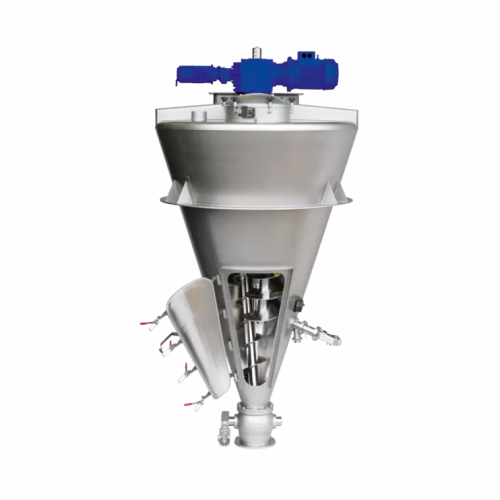

Batch mixer for segregative, free-flowing powders and pastes

Achieve precise and gentle batch mixing for delicate products with advanced conical screw technology, ensuring high mixing accuracy and minimal power consumption for effective processing of powders, pastes, and slurries.

Mixes and Blends Powders, Pastes, and Slurries

The Nauta® Conical Screw Mixer from Hosokawa Micron stands out for its ability to achieve high mixing accuracy without compromising the integrity of delicate materials. Its convective mixing mechanism utilizes a rotating screw suspended from an orbital arm, ensuring efficient axial, radial, and tangential mixing. This equipment is ideal for applications spanning pharmaceuticals, food, and cosmetics, where precise mixing of powders, pastes, and slurries is crucial.

With a capacity ranging from 5 to 100,000 liters, it supports varying batch sizes and production scales. Capable of operating in all ATEX zones, it ensures safety and compliance for explosive environments. PLC-controlled systems allow seamless integration into automated production lines, while an energy-efficient design minimizes power consumption. Constructed from durable materials like stainless steel, it offers excellent resistance to corrosion, critical for industries handling aggressive chemicals and materials.

Certified to meet the stringent standards of GMP and FDA, the mixer supports applications in pharmaceutical and food industries. Maintenance is simplified with features such as CIP/SIP capabilities and easy access for component inspection, ensuring downtime is minimized. Customization options, such as intensifier rotors and liquid injection systems, provide additional flexibility to meet specific processing requirements.

Benefits

- Enhances product consistency with high mixing accuracy and gentle handling.

- Minimizes operational costs with energy-efficient motor design.

- Ensures safety and compliance in explosive environments with ATEX approval.

- Streamlines maintenance with CIP/SIP capabilities for reduced downtime.

- Adapts to specific processing needs with customizable ancillary options.

- Applications

- Detergent powders, Plant-based proteins, Cosmetics, Nuclear applications, Minerals, Catalysts, Chemicals, Polymers, Additive manufacturing, Crop protection, Recovered carbon black, Animal feed, Metals, Cell culture media, Plastics, Pharmaceuticals, Battery materials, Marine algae, Food and beverages, Apis, Pigments and coatings

- End products

- Ibuprofen apis, Lithium-ion battery cathodes, Infant formula, Laundry detergent capsules, Epoxy coatings, Polyethylene pellets, Glyphosate herbicide, Tofu, 3d printed geometries, Soy protein isolate, Recombinant protein media, Spirulina powder, Sheet metal compounds, Bentonite clay, Polyethylene terephthalate (pet), Uranium fuel pellets, Carbon black filler, Foundation makeup, Chicken feed pellets, Titanium dioxide pigment, Automotive catalysts, Paracetamol tablets

- Steps before

- Grinding, Emulsification

- Steps after

- Drying, Coating, Packing

- Input ingredients

- free-flowing powders, segregative powders, pastes, slurries, liquids

- Output ingredients

- mixed powders, coated powders, granulated materials, dried products, moistened powders, coated solids

- Market info

- Hosokawa Micron is renowned for specializing in the manufacturing of powder and particle processing technologies, including mixing, drying, and milling equipment. They are respected for their innovative solutions and engineering excellence in industrial engineered-to-order equipment markets.

- Mixing capacity

- 5–100, 000 litres

- Screw speed

- 70 rpm

- Arm rotation speed

- 1–2 rpm

- Tip speed of screw

- 0.5–2 m/s

- Mixing accuracy

- High

- ATEX approval

- Yes

- Energy efficiency

- Very energy-efficient

- Heat input

- Atmospheric or vacuum with liquid recovery

- Motor power (typical)

- 2.2–90 kW

- Vessel diameter

- 145–700 cm

- Vessel height

- 175–900 cm

- Height incl. motor

- 225–1030 cm

- Batch vs. continuous operation

- Batch

- Mixing method

- Convective mixing

- Automation level

- Manual / PLC

- Energy efficiency

- Low power consumption

- Cleaning method

- Accessible for CIP

- CIP/SIP

- Suitable for CIP

- Control interface

- PLC controlled

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Suitable for delicate mixing

- Yes

- Particle Type

- Powders, Pastes, Slurries, Liquids

- Granulation capability

- Yes

- ATEX certification

- Yes

- ISO 14001

- Yes

- Ecovadis Silver Medal

- Yes

- Vessel diameter

- 145–700 cm

- Vessel height

- 175–900 cm

- Height incl. motor

- 225–1030 cm

- Volume capacity

- 2.5–100, 000 litres

- Discharge method

- Ball segment valve

- Cone shape

- Conical

- Feed type

- Powders and pastes

- Control panel type

- HMI/PLC

- Integration possibilities

- Modbus/Profibus/SCADA

- Sampler installation

- CIP/SIP compatible

- Lump breaker replacement

- Lump-beaker plug

- Charging hopper

- Single/Dual-person operation

- Liquid injection system

- Spray through hollow shaft