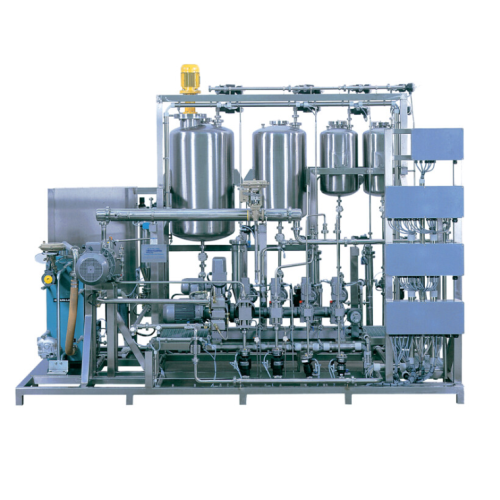

Automated body lotion blending system

Streamline your personal care product manufacturing with a seamless blending and emulsification system designed to maintain product integrity and consistency while maximizing throughput.

Mixes, Emulsifies, and Meters Liquid Formulations

The Bran + Luebbe AutoBlend System is expertly designed for precision in producing high-quality body lotions and personal care emulsions. It integrates a Bran+Luebbe PENTAX mixer for seamless mixing and emulsification within a continuous flow. This system features a fully automated, computer-controlled process with mass flow meters and LIV stream monitoring, ensuring a sterile operation and direct product transfer to the filling station. Ideal for manufacturers of moisturizing and cosmetic products, it supports a range of liquid formulations from body lotions to facial serums.

This system uses a type KH metering pump with electric delivery control and multiple plunger pump heads to maintain consistent product quality. The inclusion of pipe heat exchangers in sanitary design aids in cooling formulations, while on-line pH and viscosity analyzers ensure optimal product conditions. Automation is key, with full recipe management, product monitoring, and automatic shutdown capabilities when ingredients deplete, all contributing to efficient and reliable operation. The CIP system allows for flow-through cleaning and sterilization, minimizing downtime and ensuring compliance with hygiene standards.

Benefits

- Enhances product consistency and quality through precise metering and emulsification.

- Reduces labor costs with fully automated control and monitoring systems.

- Minimizes downtime with an integrated CIP system for efficient cleaning and sterilization.

- Ensures compliance with hygienic standards for personal care product manufacturing.

- Allows for continuous operation, improving productivity and reducing the risk of contamination.

- Applications

- Liquid formulations, Emulsions, Personal care products, Body lotion

- End products

- Hair conditioner, Anti-aging cream, Hydrating gel, Sunscreen lotion, Emulsion cleanser, Moisturizing body lotion, Hand cream, Facial serums, Aftershave balm, Liquid foundation

- Steps before

- Ingredient Preparation, Dispensing, Pre-mixing

- Steps after

- Cooling, Filling, Quality Control, Labeling, Packaging

- Input ingredients

- ingredient, body lotion components

- Output ingredients

- high-quality body lotion, sterile body lotion

- Market info

- SPX Flow is renowned for its expertise in manufacturing industrial ETO equipment, specializing in fluid handling and processing solutions. They are recognized for innovation, reliability, and providing efficient solutions across diverse industries, including food, beverage, and industrial markets.

- Automation

- Fully automatic process control

- Batch vs. continuous

- Continuous

- Cooling method

- Tube heat exchanger

- Online monitoring

- Mass flow meters, pH and viscosity analyzers

- Mixer type

- PENTAX dynamic mixer

- Pump type

- K and P metering pumps with plunger pump heads

- Cleaning method

- Automated CIP system

- Batch vs. continuous operation

- Continuous

- Automation level

- Fully automatic

- Air incorporation control

- No air introduction

- CIP/SIP

- CIP system included

- Cleaning method

- CIP

- Cleanability

- CIP-compatible

- Corrosive resistance (e.g. acids)

- Stainless steel construction

- Control panel type

- Computer-controlled system

- Discharge method

- Direct transfer to filling station

- Control panel type

- Computer-controlled

- Integration possibilities

- Recipe and product management with data report

- Automation level

- Fully automatic process control