Laboratory mixer granulator

Achieve high-quality mixtures in R&D and small-batch production with versatile laboratory mixer granulators, designed to optimize processes such as mixing, coating, and granulation for precise development and testing of various formulations.

Mixes, Dryers, Coats, and Granulates Laboratory Samples

The L5, L10, L20, and L50 Ploughshare Mixers from Gebrüder Lödige Maschinenbau offer exceptional versatility for laboratory and product development applications. Utilizing a mechanically generated fluid bed, these mixers ensure thorough blending of powders, granules, and liquids, supporting processes like mixing, drying, and granulation. Suitable for industries from pharmaceuticals to food, the mixers are capable of generating homogeneous mixtures, making them ideal for creating products like tablet pre-mixes, mascara bases, and polymer granules.

Operating in batch mode, these units feature adjustable speed settings and optional choppers for enhanced mixing dynamics. Integration is seamless, thanks to manual control settings suited for research environments. With options for heating and cooling jackets and compliance with FDA materials standards, these mixers are designed for precise control over product quality. Each system supports CIP cleaning, facilitating easy maintenance and ensuring hygienic operation. For customized needs, the mixing tools and drum sizes are exchangeable, offering tailored solutions for specific process requirements.

Benefits

- Ensures consistent product quality across various batch sizes with mechanically generated fluid bed technology.

- Facilitates rapid product development through customizable mixing speeds and configurations.

- Minimizes contamination risk with easy-cleaning design and FDA-approved materials.

- Enhances operational flexibility with interchangeable drum sizes for diverse applications.

- Supports efficient process scaling from laboratory to production scale.

