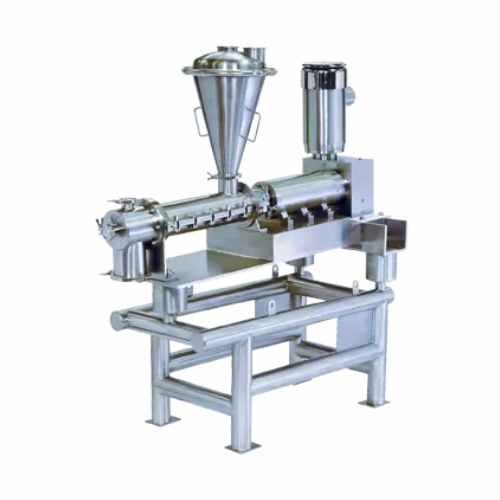

Mixer/extruder for viscous pastes and plastic masses

Achieve seamless mixing, kneading, and extrusion of viscous materials with integrated high-shear efficiency, ensuring uniform texture and consistency in your production process.

Mixes, Kneads, and Extrudes Continuous Batches

The Extrudomix from Hosokawa Micron is a multifunctional mixer-extruder designed for challenging continuous processing needs in chemical, food, and pharmaceutical industries. Combining high shear mixing, kneading, and extrusion in one compact unit, it efficiently turns solid, liquid, and powder inputs into uniform pastes and plastic masses. Featuring a single horizontal shaft with strategically arranged spiral blade segments, it processes materials continuously, ensuring consistent quality and particle dispersion. With capabilities to handle diverse applications such as producing protein bars, plant-based meats, and battery slurries, the Extrudomix integrates seamlessly into existing production lines. Its throughput varies across models, handling up to 4,550 kilograms per hour, with options for heating or cooling jackets tailored to specific process needs. Energy is conserved through an optimized motor system, lowering operational costs. The equipment offers material flexibility with various rotor sizes, enabling customization to specific production requirements. Additionally, it supports both continuous and batch operations, adapting to different production demands.

Benefits

- Enhances production efficiency by combining mixing, kneading, and extrusion in one unit.

- Lowers operational costs with reduced energy consumption through optimized motor control.

- Adapts to diverse product formulations with customizable rotor and die options.

- Improves product consistency with continuous high shear processing.

- Minimizes maintenance with robust design and optional CIP system for easy cleaning.

- Applications

- Chemicals, Food, Animal feed, Energy, Beverage, Metals, Cosmetics, Environment, Minerals, Pharmaceuticals

- End products

- Detergent powders, Reactor catalysts, Battery slurries, Pharmaceutical creams, Metal powders for additive manufacturing, Plant-based meat alternatives, Mineral suspension pastes, Custom pigments, Thickening agents, Cosmetic masks, Protein bars

- Steps before

- Grinding, Mixing base powders, Wet material mixing

- Steps after

- Homogenizing, Extrusion, Packing

- Input ingredients

- solids, liquids, wet material, base powders, homogenizing powders

- Output ingredients

- viscous pastes, plastic masses, homogeneous pastes, caked masses, extruded plastic mass

- Market info

- Hosokawa Micron is renowned for specializing in the manufacturing of powder and particle processing technologies, including mixing, drying, and milling equipment. They are respected for their innovative solutions and engineering excellence in industrial engineered-to-order equipment markets.

- Process area diameter

- 152-610 mm

- Approx. capacity

- 340-4550 kg/h

- Typical motor power

- 7.5-95 kW

- Die size

- Up to 5-6 mm

- Continuous mixing

- Yes

- Heating/cooling jackets

- Available on request

- Additional shear capabilities

- Yes

- Batch mixing alternative

- Available on request

- Material feeding

- Automatic

- Cooling or heating integration

- Jacketed housings or hollow shafts

- Die configuration

- Variety available

- A shaft seal

- For operation under pressure or vacuum

- Integrated containment systems

- Available for low OEL product

- Working mechanism

- Single horizontal shaft with blade segments

- Integrated steps

- Mixing, kneading, and extrusion in one unit

- Batch vs. continuous operation

- Continuous

- Shear capabilities

- High shear mixing

- Heating/cooling options

- Heating/cooling jackets and hollow shafts available

- Extrusion flexibility

- Variety of extrusion plates with different shapes and sizes

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Kneading suitability

- Plastic masses

- Machine footprint

- Compact design

- Feed/Discharge method

- Continuous

- Die size

- Up to 5-6 mm

- Heating/Cooling availability

- Jackets and hollow shafts on request

- Control panel type

- PLC-based

- Integration possibilities

- Modular integration with existing systems

- Extrusion die customization

- Variety of shapes and sizes up to 5 - 6 mm diameter

- Heating / Cooling options

- Heating/cooling jackets and hollow shafts available

- Shaft seal

- Operation under pressure or vacuum

- Containment systems

- Integrated containment for low OEL products