Vacuum dissolver for large batch production

Optimize your mixing processes with a versatile vacuum dissolver designed for high-capacity operations, ensuring consistent homogeneity in every batch.

Mixes and Disperses High-Viscosity Liquids

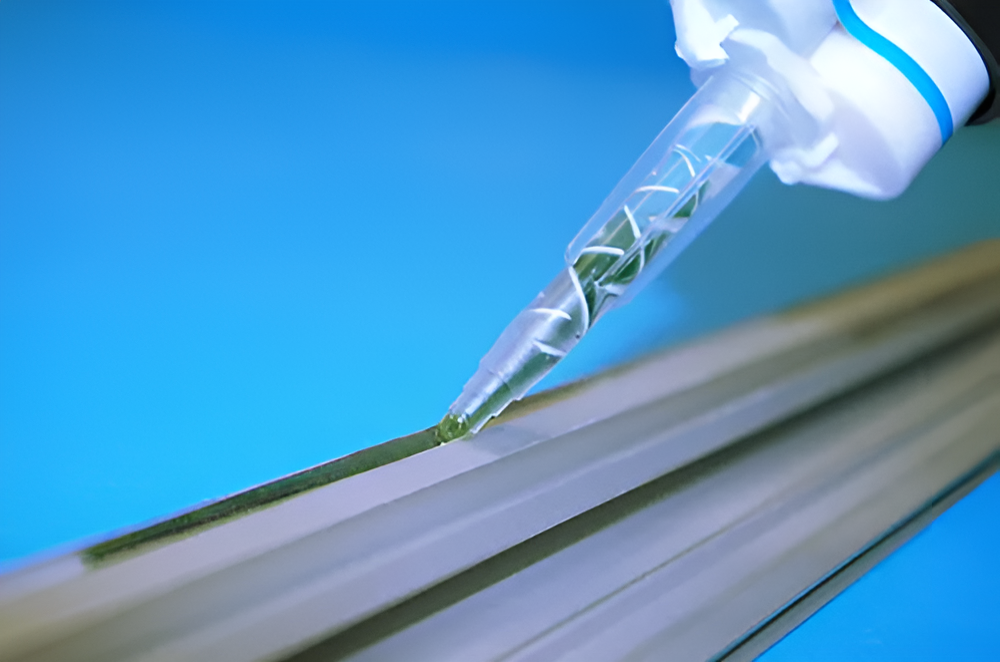

The DISPERMAT® SC4 dissolver from VMA-GETZMANN is engineered for high-performance mixing and dispersion of liquids across various industries, including agrochemistry and pharmaceuticals. This dissolver stands out with its robust motor capable of delivering a power range of 15-22 kW, ensuring efficient processing of batches up to 600 liters. Ideal for producing automotive coatings, lithium-ion battery slurries, or architectural paint emulsions, it uses advanced rotor-stator technology for uniform blend consistency.

With PLC integration, it offers precise control over mixing parameters, facilitating seamless integration into existing production lines. The dissolver’s design focuses on energy efficiency, reducing consumption by up to 30% with its optimized motor control. Constructed from corrosion-resistant materials, it is suitable for aggressive chemical environments. The DISPERMAT® SC4 complies with ATEX standards for safe operation in explosive atmospheres and offers an automated cleaning system, promoting hygiene and reducing downtime for maintenance. Customization options are available, allowing for tailored solutions to meet specific processing requirements.

Benefits

- Enhances efficiency with reduced power consumption by up to 30%.

- Minimizes maintenance downtime through automated cleaning systems.

- Complies with ATEX standards for safe operation in explosive environments.

- Integrates seamlessly into existing production lines with PLC control.

- Adapts to various chemical environments with corrosion-resistant materials.

- Applications

- Ceramics, Nano-applications, Artists, Buildings and colors, Polishing agents, Carbon materials, Silicones, Automobiles, Agrochemistry, Adhesives and sealants, Food products, Batteries, Pharmaceuticals

- End products

- Glazed ceramics, Spice pastes, Plant nutrient solutions, Structural adhesives, Silicone sealants, Cerium oxide polishing agents, Lcd display coatings, Acrylic artist paints, Lithium-ion battery slurries, Architectural paint emulsions, Automotive coatings, Carbon nanotube composites, Pharmaceutical nanoparticles

- Steps before

- Purification, Grinding, Mixing, Emulsification, Pre-dispersion

- Steps after

- Coating, Sterilization, Packing, Filling, Quality Control

- Input ingredients

- paint ingredients, active ingredients, slurries, fertilizer components, additives, color pigments, anode materials, cathode materials, conductive additives, binder materials, carbon black, ceramic pigments, spice particles, food additives, nanotubes, latex components, adhesive ingredients, sealants

- Output ingredients

- dissolved paint, homogeneous mixture, dispersed slurries, coating materials, finished fertilizer, uniform paint, battery electrodes, conductive coatings, finished pigments, food supplements, polished surfaces, ceramic glazes, cosmetic products, liquid crystal displays

- Market info

- VMA-Getzmann (Dispermat) is known for manufacturing high-quality dispersing, mixing, and milling equipment for laboratories and industrial settings, specializing in engineered-to-order (ETO) solutions with a reputation for innovation and precision.

- Power

- 0.3 - 55 kW

- Product Volume

- 0.05 - 2000 litres

- Control System

- PLC / CN / C / SC

- Speed

- Up to 20, 000 rpm

- Capacity

- 5.5 - 1000 litres/hour

- Cooling Temperature

- 4–15°C

- ATEX Certification

- Zone 0/1/2

- Batch Size

- 0.05 - 105 litres

- Batch Operation

- Batch/Inline Continuous

- Cleaning Method

- CIP / Manual

- Vacuum Capability

- Available

- Rotor-Stator Size

- SR03 - SR35

- Operating Temperature

- -60 to 100°C

- Automation

- PLC-controlled

- Power Input

- 0.1 - 25 kWh

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- CIP/SIP

- CIP 121°C / SIP 135°C

- Cleaning method

- CIP / Manual

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Container Size

- 30 – 2500 litres

- Scraper System

- Included/Optional

- Explosion protection standard

- ZONE 0/1/2

- Made in Germany

- SINCE 1972

- Quality Standard

- Precision, durable technology

- Control panel type

- CN / C / SC / PLC

- Container size

- 30 – 600 litres, 80 – 1000 litres, 400 – 2000 litres

- Control type

- CN / C / SC / PLC

- Control type

- ATEX (C / SC / PLC)

- Control type

- TM / C / PLC

- Control type

- Manual / PLC

- Drive speed adjustability

- Infinitely adjustable

- Rotor-stator compatibility

- SR03, SR04, SR17, SR20, SR30, SR35

- Vacuum design option

- Available

- Explosion protection

- ATEX ZONE 0/1/2

- Modular system

- Yes