Batch mixer for powdery, granular, and fibrous materials

Achieve precise consistency and high batch reproducibility in your production process with a versatile mixer designed for efficient handling of diverse bulk materials, including powders, granules, and fibrous products. Ideal for operations needing reliable mixing, drying, or coating capabilities in batch modes.

Mixes and Processes Industrial Powders and Granules

The Ploughshare® Mixer FKM LS from Gebrüder Lödige Maschinenbau GmbH is engineered for versatile batch processing across diverse sectors, including chemicals, cosmetics, and pharmaceuticals. This horizontal mixer excels in uniform mixing of powders, granules, and fibrous materials, utilizing ploughshare components to achieve optimal consistency and batch reproducibility. It is designed for demanding applications, such as detergent powder and face cream production. Constructed from high-grade AISI 304L stainless steel with optional AISI 316L, it offers robust chemical resistance and longevity. Standard features include liquid feed nozzles, choppers, and thermometers, with an expandable design allowing retrofitting. The FKM LS supports efficient throughput and integration into existing production lines, ensuring seamless operation in both pre-processing and processing stages. With attention to energy efficiency, it ensures reduced operational costs. It complies with industry standards, including ATEX for explosion protection, making it suitable for sensitive chemical environments. The mixer’s design facilitates easy cleaning and maintenance, optimizing uptime and productivity.

Benefits

- Ensures consistent batch quality, enhancing product uniformity across various industries.

- Supports easy retrofitting, minimizing future upgrade costs and downtime.

- Provides robust resistance to chemical corrosion, extending equipment lifespan.

- Complies with ATEX standards, ensuring operational safety in explosive environments.

- Reduces operational costs with energy-efficient design and maintenance-friendly features.

