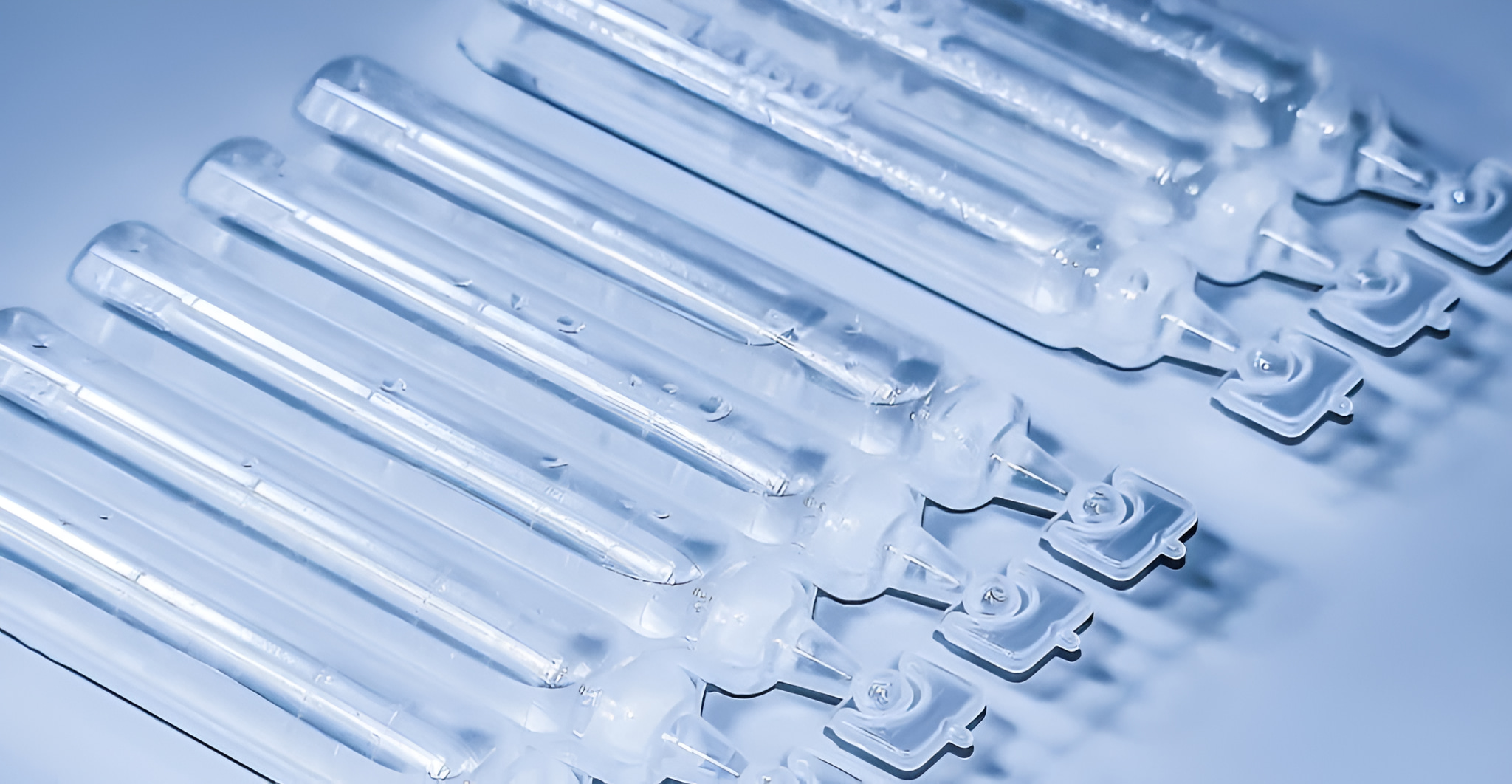

Visual inspection for small volume parenterals

Ensure pristine injectable solutions by detecting cosmetic and particle defects in vials with a fully customized visual inspection platform, optimizing both detection rates and inspection reliability for critical pharmaceutical production needs.

