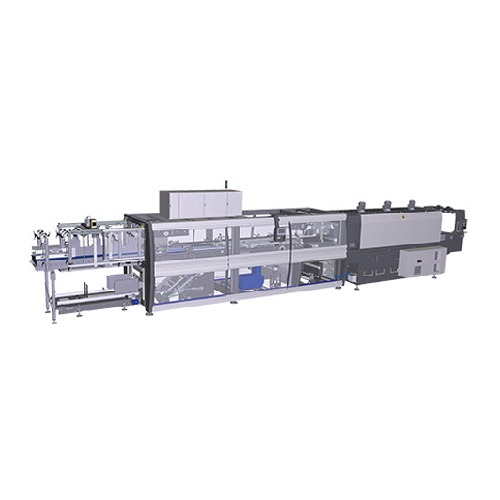

Film shrink wrapper with in-line infeed

Streamline your packaging line with advanced shrink wrapping technology designed to efficiently handle diverse container types, optimizing product protection and presentation while seamlessly integrating into existing production workflows.

Packs and Wraps Containers Efficiently

The LSK ERGON Series from SMI Group features automatic shrink wrapping machines purpose-built for high-speed packing and film wrapping of plastic, metal, cardboard, and glass containers. This series excels in addressing the diverse needs of the food and beverage, packaging, and consumer goods industries. Each model, such as the LSK 30 and LSK 40, integrates seamlessly into production lines, utilizing a mechanical product grouping system with both in-line and 90° infeed conveyors for flexible operations.

Capable of achieving outputs up to 40 packs per minute, the LSK ERGON machines cater to a variety of pack configurations, making them ideal for producers dealing with plastic bottles, metal cans, cardboard boxes, and glass jars. The incorporation of ICOS brushless motors with digital servo-drivers reduces energy consumption while ensuring precise film wrapping with a constant tensioning system and efficient heat-shrinking tunnel.

Constructed with a powder-painted steel frame and featuring for-life lubricated bearings, these machines offer durability and minimal maintenance downtime. The user-friendly POSYC® control panel provides intuitive operation, while modular mechanical and electronic components enhance operational flexibility and maintenance efficiency. Optional devices and configurations allow for tailored solutions, meeting the current and future packaging needs of your production environment.

Benefits

- Enhances operational efficiency with up to 40 packs per minute throughput.

- Reduces energy consumption through advanced ICOS brushless motor technology.

- Minimizes maintenance downtime with durable, easy-access design.

- Provides flexible packaging solutions with customizable pack configurations.

- Ensures precise film application with consistent tension control and advanced heat distribution.

- Applications

- Glass containers, Plastic containers, Metal containers, Cardboard containers

- End products

- Glass jars, Cardboard boxes, Plastic bottles, Metal cans

- Steps before

- Container preparation, Product grouping, Container alignment

- Steps after

- Shrink wrapping, Tray forming, Film unwinding, Packing, Heat shrinking

- Input ingredients

- plastic containers, metal containers, cardboard containers, glass containers, loose containers, corrugated cardboard pad, cardboard blank, film reel

- Output ingredients

- packs in film only, packs in cardboard pad + film, packs in cardboard tray, packs in cardboard tray + film

- Market info

- SMI Group is known for designing and manufacturing innovative packaging machinery and bottling plants. They provide cutting-edge solutions for ETO equipment, emphasizing flexibility, reliability, and efficiency in serving industries like food, beverage, and consumer goods.

- Speed

- Up to 40 packs per minute

- Packaging Type

- Shrink film, Pad + Film, Tray + Film, Tray only

- Lanes

- 1

- Container Type

- Plastic, Metal, Cardboard, Glass

- Pack Collations

- 2x2, 3x2, 4x3, 6x4

- Film Tensioning

- Progressive brake system

- Film Cutting

- Direct drive motorization

- Control Panel Type

- POSYC® touchscreen display

- Energy Efficiency

- Low energy consumption motors

- Motor Type

- ICOS brushless motors

- Changeover

- Manual

- Infeed Conveyor

- Thermoplastic material with low friction

- Modular Design

- Interchangeable components

- Shrink Tunnel

- Forced air ventilation

- Product Grouping System

- Mechanical

- Changeover time

- Manual

- Batch vs. continuous operation

- Continuous Inline

- Cleaning method

- Manual

- Automation level

- PLC Controlled

- Energy efficiency

- Low energy consumption motors

- User interface

- User-friendly touchscreen display

- Maintenance

- Easy and cost-saving

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- CE marking

- Yes

- ISO 9001

- Yes

- ISO 14001

- Yes

- Machine footprint

- Compact

- Frame material

- Sand-blasted and powder-painted steel

- Door material

- Anodised aluminium

- Conveyor material

- Thermoplastic with low friction coefficient

- Control panel type

- Interactive touchscreen display

- Film unwinding location

- Lower part of the machine

- Infeed type

- In-line or 90° infeed

- Control panel type

- Interactive 7'' touchscreen display

- Touchscreen display option

- 15'' model mounted on an arm sliding on rail

- Modular design

- Yes

- Infeed conveyor customization

- In-line or 90° infeed

- Pack format customization

- 2x2, 3x2, 4x3, 6x4

- Packaging type customization

- Shrink film, Pad + Film, Tray + Film, Tray only

- Motor type

- ICOS brushless motors with digital servo-driver

- Film tensioning system

- Progressive brake with tensioning spring

- Additional device integration

- Possible for enhanced functionality