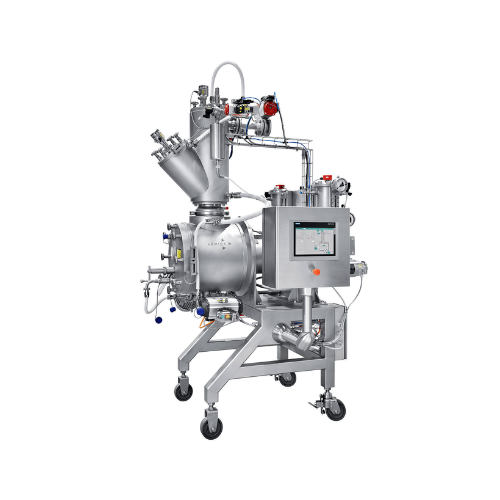

Vacuum paddle dryer for laboratory use

Achieve precise temperature and moisture control in your batches with this vacuum shovel dryer, designed for optimal mixing, drying, and granulation in laboratory settings. Perfect for R&D environments requiring reliable scale-up to production scales.

Mixes, Granulates, Dries, and Cools in Vacuum Conditions

The DRUVATHERM® Vacuum Shovel Dryer from Lödige Maschinenbau is a laboratory-scale drying solution engineered to handle complex drying, mixing, and granulation processes under vacuum conditions. Specially designed for R&D departments in industries such as chemicals, cosmetics, and pharmaceuticals, this equipment is adept at processing a variety of product types, including slurries, powders, and granules.

This horizontal batch vacuum dryer employs a frequency-controlled mixing tool installed in a cylindrical drum with a temperature control jacket. The unique mechanical design ensures a three-dimensional product movement, optimizing heat transfer and significantly reducing drying times. Its ability to simultaneously perform mixing and granulation makes it a versatile choice for labs needing precise scale-up to production levels.

Common end-products include chemical stabilizers, cosmetic creams, polymer pellets, and active pharmaceutical ingredients. The equipment supports solvent recovery effectively, which is crucial for cost management and environmental compliance.

Constructed with an emphasis on ergonomics and process engineering, the DRUVATHERM® features surfaces that are electrically polished to prevent product contamination. Moreover, it is available in drum sizes from 5 to 20 liters and is configurable for GMP standards, ensuring compliance in sensitive production environments like the pharmaceutical sector.

To enhance operational convenience, the system is entirely encased with laterally movable housing, facilitating easy maintenance and accessibility while ensuring safety.

Benefits

- Achieves precise moisture control for enhanced product quality and consistency.

- Facilitates efficient solvent recovery, reducing operational costs and environmental impact.

- Supports seamless scale-up from lab to production, reducing development time.

- Reduces drying times with optimized heat transfer, improving workflow efficiency.

- Offers GMP-compliant options for regulatory adherence in pharmaceutical applications.