Inspects and Sorts Pharmaceutical Vials

The VISION CAV 600 and EVO CAX 20 from WILCO AG are engineered to address the rigorous demands of pharmaceutical and biotech inspection processes. These systems are designed for the automated visual inspection of particles and cosmetic defects in pharmaceutical vials, handling both liquid and lyophilized products. The VISION CAV 600 ensures maximum reliability with its static optical path OptiX, reducing vibrations and negating the need for operator adjustments during format changes. It supports scalable inspection tasks with customizable camera stations for high-resolution image capturing.

Applications span the inspection of various parenteral drug products, including injectable antibiotics, insulin solutions, and vaccines, ensuring adherence to high-quality standards. Both models operate with full automation, facilitating seamless integration into existing production lines. The EVO CAX 20 is tailored for high mix/low volume settings, boosting operational flexibility with quick format changes and AI-supported recipe development. These systems offer sustainable processing with a focus on reducing false reject rates and enhancing detection accuracy.

Their construction adheres to GMP guidelines, ensuring compliance and safety, while features like servo-driven spinning stations and vacuum gripper systems further boost operational efficiency. With capabilities for continuous operation at high speeds, these inspection systems accommodate intense production demands, promising consistent quality without relying on operator performance.

Benefits

- Ensures consistent, high-quality inspection results, reducing manual inspection variability.

- Lowers false reject rates, optimizing product yield and minimizing waste.

- Enhances operational flexibility with quick format changes, suitable for diverse production needs.

- Reduces labor dependency with fully automated, operator-independent functionality.

- Complies with GMP standards, ensuring regulatory adherence and safe pharmaceutical processing.

- Applications

- Parenteral drug products, Liquid formulations, Lyophilized products, Vials, High mix - low volume parenterals, Pharmaceutical products, Small volume parenterals

- End products

- Freeze-dried monoclonal antibody formulations, Peptide therapies, Vaccines, Chemotherapy drugs, Injectable antibiotics, Anticoagulant solutions, Insulin solutions, Diagnostic agents, Small protein therapy vials, Vitamin and mineral injections, Parenteral nutrition solutions, Reconstituted lyophilized vaccines, Intravenous hydration solutions, Liquid biologics, Hormonal injections

- Steps before

- Filling, Lyophilization, Batch Preparation

- Steps after

- Sterilization, Packaging, Labeling, Batch Release

- Input ingredients

- vials, liquid products, lyophilized products, pharmaceutical products

- Output ingredients

- inspected vials, quality control reports, detection rates data, defect identification results

- Market info

- Automation

- Fully Automated

- Speed

- Up to 20 vials per minute

- Capacity

- Handles 2R – 30R vials

- Inspection Stations

- Up to 13 stations

- Optical Path

- Static Optical Path (OptiX)

- Vial Transportation System

- Gentle Transport System

- Image Processing

- Scalable Processing Units

- Camera Stations

- Multiple High-resolution Cameras

- Customization

- Project-specific Inspection Algorithms

- Footprint

- Small / Compact Design

- Automation level

- Fully automated

- Batch vs. continuous operation

- Batch / Inline inspection

- Changeover time

- Fast

- CIP/SIP

- CIP 121°C / SIP 135°C

- Cleaning method

- CIP / Manual

- Energy efficiency

- High

- Inspection speed

- Up to 20 vials per minute per system

- Versatility in inspection

- High mix / low volume

- Inspection customization

- Project-specific algorithms

- Container transportation system

- Gently transport samples

- Inspection type

- Cosmetic and particle inspection

- Vial handling

- Vacuum gripper system

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Container size

- 2R - 30R vials

- Container type

- Vials, bottles

- Drug type

- Liquid, Lyophilized

- Inspection type

- Visual, Particle, Cosmetic

- Filling levels compatibility

- All levels

- Compact footprint

- Small footprint design

- Machine design

- GMP compliant

- Control panel type

- Operator-centered handling with hatched panel

- Vial transportation system

- Vacuum gripper system for smooth handling

- Discharge method

- Configurable sorting module with up to 8 outlets

- Inspection stations

- Up to 13 stations

- Optical path

- Static optical path OptiX

- Control panel type

- HMI or PLC

- Inspection algorithm selection

- Project specific

- Camera station configuration

- Adjustable spinning profiles