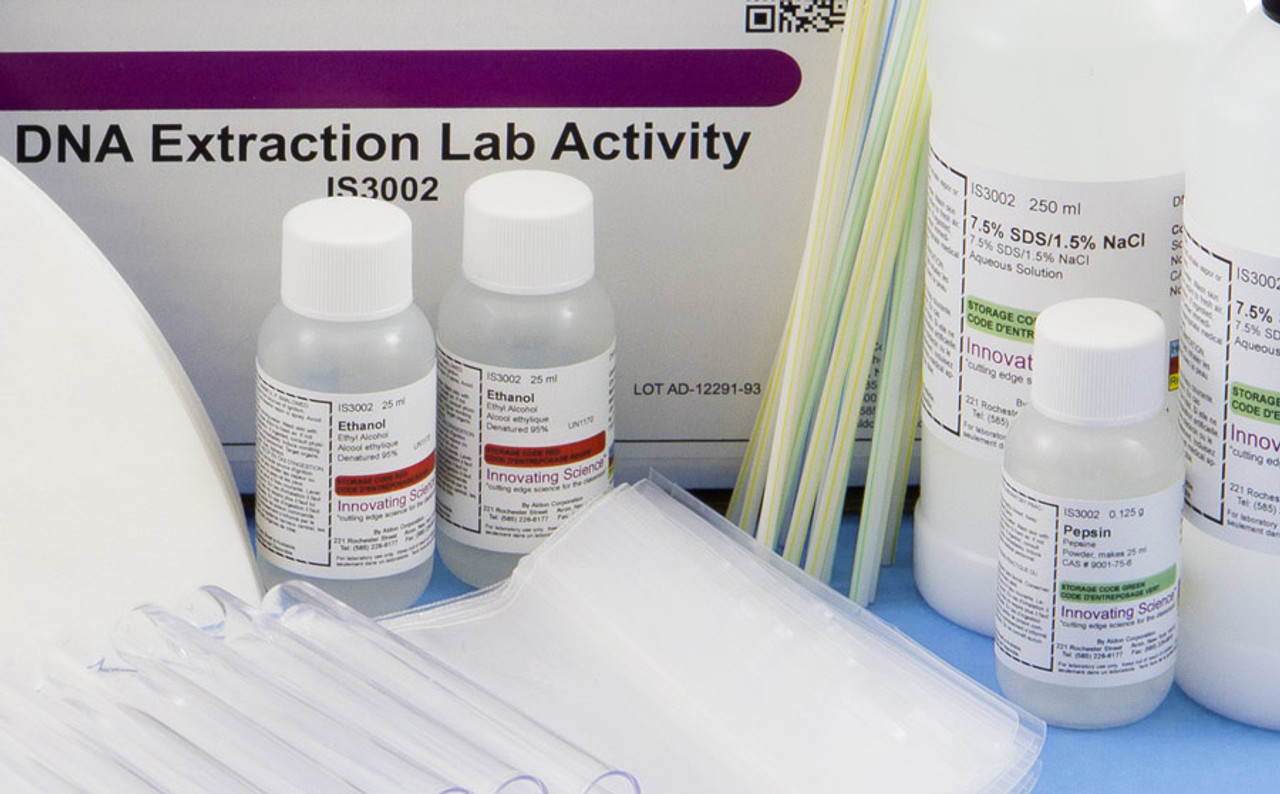

- Moisturizing creams, Dna extraction kits, Active pharmaceutical ingredients, Porcelain tiles, Structural adhesives, Solid oxide fuel cells, Lithium-ion battery electrodes, Anti-corrosion coatings, Natural food colorants, Digital inkjet inks, Automotive basecoats, Curry pastes, Herbicides, Carbon nanotubes

- Steps before

- Purification, Drying, Pre-mixing, Raw material preparation, Pre-dispersion

- Steps after

- Sterilization, Packing, Coating, Tablet Pressing, Quality control

- Input ingredients

- raw materials, ingredients, pigments, slurries, anode materials, cathode materials, conductive additives, binders, emulsion, latex, natural pigments, fats, oils, adhesives, sealants, silicones

- Output ingredients

- homogeneous mixtures, dispersed products, coatings, paints, inks, glazes, pastas, polishing agents, composite materials, battery compounds, packages, ceramic coatings, varnishes, cosmetic products, food supplements

- Market info

- VMA-Getzmann is renowned for manufacturing high-quality dispersing, mixing, and milling equipment, particularly for the chemical, coatings, and inks industries, specializing in engineered-to-order solutions that emphasize innovation, reliability, and technical excellence.

- Power

- 0.3 kW - 55 kW

- Speed

- 5.5 kW to 55 kW

- Product Capacity

- 0.05 litres - 2000 litres

- Control System

- CN / C / SC / PLC

- Automation

- PLC-controlled

- Milling Chamber Volume

- 0.05 litre - 2 litre

- Temperature Transfer

- Guided cooling water system

- Material of Milling Chamber

- High alloy stainless steel, ZrO2, SiSiC

- Safety Standard

- ATEX certified

- Operation Mode

- Single pass / Recirculation

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- Air incorporation control

- Available for vacuum systems

- Integration with existing systems

- Compatible with modular systems

- Operation in explosive environments

- ATEX certified

- Abrasion resistance

- High alloy steel, ZrO2 ceramic, SiSiC

- Corrosive resistance (e.g. acids)

- VITON, EPDM, Perfluoroelastomer O-rings

- Cleanability

- Ceramic or hard metal options for easy cleaning

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Tank Shape

- Toroidal / Cylindrical

- Tank Capacity

- 30–2000 litres

- Feed Method

- Gravity / Pneumatic

- Discharge Method

- Pneumatic / Gravity

- Control Panel Type

- PLC / Touchscreen

- Control panel type

- CN / C / SC / PLC

- Scraper system

- Available

- Modular quick-change systems

- Available

- Container sizes

- Multiple sizes available

- Milling system material

- Ceramic / hard metal / alloy steel

- Explosion-proof options

- Available

- Modular systems

- Bespoke configurations

- Sealing materials

- VITON / EPDM / Perfluoroelastomeres