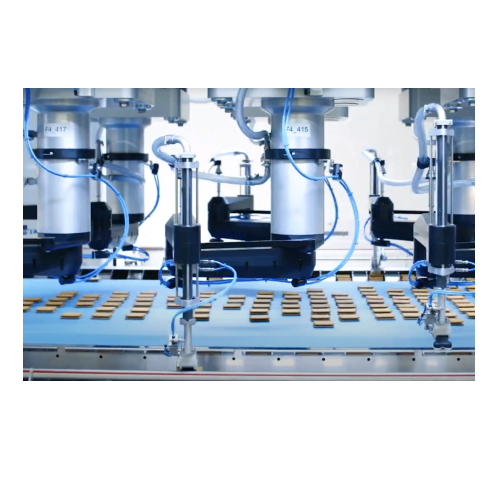

Pick & place robots for industrial packaging

Elevate your production line with advanced automation that ensures precise packing, adaptable handling, and robust quality control across diverse product types, delivering high-speed and scalable solutions that align with evolving market demands.

Automates Packaging and Ensures Quality Control

The pick & place packaging robots from Schubert offer a seamless solution for automating intricate packaging processes across multiple industries, including food, pharmaceuticals, and cosmetics. Utilizing patented counterflow principles and integrated Scara or Delta robots, these systems guarantee high-speed, precise operation. Suitable for diverse products—from chocolate biscuit rolls to pharmaceutical vials—these machines ensure continuous, adaptable packaging, enhancing your production line with reliable quality control through advanced image processing. With scalable configurations and modular components like tray destackers and chain conveyors, Schubert’s solutions support effortless integration and customization. Built for energy efficiency, these robots reduce operational costs while maintaining optimal throughput. Ideal for harsh industrial environments, their robust design ensures durability, while tools such as easily exchangeable grippers enhance flexibility for multiple formats. Schubert’s machines comply with industry standards, ensuring your production meets the highest quality requirements.

Benefits

- Enhances production efficiency with seamless integration into existing lines.

- Supports diverse product handling with flexible gripper tools.

- Ensures high-quality packaging with built-in image processing and quality control.

- Reduces operational costs with energy-efficient robot design.

- Minimizes changeover time with quick, tool-free format adjustments.

- Applications

- Food, Beverages, Snacks, Pet food, Confectionery, Cosmetics, Pharma, Bakery products, Dairy

- End products

- Liquid beverage containers, Flow-packed snacks, Plastic blister packs replacements, Chocolate biscuit rolls, Pet food pouches, Nature-based cosmetics, Carton-packaged dairy products, Pharmaceutical vials, Fresh or frozen bakery goods

- Steps before

- Product Sorting, Quality Inspection, Feeding Product onto Belt

- Steps after

- Packaging, Packing in Cartons, Palletizing, Labeling for Dispatch

- Input ingredients

- bakery products, confectionery, snacks, dairy products, beverages, cosmetic products, pharmaceutical products, pet food, sticky products, greasy products, frozen products, soft products, fragile products, pressure-sensitive products, heat-sensitive products, touch-sensitive products

- Output ingredients

- packaged bakery goods, packaged confectionery, packaged snacks, packaged dairy products, packaged beverages, packaged cosmetic products, packaged pharmaceutical products, packaged pet food, cartons, trays

- Market info

- Schubert Group is renowned for its innovative packaging technology solutions, specializing in modular, highly flexible packaging machines for various industries, ensuring efficiency and precision in production lines.

- Automation

- PLC-controlled

- Robot Type

- Scara or Delta

- Control System

- Single control system

- Image Processing

- Integrated, with position and shape detection

- Performance Scalability

- 1 to 6 T5 robots per machine frame

- Tray Destacker

- Included

- Chain Conveyors

- Adjustable, one or two

- Vision System

- Scalable

- Gripper and Suction Tools

- Easy-to-change, wide format range

- Additional Functions

- Upgradable with carton erector and closer

- Automation level

- High

- Integrated with modular systems

- Changeover time

- Minimal due to easy-to-change gripper and suction tools

- CIP/SIP

- Not specified

- Cleaning method

- Not specified

- Batch vs. continuous operation

- Continuous inline with modular flexibility

- Energy efficiency

- Unspecified, designed for high efficiency

- Built-in quality control

- Image processing and position detection

- Flexibility

- High

- Wide range of product and format compatibility

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Sensitivity to Handling

- Heat-sensitive / Pressure-sensitive

- Product State

- Sticky / Greasy / Frozen / Soft / Fragile

- Material Type

- Pharmaceutical / Cosmetic

- Container Type

- Carton / Tray

- Packaging Format

- Flowpack / Carton / Tray

- Compact footprint

- Yes

- Discharge method

- Wide belt via counterflow principle

- Control panel type

- Integrated control system

- Robot Variants

- Scara or Delta

- Gripper and Suction Tools

- Easy-to-change

- Robot type

- Scara / Delta

- Gripper and suction tools

- Interchangeable

- Control system

- Integrated single system

- Vision system

- 3D image processing

- Format changeover

- Easy, few steps

- Additional functions

- Carton erector, carton closer, leaflet insertion

- Robot tools

- 3D-printed format parts

- Lightline variant

- Available with shorter delivery time