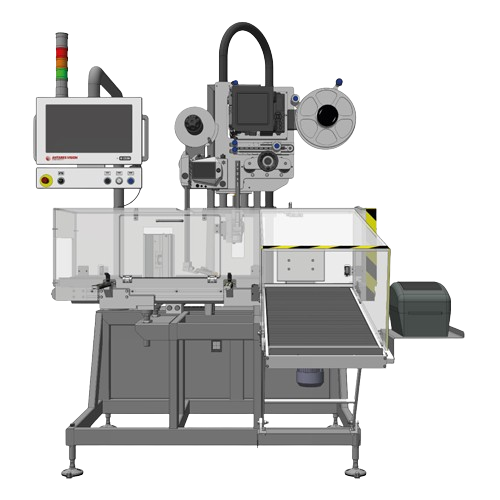

Standalone print & apply station for bottle and carton aggregation

Streamline your packaging operations by automating the precise aggregation, labeling, and verification of packaged units, ensuring seamless integration and efficiency in high-speed production lines.

Aggregates and Labels Packaged Units

The Print & Apply Station VM2900 from Antares Vision Group is engineered to streamline the aggregation and labeling of packaged units within pharmaceutical, cosmetics, and food packaging industries. This standalone, high-speed system accommodates various package types, including syrup bottles and blister packs, ensuring precise label application and verification through an integrated camera system. The VM2900 supports in-line integration, functioning seamlessly alongside existing bundling machines, and can manage bundle sizes ranging from 50 to 300 mm in width. It features a thermal transfer print and apply module for superior label quality and reliability. Designed with versatile outfeed and rejection system directions, it adapts easily to your production line layout. Compliance with industry standards ensures compatibility with pharmaceutical manufacturing requirements, while a user-friendly HMI allows for straightforward recipe management and operation. Its robust construction offers durability, and optional OCR/OCV capabilities enhance label accuracy by verifying human-readable characters, promoting traceability across the supply chain.

Benefits

- Enhances production efficiency with high-speed automated aggregation and labeling.

- Minimizes errors through integrated 1D/2D code recognition and verification system.

- Adapts to various production layouts with configurable outfeed and rejection directions.

- Ensures process reliability with robust thermal transfer printing technology.

- Streamlines operations with a single, user-friendly HMI for easy management.

- Applications

- Cartons, Consumer goods, Cosmetics, Industrial applications, Food packaging, Packaged units, Pharmaceutical packaging, Healthcare products, Bottles

- End products

- Medical device packaging, Food supplement packages, Shampoo cartons, Blister packs, Syrup bottles, Skincare packaging, Ready-to-eat food packs, Electronic component bundles

- Steps before

- Bundling, Item codes reading

- Steps after

- Packing, Shipping, Distribution

- Input ingredients

- bottles, cartons, packaged units

- Output ingredients

- bundles, aggregated bundles, applied labels

- Market info

- Antares Vision is renowned for providing inspection, track and trace, and quality control systems primarily to the pharmaceutical, food, and beverage industries, ensuring product integrity and supply chain transparency.

- Bundle/Case Size (A)

- 50-300 mm

- Bundle/Case Size (B)

- 15-250 mm

- Bundle/Case Size (C)

- 45-300 mm

- Working Height

- 800-1000 mm

- Number of Cameras for Aggregation

- 1

- Label Application

- Flat application on three sides

- Line Direction Option

- Linear / 90 degrees

- Print,Apply Module

- Thermal transfer with peel plate labeller applicator

- Manual Printing

- Thermal transfer unit on integrated tray

- Camera Controls

- 1D/2D code recognition

- Optional Controls

- OCR/OCV on human readable characters

- Aggregation Method

- Bottle/Carton-to-Bundle

- Label Application

- Three-Sided Flat Application

- Line Direction

- Linear / 90 Degrees

- Rejection System Configuration

- Linear / 90 Degrees

- Operation Interface

- Single HMI

- Inspection Technology

- 1D/2D Code Recognition

- Camera System

- Dedicated Camera for Aggregation

- Printing Method

- Thermal Transfer

- Operational Modes

- Full Aggregation / Labelling Only

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Configurable layout

- Working height

- 800-1000 mm

- Standard bundle/case size

- A = 50-300 mm / B = 15-250 mm / C = 45-300 mm

- Label application

- Flat application on three sides

- Single HMI

- For easy operations and recipe management

- Integration possibilities

- Upstream bundling machine

- Control panel type

- Single HMI

- Outfeed group layout direction

- Linear or 90 degrees

- Rejection system direction

- Linear or 90 degrees

- Machine configurations

- Varied according to format size