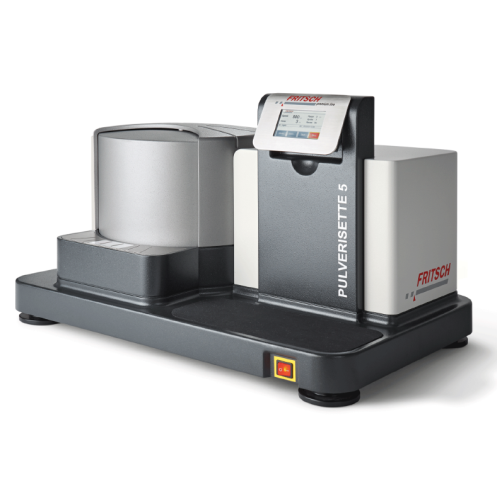

Planetary mill for nano grinding

Achieve precise nano-scale particle production and uniformity for demanding research environments through advanced planetary milling, enhancing the development of cutting-edge materials and technologies.

Grinds and Homogenizes Materials into Nanoparticles

The Planetary Mill PULVERISETTE 5 premium line from FRITSCH is designed for high-precision grinding, mixing, and homogenizing materials into nanoparticles. Utilizing a dual grinding station, it operates based on the planetary principle, achieving efficient comminution via high-energy impact and friction. This mill is optimized for applications in geology, materials research, and nanotechnology, producing rock samples, metal alloys, and ceramic powders. With ServoLOCK clamping, it ensures operational safety by preventing start-ups in unsafe conditions. Capable of processing up to 2 x 225 ml, it supports up to eight programmable settings, integrating with optional MillControl software for enhanced monitoring. The equipment is available with various grinding bowl materials to prevent contamination and support inert gas use, ensuring versatility across chemical, biological, and pharmaceutical applications.

Benefits

- Achieves precise particle size reduction, enhancing the quality of materials for advanced applications.

- Ensures user safety and equipment reliability with automated ServoLOCK clamping and imbalance shutoff.

- Reduces contamination risk through customizable grinding bowls and materials.

- Supports rapid prototyping and R&D with flexible program settings and real-time monitoring.

- Enhances processing efficiency with high centrifugal acceleration and dual grinding stations.

- Applications

- Ceramics, Chemistry, Mineralogy, Metallurgy, Geology, Biology, Mechanical alloying, Catalytic converters, Materials research, Nanotechnology, Batteries, Silicon-based lithium-ion batteries, Pharmaceuticals

- End products

- Nanoceramic materials, Drug formulations, Silicon anodes for lithium-ion batteries, Nanoparticles, Rock samples for mineral analysis, Biochemical compounds, Ceramic powders, Soil samples, Catalytic converter powders, Composite materials, Metal alloys

- Steps before

- Sample Preparation, Pre-crushing, Weighing

- Steps after

- Particle Analysis, Sample Examination, Quality Control

- Input ingredients

- hard samples, medium-hard samples, soft samples, brittle samples, moist samples, materials for mechanical alloying, rock samples, ceramic honeycomb body, soil sample, aluminium oxide sample, silicon particle geometries, catalytic converters

- Output ingredients

- nano range particles, powder, ground sample material, homogenized samples, mechanical alloys, silicon-based lithium-ion batteries, nanoparticles

- Market info

- Fritsch is renowned for manufacturing high-quality, engineered-to-order laboratory instruments for sample preparation and particle sizing in research and industrial laboratories, with a strong reputation for precision, innovation, and reliability.

- Drive Power

- 2.2 kW

- Centrifugal Acceleration

- up to 64 g

- Rotational Speed of Bowl

- up to 1600 rpm

- Useful Capacity

- up to 2 x 225 ml

- Number of Grinding Stations

- 2

- Sample Processing Capability

- Simultaneous processing of up to 4 samples

- Automation

- ServoLOCK clamping

- Automation Shutoff

- Automatic shutoff function

- Bowl Detection

- RFID chip

- Software Compatibility

- MillControl, USB interface

- Program Storage

- Up to 8 programmes

- Grinding Range

- Nano range

- Grinding Principle

- Planetary Principle

- Working Principle

- Planetary

- Clamping Method

- ServoLOCK motor-driven

- Automation Level

- Intuitive touchscreen operation

- Batch vs. Continuous Operation

- Batch

- Safety Features

- Automatic shutoff and block in case of imbalance

- Abrasion resistance

- Yes

- Biological compatibility

- Yes

- Cleanability

- Easy to clean

- Corrosive resistance (e.g. acids)

- Yes

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Sample capacity

- Up to 2 x 225 ml

- Sample type

- Hard, medium-hard, soft, brittle, and moist samples

- Application fields

- Geology, Mineralogy, Metallurgy, Ceramics, Materials Research, Nanotechnology, Pharmaceuticals, Chemistry, Biology

- Machine Footprint

- Compact

- Grinding Stations

- 2

- Grinding Bowl Sizes

- 125 ml, 150 ml, 250 ml, 420 ml, 500 ml

- Useful Capacity

- up to 2 x 225 ml

- Control Panel Type

- Intuitive touchscreen

- Discharge Method

- Automatic clamping system

- Control panel type

- Intuitive touchscreen operation with colour display

- Integration possibilities

- USB interface for transmission of process parameters

- Software capabilities

- MillControl for automatic control and monitoring

- Clamping system

- Motor-driven ServoLOCK clamping of the grinding bowls

- Program storage

- Up to 8 programmes can be saved

- Grinding bowl sizes

- 125 ml, 150 ml, 250 ml, 420 ml, 500 ml

- Materials for grinding bowls and balls

- Various materials for optimized results and contamination reduction

- Safety features

- Automatic shutoff function, RFID chip for bowl detection