- Applications

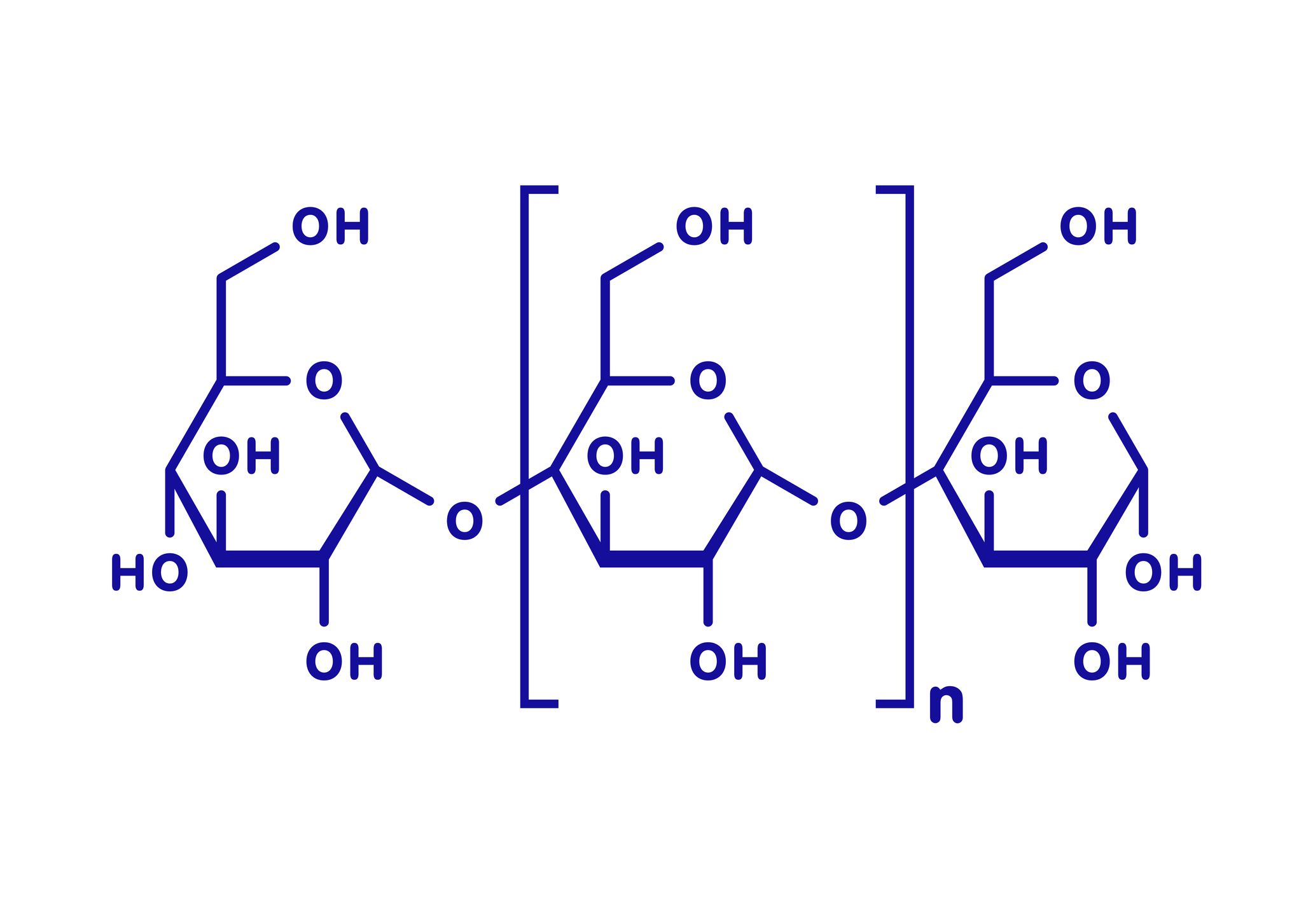

- Chemicals, Food, Polysaccharides, Cosmetics, Plastics, Batteries, Pharmaceuticals

- End products

- Electrode materials for batteries, Cosmetic creams, Powdered milk, Cellulose derivatives, Active pharmaceutical ingredients (apis), Polymer pellets, Chemical stabilizers

- Steps before

- Mixing, Granulation

- Steps after

- Cooling, Solvent Recovery, Packing

- Input ingredients

- suspensions, pastes, bulk goods, powders

- Output ingredients

- dried products, granules, dispersed powders

- Market info

- Loedige Process Technology is renowned for its expertise in industrial mixing, granulation, drying, and coating technologies, offering engineered-to-order solutions for various industries, including pharmaceuticals, chemicals, and food processing.

- Dryer Type

- Vacuum Paddle Dryer

- Batch Size

- 5–20 L

- Drum Size

- 5, 10, 20 L

- Mixing Tool

- Frequency-controlled

- Temperature Control

- Cylindrical mixing drum with temperature control jacket

- Mixing Movement

- Three-dimensional product movement

- Chopper Speed

- High speeds

- Mechanical Seal

- Double-acting

- Filtration System

- Pneumatic filter cleaning

- Operation Type

- Batch

- Product Heating

- Contact with heated device wall

- Working Mechanism

- Vacuum shovel drying with paddle mixing

- Integrated Steps

- Mixing, granulation, drying, cooling

- CIP/SIP

- Manual cleaning

- Batch vs. continuous operation

- Batch

- Temperature Control

- Temperature control jacket

- Product Movement

- Three-dimensional product movement

- Automation Level

- Integrated control system

- Energy Efficiency

- Cost-efficient solvent recovery

- Facility Space Requirement

- Compact design

- Abrasion resistance

- Yes

- Biological compatibility

- Yes

- Cleanability

- High

- Corrosive resistance (e.g. acids)

- Yes

- Density/particle size

- 0.5–2.5 g/cm³

- Batch processing capability

- Suitable for small batches

- Drying of suspensions

- Yes

- Tank shape

- Cylindrical

- Drum size

- 5, 10, 20 L available

- Control panel type

- Integrated control system

- Surface finish

- Industrial polishing/electrolytically polished

- Control panel type

- Integrated control system

- Mixing tool type

- Frequency-controlled

- Drum sizes available

- 5, 10, 20 L

- Pressure capability

- Available as a machine with internal pressure

- Materials available

- Special materials for parts in contact with product

- GMP standard/chemical design

- Available