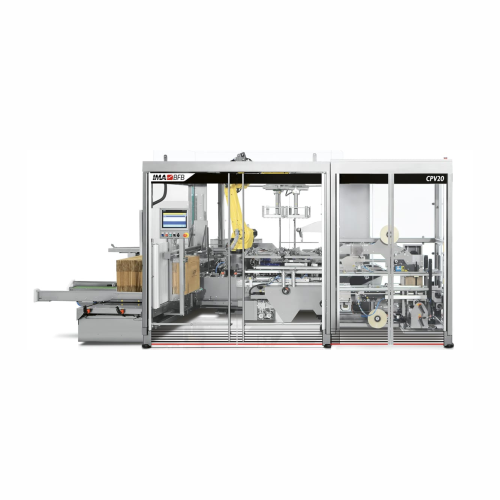

Top-loading case packer for pharmaceutical and cosmetic products

Ensure precision and flexibility in packaging with this modular top-loading case packer, perfect for handling diverse product shapes and enhancing production line efficiency.

Packs, Loads, and Closes Cases Efficiently

The CPV20 from IMA Group is a modular top-loading case packer designed to meet the needs of pharmaceutical and cosmetic manufacturers. Its cantilever and modular design provide complete accessibility and easy cleaning, facilitating seamless integration of special modules like booklet feeders and inspection systems. Capable of processing up to 20 cases per minute, the CPV20 efficiently handles various product forms, including blister packs, vials, and tubes. With automatic size changeover and high-speed operation, it ensures continuity in production without compromising accuracy. Available options for case closing include hot melt glue or adhesive tape, enhancing flexibility in packaging processes. The CPV20 can be paired with palletizers for streamlined end-of-line automation, effectively coordinating case buffering and pallet replacements in high-capacity environments.

Benefits

- Enhances productivity with up to 20 cases per minute throughput.

- Streamlines production transitions with automatic size changeover, reducing downtime.

- Offers flexible packaging options with both glue and tape case sealing.

- Integrates seamlessly with diverse product handling systems for versatile application.

- Optimizes end-of-line efficiency with modular palletizing solutions.

- Applications

- Cartons, Tubes, Cosmetics, Bottles, Bags, Pharmaceuticals

- End products

- Toothpaste cartons, Ointment tubes, Sachets of facial creams, Blister packs of tablets, Glass serum vials, Plastic shampoo bottles

- Steps before

- Product Collation, Product Infeed, Case Erecting

- Steps after

- Palletizing, Case Closing, Track, Trace Integration

- Input ingredients

- bottles, cartons, bags, tubes, loose products, bundled products

- Output ingredients

- packed cases, closed cases, palletized cases

- Market info

- IMA is known for its expertise in manufacturing automated packaging machines and solutions, particularly for the pharmaceutical, cosmetics, food, tea, and coffee industries, offering innovative, high-quality equipment and comprehensive customer service.

- Speed

- Up to 20 cases/minute

- Case Dimensions

- Min

- Automation

- Automatic size changeover

- Case Closing Method

- Hot melt glue or adhesive tape

- Integration Capability

- Track, Trace systems, sub-assemblies like booklet feeders or inspection cameras

- Product Handling

- Loose or bundled products, bottles, cartons, bags, tubes

- Collation Method

- Servo driven collation methods

- Accessibility

- Cantilever design for easy cleaning and complete accessibility

- Hopper Movement

- Driven movable hopper

- Magazine Loading

- Horizontal magazine for easy loading

- Working mechanism

- Top-loading case packing

- Automation level

- Automatic

- Batch vs. continuous operation

- Batch

- Changeover time

- Automatic size changeover

- Cleaning method

- Easy cleaning

- Integration capability

- Modular design for special modules

- Product handling flexibility

- Handles various shapes

- Ergonomics

- Ergonomic position of components

- Case closing method

- Hot melt glue / Adhesive tape

- Size handling capability

- Automatic size adjustment

- Integration with Track,Trace systems

- Yes

- Accessibility

- Cantilever design for complete accessibility

- Energy efficiency

- Designed for high productivity

- Cleanability

- Easy to clean, ergonomic design

- Biological compatibility

- Suitable for pharmaceutical use

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Container type

- Cartons, bottles, bags, tubes

- Container size

- Various dimensions from Min

- Product form

- Loose or bundled products

- Product packaging type

- Bundled bottles, single cartons, bags

- Compliance,Certifications

- Integration with Track, Trace systems

- Speed

- Up to 20 cases/minute

- Machine footprint

- Depends on configuration

- Control panel type

- Ergonomic

- Modular design

- Yes

- Discharge method

- Automated case unloading

- Case magazine positioning

- Low horizontal

- Integration of special modules

- Booklet feeder, inspection cameras

- Product handling systems

- Bottles, cartons, bags, tubes

- Case closing method

- Hot melt glue, adhesive tape

- Automatic size changeover

- Yes

- Palletizer integration

- RP2, RP4