- Applications

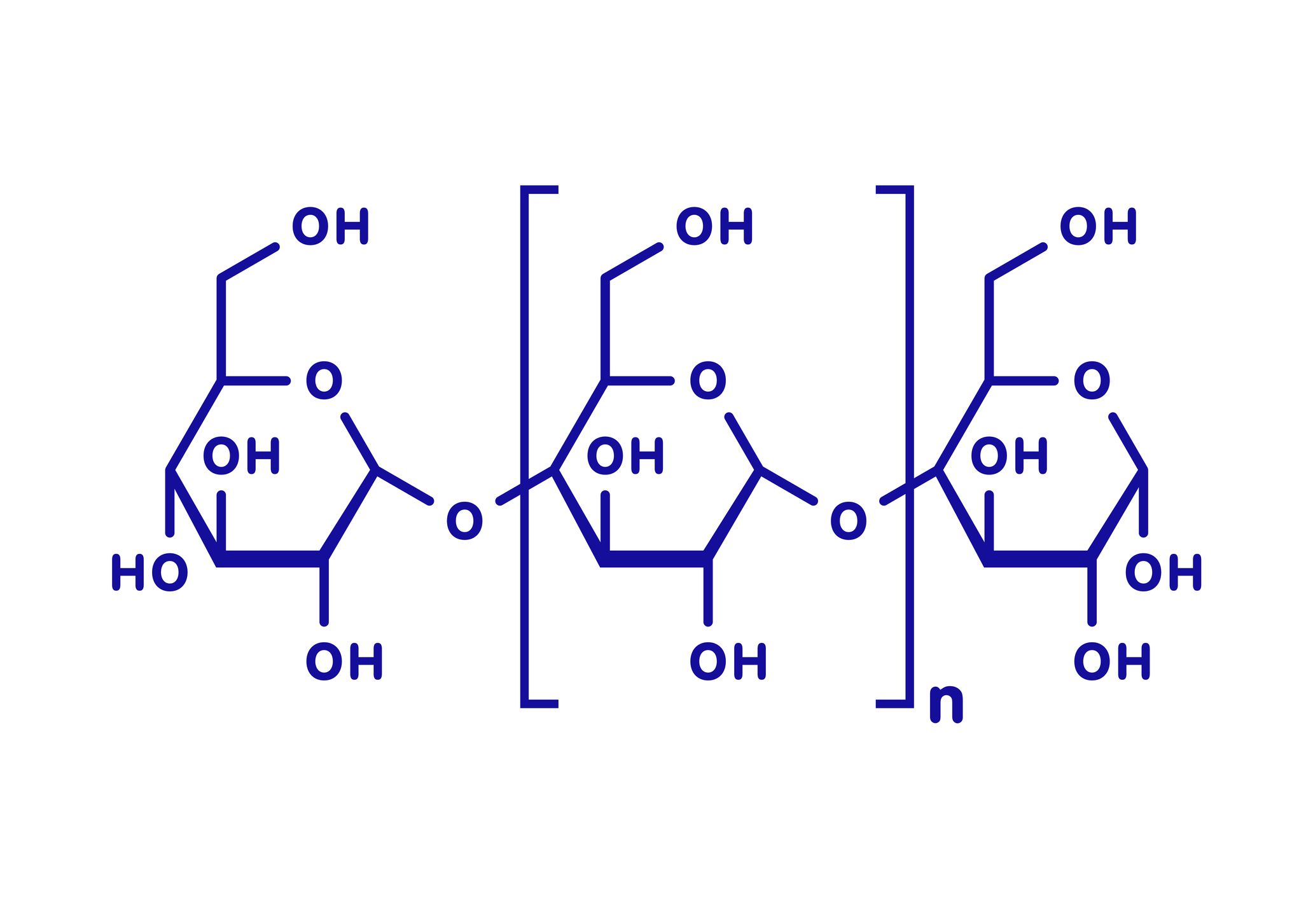

- Chemicals, Polysaccharides, Food, Building materials, Cosmetics, Batteries, Pharmaceuticals

- End products

- Detergent powder, Face creams, Mortar, Bread mix, Carboxymethyl cellulose, Tablet granules, Cathode masses

- Steps before

- Grinding, Granulation

- Steps after

- Drying, Coating, Packing

- Input ingredients

- powdery materials, granular materials, fibrous bulk materials, liquid feed

- Output ingredients

- mixed materials, homogeneous mixes

- Market info

- Loedige Process Technology is renowned for its expertise in industrial mixing, granulation, drying, and coating technologies, offering engineered-to-order solutions for various industries, including pharmaceuticals, chemicals, and food processing.

- Mixing Quality

- High

- Throughput Time

- Short

- Material Construction

- AISI 304L stainless steel

- Compatibility

- Powdery, granular, fibrous materials

- Liquid Feed Incorporation

- Nozzles for liquid feed lances

- Chopper Integration

- Yes

- Temperature Monitoring

- Thermometers included

- Retrofit Options

- Available

- Shaft Type

- Bolted and welded options

- Batch vs. continuous operation

- Batch

- Material Handling

- Powdery, granular, fibrous materials

- Mixing process

- Horizontal mixing

- Integration level

- Retrofit options available

- Manufacturing location

- Made in Germany

- Construction material

- AISI 304L stainless steel

- Abrasion resistance

- Yes

- Corrosive resistance (e.g. acids)

- Available with AISI 316L stainless steel

- Cleanability

- Design features for minimal dead space

- Density/particle size

- Suitable for powdery, granular, or fibrous materials

- Shape

- Horizontal

- Material

- AISI 304L stainless steel

- Feed method

- Liquid feed lances

- Stainless Steel Grade

- AISI 304L

- Material Grade Option

- AISI 316L

- Control System

- Basic Control System

- Additional Functionalities

- Retrofit Capabilities

- Nozzle Configuration

- Liquid Feed Lances

- Thermometer Integration

- Included

- Chopper Integration

- Optional

- Explosion Protection

- ATEX Explosions Protection

- Discharge Method

- Bolted/Welded Mixing Shaft