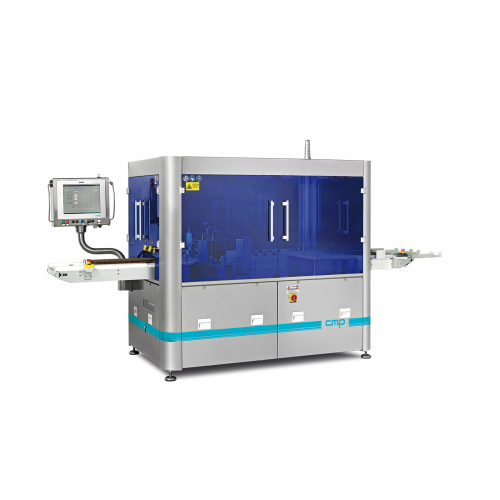

360 and leak Inspection system for glass containers

Ensure the integrity of every glass container with a comprehensive inspection system that combines high-speed leak testing and 360-degree visual analysis, critical for maintaining product quality and safety in liquid and freeze-dried products.

Inspects and Tests Glass Containers for Leaks

The RS Series from Marchesini Group combines CMP’s extensive know-how in visual inspection with cutting-edge High Voltage Leak Detection (HVLD) technology. Designed for pharmaceutical, biotech, and cosmetic industries, it excels in inspecting ampoules, vials, and cartridges across liquid and freeze-dried products. The machines perform 360° surface inspections using a rotation system and are equipped with four leak test stations. With a capacity handling range from 1 ml to 30 ml, the RS1 and RS2 models achieve production speeds of up to 400 units per minute. The compact design ensures seamless integration into existing production lines, while customization options include various lighting setups and CMP software for specific inspection needs. Constructed to meet GMP standards, the RS Series ensures compliance and reliability, supported by Marchesini’s global engineering and customer care network.

Benefits

- Ensures product integrity and compliance with comprehensive leak detection and defect inspection.

- Increases operational efficiency with high-speed processing of up to 400 units per minute.

- Customizable inspection parameters enhance adaptability to diverse production requirements.

- Compact design allows seamless integration into existing production lines, saving valuable space.

- GMP-compliant construction ensures adherence to stringent pharmaceutical and biotech standards.

- Applications

- Liquid formulations, Freeze-dried products, Cosmetics, Biopharmaceuticals, Pharmaceuticals

- End products

- Lyophilized pharmaceuticals, Vials, Ampoules, Cosmetic serums, Cartridges, Eye drops, Injectable drugs, Medicinal glass bottles

- Steps before

- Washing, Sterilizing, Filling

- Steps after

- Leak Testing, Labelling, Packaging

- Input ingredients

- ampoules, vials, cartridges, liquid products, freeze-dried products

- Output ingredients

- inspected ampoules, inspected vials, inspected cartridges

- Market info

- Marchesini is renowned for manufacturing high-quality packaging machinery for the pharmaceutical and cosmetics industries, offering innovative, customized solutions with advanced automation and technology.

- Automation

- Automatic inspection

- Leak Test Method

- High Voltage Leak Detection (HVLD)

- Inspection System

- Camera Visual Inspection

- Leak Test Stations

- 4 stations

- Rotation System

- 360° Total Surface Inspection

- Production Speed

- Up to 400 pcs/min

- Capacity

- 1 ml to 30 ml

- Supported Containers

- Ampoules, Vials, Cartridges

- Diameter Range

- 8 mm - 32 mm

- Height

- Up to 120 mm

- Customizability

- Back and Bottom Lights, CMP Software

- Inspection method

- Camera visual inspection

- Leak detection method

- High Voltage Leak Detection (HVLD)

- Automation level

- Automatic

- Productivity

- Up to 400 pcs/min

- Rotation system

- 360° total surface inspection

- Customizability

- Back and bottom lights, CMP’s software

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine Footprint

- Compact Design

- Capacity

- 1 ml - 30 ml

- Diameter Range

- 8 mm - 32 mm

- Height

- Up to 120 mm

- Production Speed

- Up to 400 pcs/min

- Rotation System

- 360° Total Surface Inspection

- Control panel type

- Touchscreen HMI

- Integration possibilities

- Software customization with CMP’s software

- Lighting options

- Combination of back and bottom lights