- Applications

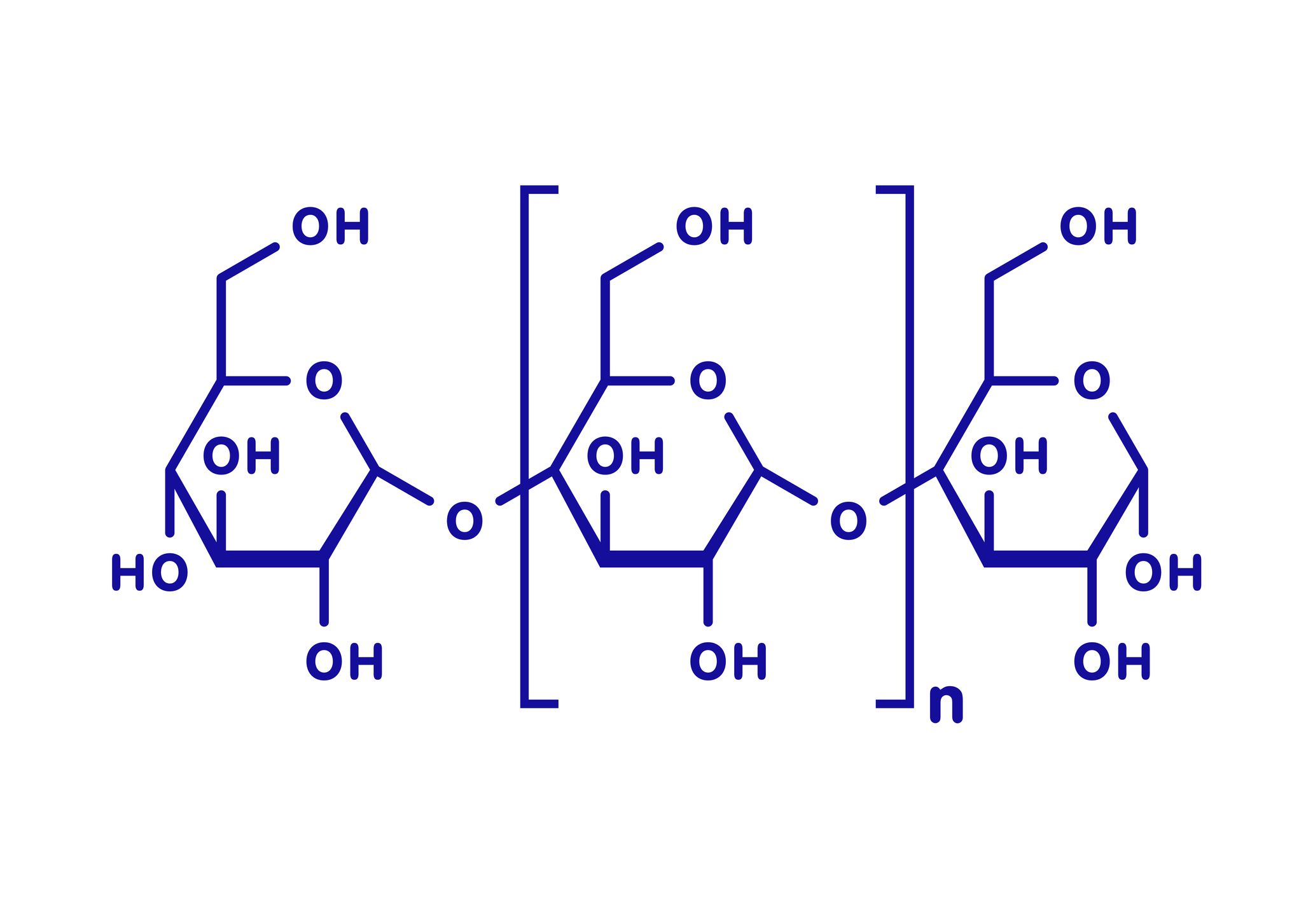

- Chemicals, Food, Polysaccharides, Metallurgy, Building materials, Cosmetics, Plastics, Batteries, Pharmaceuticals

- End products

- Dry mortars, Metallic powder blends, Mascara base formulations, Cornflakes, Anode and cathode mixtures, Polymer granules, Polymer dispersions, Tablet pre-mixes, Sugar coating solutions, Soft cheese blends, Eye shadow powders, Effervescent granulates, Lip balm bases, Decorative sugar blends, Plant-based fibers, Hair dye powders, Chemical reaction fertilizers, Raw material blends for solar cells

- Steps before

- Purification, Drying, Grinding

- Steps after

- Coating, Granulation, Drying, Packing

- Input ingredients

- bulk solids, powdery materials, grainy materials, fibrous materials, pumpable products, liquid formulation ingredients, binding agents

- Output ingredients

- mixed materials, homogeneous distribution, granulated products, coated particles, homogeneous particle size

- Market info

- Loedige Process Technology is renowned for its expertise in industrial mixing, granulation, drying, and coating technologies, offering engineered-to-order solutions for various industries, including pharmaceuticals, chemicals, and food processing.

- Drum volume

- 5, 10, 20, 50 liters

- Mixing principle

- Mechanical fluid bed

- Speed adjustment

- Continuously adjustable

- Material of construction

- Stainless steel

- Mixing element type

- Ploughshare shovels

- Additional features

- Choppers available

- Liquids addition

- Pipes or nozzles

- Heating and cooling

- Jacket available

- Working mechanism

- Mechanical fluid bed

- Integrated steps

- Mixing, granulation, coating

- CIP/SIP

- Manual cleaning

- Batch vs. continuous operation

- Batch

- Automation level

- Manual / PLC

- Changeover time

- Adaptable

- Cleaning method

- Manual/CIP options available

- Abrasion resistance

- High

- Biological compatibility

- FDA approved

- Cleanability

- Easy to clean, no "dead zones"

- Corrosive resistance (e.g. acids)

- Stainless steel construction

- Density/particle size

- Suitable for 0.5–2.5 g/cm³

- Temperature resistance

- Suitable for various temperature conditions

- Machine footprint

- Compact design, suitable for laboratory

- Drum volume

- 5, 10, 20, 50 liters

- Mixing drum shape

- Horizontal, cylindrical

- Discharge method

- Via outlet, side access for 50 L model

- Construction material

- Stainless steel

- Control panel type

- User-friendly control system

- Mixing element speed

- Continuously adjustable

- Discharge method

- Complete discharging possible

- Exchangeable drum sizes

- 5, 10, 20 litres