High-shear batch disperser for chemical and food industries

Achieve unmatched dispersion and emulsification precision with high-shear rotor–stator technology, ideal for processing challenging mixtures with minimal energy use and enhanced product consistency.

Performs High-Shear Dispersing and Emulsifying

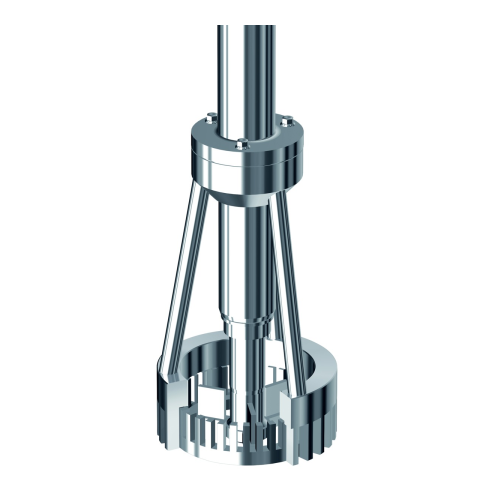

The YSTRAL X-Batch Disperser excels in providing high-shear dispersing and emulsifying solutions, specifically designed for challenging batch processing across industries such as chemicals, paints, and pharmaceuticals. Utilizing a robust rotor-stator principle, it achieves precise particle reduction and uniform distribution, ensuring superior mixing consistency. Its adaptably engineered dispersing tools cater to varying task-specific requirements, making it exceptionally versatile. The X-Batch Disperser supports seamless integration with existing process systems, offering flexible installation options including top, bottom, or lateral tank entry. With power capacities ranging from 1.5 to 55 kW and stepless speed control up to 3,600 rpm, it maintains high energy efficiency, reducing operational costs. Made from corrosion-resistant AISI 316 L stainless steel, it is suited for rigorous industrial conditions. Optional explosion-resistant design and diverse sealing options ensure safety and compliance with stringent industry standards. The equipment’s ease of maintenance, facilitated by its simple design and lifting frame operation, minimizes downtime and enhances productivity.

Benefits

- Ensures consistent product quality with uniform particle distribution.

- Reduces operational energy costs with efficient motor control.

- Adapts to diverse applications, maximizing versatility in production.

- Minimizes maintenance time with easy cleaning and robust design.

- Enhances safety with explosion-resistant features and secure installations.

- Applications

- Food, Inks, Coatings, Cosmetics, Chemical, Household, Paints, Pharmaceutical

- End products

- Steps before

- Pre-mixing, Powder handling, Liquid addition

- Steps after

- Homogenization, Filling, Packaging

- Input ingredients

- solids, liquids, suspensions, emulsions, solid components, liquid media, drops

- Output ingredients

- finely dispersed solids, finely dispersed liquids, homogeneous mixtures, dispersed suspensions, dispersed emulsions, homogeneous distribution

- Market info

- Ystral is known for its expertise in mixing, dispersing, and powder wetting technologies, providing high-quality engineered-to-order equipment solutions for industries such as chemicals, pharmaceuticals, and food, renowned for innovation, reliability, and efficiency in process optimization.

- Power

- 1.5 – 55 kW

- Voltage

- 230 / 400 V, 50 Hz, custom voltages possible

- Speed

- 1, 500 / 3, 000 min-1, stepless up to 3, 600 min-1 with frequency converter

- Seal

- Lip seal, mechanical seal single or double depending on application condition

- Options

- Explosion-resistant design, certificate, qualifications

- Diving part

- Stainless steel 1.4404 (AISI 316 L), special material

- Bearing flange

- Aluminium coated, 1.4404 (AISI 316 L)

- Circumferential speed

- 10 – 54 m/s

- Working mechanism

- Rotor-stator principle

- Comminution process

- High shear gradients

- Batch vs. continuous operation

- Batch dispersion

- Container contribution

- Directly in the container

- Air incorporation control

- No air entry

- Installation options

- Above, below, lateral, lifting frame

- Automation level

- Stepless speed control with frequency converter

- Energy efficiency

- High shear with minimum energy input

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Container size and shape

- Variable, tank installation from above, below, or laterally

- Installation method

- Tank installation from above, below or laterally or operation on the lifting frame

- Operation

- Batch dispersion directly in the container

- Control panel type

- Digital / Analog / HMI

- Integration possibilities

- Batch operation customization / Inline integration

- Seal type

- Lip seal, mechanical seal single or double

- Explosion resistance

- Explosion-resistant design available

- Custom voltages

- Available upon request