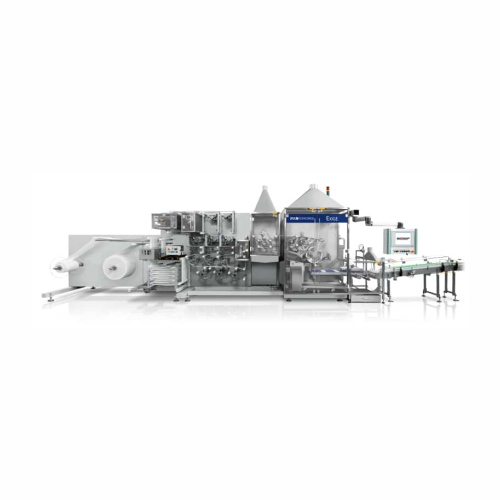

Wet wipe converting line for high-speed production

Optimize wet wipe production with a high-speed system that delivers precision folding, cutting, and wrapping while reducing waste and Total Cost of Ownership (TCO). Ideal for producing flushable and delicate substrates with minimal operator intervention.

Processes and Converts Wet Wipes Efficiently

The EXIGE Wet Wipe Converting Line from IMA Group is a fully automatic, high-speed platform designed to streamline the production of various wet wipe products, including baby wipes, antibacterial wipes, and flushable sanitary products. What sets the EXIGE apart is its vacuum-less folding mechanism, allowing high efficacy and low scrap rates. Achieving throughput of up to 3,600 wipes per minute, it supports production in personal care and home care industries by efficiently folding, wetting, cutting, and wrapping wipes. The system is highly adaptable, accommodating different substrate types, from delicate paper-based flushables to durable scrubbers, and is equipped with a customizable wetting system to precisely control lotion application.

The EXIGE line is fully PLC-controlled, offering integration with upstream and downstream processes. Its efficiency is demonstrated by a reduced Total Cost of Ownership (TCO), using less than 2% in materials wastage. Compliant with ATEX standards for handling flammable liquids and adhering to Pharma GMP for sanitary production, the EXIGE ensures minimal contamination risk. Its design avoids 90° turns, enhancing ergonomics and operator accessibility. Maintenance is straightforward, supported by linear motor stackers and full servo drive systems for reliable operation.

Benefits

- Increases production efficiency by achieving up to 95% operation effectiveness with minimal waste.

- Lowers total production costs with its vacuum-less folding, reducing material waste.

- Enhances safety with ATEX compliance for processing flammable liquids.

- Ensures product quality and safety through GMP-compliant design to minimize contamination risks.

- Improves flexibility in production with configurable wetting systems for diverse wipe applications.

- Applications

- Personal care products, Home care products, Flushable wipes, Wet wipes, Sanitary products

- End products

- Biodegradable wipes, Gentle touch sensitive skin wipes, Baby wipes, Antibacterial wipes, Heavy-duty scrubbing wipes, Floor cleaning wipes, Lotion-infused wipes, Make-up remover wipes, Skin cleansing wipes, Disinfectant wipes, Surface cleaning wipes, Isopropyl alcohol wipes

- Steps before

- Unwinding, Material preparation

- Steps after

- Wrapping, Quality control, Wetting, Packaging

- Input ingredients

- raw materials, sanitary substrates, cellulosic fibers, wood pulp, flushed substrates, rolls of paper-based material, isopropyl alcohol, flammable liquids

- Output ingredients

- cross-fold wipes, wet wipes, flushable wipes, sanitary wipes

- Market info

- IMA is known for its expertise in manufacturing automated packaging machines and solutions, particularly for the pharmaceutical, cosmetics, food, tea, and coffee industries, offering innovative, high-quality equipment and comprehensive customer service.

- Design speed

- 1500–3600 wipes/min

- Operating speed

- 1200–3200 wipes/min

- Stacking speed

- 100–200 stacks/min

- Linear speed

- up to 160 m/min

- Number of lines

- 2, 3, or 4

- Drive

- Full servo

- Stacker type

- Linear motor / Pneumatic cylinders

- Roll diameter

- 1200 mm | optional 1350/1500 mm

- Open wipe width

- 110–300 mm

- Open wipe length

- 150–200 mm | optional 300 mm

- Folded wipe length

- 75–100 mm | optional 200 mm

- Fold type

- Z, double Z

- Stack height

- 5–60 mm

- Count

- 5–40

- Quantity of lotion

- 200–300%

- Efficiency

- > 95%

- Waste

- < 2%

- Automation level

- Fully automatic

- Changeover time

- Minimal due to fully automatic setup

- Batch vs. continuous operation

- Continuous

- Cleaning method

- Not specified (assumed CIP due to high sanitary standards)

- Energy efficiency

- Reduced Total Cost of Ownership (TCO)

- Adjustability

- Multiple parameters under operator’s control

- Material handling capability

- Handles delicate paper-based flushables

- ATEX compliance

- Available for explosive environments

- Quality control

- Integrated Vision System

- Suitable for delicate substrates

- Yes

- Flushable paper-based materials

- Yes

- Alcohol-soaked wipes

- Yes, ATEX compliant

- Sustainability

- Cellulosic fibers

- Nonwoven materials

- Yes

- GMP Compliance

- Yes

- ATEX Certification

- Yes

- Pharma GMP Standards

- Yes

- Roll diameter

- 1200 mm | 1350 mm

- Number of lanes

- 2, 3, or 4 lanes

- Frame type

- Single or Double

- Control panel type

- HMI with multiple parameter adjustments