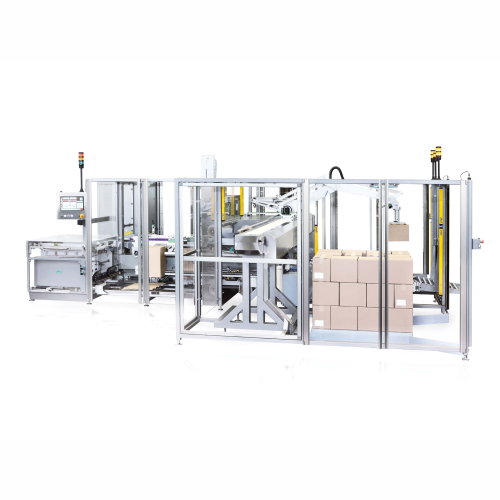

Automatic vertical case packer and palletizer for cosmetic sector

Optimize your packaging process with a compact solution that seamlessly combines product packing and palletizing, enhancing speed and flexibility through advanced robotic integration.

Packs and Palletizes Cosmetic Products Efficiently

The MCPV 850 from Marchesini Group is a compact, robotic vertical case packer-palletizer optimized for cosmetic and personal care product manufacturers. This machine excels in organizing loose products such as jars, bottles, cartons, and bundles, maintaining their upright positions for seamless packing and palletizing operations. Its robotized solutions enhance speed and flexibility, offering high throughput without sacrificing reliability. Production is fully automated using brushless motors controlled by a Siemens 677 PC, ensuring precision and reducing human intervention. Capable of handling a variety of packaging configurations, it accommodates product widths from 140 to 400 mm. The MCPV 850 operates with Europallets, maximizing space with its compact monobloc design. Customization options, such as printers, labellers, and check weighers, support tailored processing needs. Engineered for durability and efficiency, this system integrates smoothly into existing production lines, solving common logistical challenges in high-demand environments.

Benefits

- Enhances productivity by combining packing and palletizing in one seamless operation.

- Reduces operational costs with fully automated robotic control, minimizing manual labor.

- Offers versatile packaging solutions for diverse product types, maintaining their integrity.

- Optimizes space usage with its compact monobloc design, ideal for limited floor areas.

- Increases flexibility with customizable features, easily adapting to unique production requirements.

- Applications

- Personal care products, Jars, Cartons, Square bundles, Bottles, Cosmetics, Skincare products, Beauty products, Hair care products

- End products

- Hair dye kits, Face creams, Makeup remover bottles, Nail polish bottles, Toner bottles, Conditioner bottles, Hair gel cartons, Moisturizer jars, Sunscreen bottles, Soap boxes, Serum bottles, Foundation jars, Facial cleanser bottles, Lipstick bundles, Shampoo bottles, Mascara cartons, Body lotions

- Steps before

- Processing, Filling, Capping, Labelling

- Steps after

- Palletising, End-to-end Serialisation, Over-Wrapping, Banding, Shrinking

- Input ingredients

- loose products, jars, bottles, traditional cartons, square bundles

- Output ingredients

- packed cases, palletized products

- Market info

- Marchesini is renowned for manufacturing high-quality packaging machinery for the pharmaceutical and cosmetics industries, offering innovative, customized solutions with advanced automation and technology.

- Automation

- Fully automated

- Control System

- Siemens 677 PC

- Motor Type

- Brushless motors

- Product Handling

- Upright jars and bottles

- Customizability

- Printers, Labellers, Code Scanners, Check Weighers

- Dimension Range

- Width

- Pallet Size

- Europallet

- Total Pallet Height

- Stacks + pallet

- Automation level

- Fully automated

- Control system

- Siemens 677 PC

- Robotisation

- Advanced robotic solutions

- Flexibility

- High speed and flexibility

- Pack and palletize integration

- Combined operations in monobloc

- Ergonomic design

- Compact and ergonomic

- Motors

- Brushless motors

- Customisation options

- Printers, labellers, code scanners, check weighers

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Compact

- Control panel type

- Siemens 677 PC

- Discharge method

- Automated, Brushless Motors

- Control system

- Siemens 677 PC

- Drive type

- Brushless motors

- Integration with printers

- Available

- Integration with labellers

- Available

- Integration with code scanners

- Available

- Integration with check weighers

- Available

- Robotized solutions

- Enhances speed and flexibility