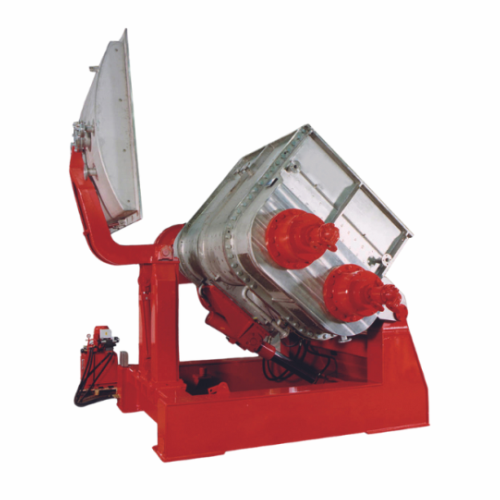

Double z-arm industrial extrusion kneader for high-viscosity processes

Optimize high-viscosity material processing with a double z-arm kneader designed for efficient blending and extrusion. Ideal for tackling demanding mixing tasks, this solution enhances productivity in continuous operations by ensuring thorough and uniform material consistency.

Kneads, Mixes, and Extrudes High-Viscosity Materials

The GUITTARD MX series from HASLER Group features double Z-arm industrial extrusion kneaders, perfect for tackling high-viscosity kneading challenges. This robust equipment excels in kneading, mixing, and extruding materials like lithium-ion battery slurries and epoxy adhesives. With a working capacity of up to 10,000 liters, it’s ideal for industrial-scale operations. The GUITTARD MX series ensures seamless integration into continuous production lines while delivering efficient torque transfer through its rugged drive mechanism. Options include electric or hydraulic drive systems, and configurations with stationary or tilting units, catering to diverse operational needs. Built with corrosion-resistant materials and designed to meet international standards, this series offers reliability and custom engineering support to adapt to specific application requirements.

Benefits

- Ensures uniform kneading with minimal dead zones, enhancing product consistency.

- Adaptable to various production demands through customizable configurations.

- Increases equipment longevity with a heavy-duty drive mechanism, reducing maintenance needs.

- Seamlessly integrates into continuous processes, improving production efficiency.

- Optimizes material handling with high-capacity capability, supporting diverse product types.

- Applications

- Chemicals, Food, Ceramics, Plastic compounds, Hydrometallurgy, Coatings and adhesives, Cosmetics, Batteries, Fertilizers

- End products

- Mascara formulations, Chocolate truffles, Lipstick bases, Ammonium nitrate, Uv-curable coatings, Ceramic tiles, Gold cyanide solution, Polypropylene resin, Inkjet inks, Lithium-ion battery slurries, Chewing gum base, Phosphoric acid, Polyethylene blend, Epoxy adhesives, Acrylic sealants, Copper concentrate, Porcelain teeth

- Steps before

- Mixing, Grinding, Emulsification

- Steps after

- Extrusion, Forming, Packing

- Input ingredients

- Nitrogen, Phosphorus, Potassium, Calcium, Magnesium, Copper, Gold, Silver, Zinc, Aluminium, Sealants, Bulk technical silica, Specialist polymers, Resins, Radioactive waste, Bayer aluminium, Alumina, Plastics, Carbon, Graphite, Glues, Mastics, Adhesives, Paints, Pigments, Inks, Colours, Toners, Lubricants, Clay, Alumina, Silica, Ceramic pigments, Resins, Adhesives, Solvents, Polymers, Pigments, Plaster, Polyethylene, Polypropylene, Polystyrene, Additives, Essential oils, Waxes, Emulsifiers, Preservatives, Colourings, Lithium, Nickel, Cobalt, Electrolytes, Oils, Food colourings, Chocolate, Sweets, Chewing gum, Additives, Crystallised fruits

- Output ingredients

- Uniform mix, Kneaded materials, Extruded products, Mixed and dispersed materials, Sheared materials, Processed materials

- Market info

- HASLER Group is known for manufacturing and supplying industrial engineered-to-order (ETO) equipment, specializing in mixing, filtration, and sealing solutions for various industries, with a reputation for quality and innovation in handling challenging process applications.

- Kneading capacity

- Up to 10, 000 litres

- Drive system

- Electric or hydraulic

- Blade type

- Double Z-arm

- Kneading action

- Sigma blade shearing

- Torque transfer

- Efficient torque transfer

- Extrusion screw

- Equipped

- Loading and unloading options

- Stationary, tilting, or bottom valve

- Thermal control

- Insulated trough design for heating/cooling

- Rotation speeds

- Differential rotation speeds

- International standards

- CODAP, ASME, TÜV

- Kneading Mechanism

- Double Z-arm with sigma blades

- Operation Type

- Batch/Continuous

- Torque Transfer

- Efficient torque transfer via arm positioning

- Drive System

- Electric or hydraulic

- Automation Level

- PLC / SCADA

- Customization Option

- Modular design for process adaptation

- Loading/Unloading Method

- Stationary, tilting, or bottom valve

- Temperature Control

- Heated/Cooled blades with internal channels

- Capacity

- Up to 10, 000 litres

- Safety Features

- Explosion-proof components

- Integration Capability

- Extrusion screw for continuous processes

- Material Coverage

- Extensive tank coverage

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Agglomeration risk

- Yes

- Tank Volume

- Up to 10, 000 litres

- Blade Design

- Double Z-arms

- Kneading Chamber

- Trough-shaped

- Drive System

- Self-contained, ultra-heavy-duty

- Tank Coverage

- Extensive coverage

- Blade Movement

- Zigzag pattern

- Drive System Type

- Electric or hydraulic

- Unit Type

- Stationary or tilting

- Unloading Type

- Bottom valve unloading

- Customisation

- Modular design

- Extrusion Screw

- For process optimization

- Material Heating/Cooling

- Insulated trough design

- Control panel type

- PLC / SCADA

- Drive systems

- Electric / Hydraulic

- Units

- Stationary / Tilting

- Customisation

- Modular design for application-specific needs

- Arm drive

- Independent blade arm drive with differential rotation speeds

- Extrusion screw

- To enhance kneading and forming

- Option

- Heated or cooled blades