In-line aggregation module for serialized item management

Optimize your serialization process by seamlessly managing and verifying serialized items before they enter the aggregation and packing stages, ensuring precision and efficiency in high-speed production environments.

Verifies and Aggregates Serialized Items

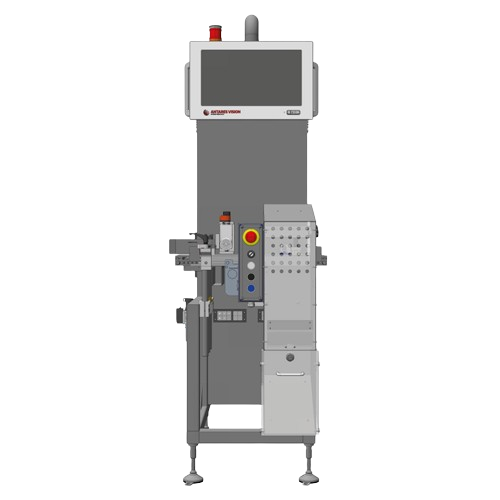

The Sentinel VM0900 from Antares Vision Group is a standalone module that excels in managing serialized items in constrained spaces on a production line. This compact device is tailored to verify serialization and perform aggregation upstream of bundling and case packing machines. Ideal for pharmaceuticals, cosmetics, and food products, it ensures each serialized item is scanned and validated, avoiding the unnecessary rejection of entire bundles. Operating at line speeds up to 300 pieces per minute, the Sentinel VM0900 integrates smoothly with existing systems, leveraging thermal inkjet (TIJ) or laser printing technology to ensure clear, readable data. Its conveyor length and modular design accommodate a range of carton sizes, and its robust construction ensures reliable performance in high-speed, inline operations. Designed for compliance with stringent industry standards, it supports the entire serialization process with precision, making it invaluable for packaging departments dedicated to maintaining serialized product integrity.

Benefits

- Optimizes production space by integrating aggregation in limited areas.

- Minimizes waste with precise item rejection before bundling.

- Enhances operational efficiency with line speeds up to 300 pcs/min.

- Ensures high-quality, readable serialization with advanced printing technology.

- Maintains product integrity in compliance with industry serialization standards.

- Applications

- Serialized items, Cosmetics, Packaging, Food products, Pharmaceuticals

- End products

- Serialized food containers, Blister packs, Serialized medication cartons, Snack packaging, Cosmetic bottles

- Steps before

- Serialization, Upstream Processing

- Steps after

- Aggregation, Bundling, Case Packing

- Input ingredients

- serialized items, serialized products

- Output ingredients

- bundled items, case packed items, rejected single items

- Market info

- Antares Vision is renowned for providing inspection, track and trace, and quality control systems primarily to the pharmaceutical, food, and beverage industries, ensuring product integrity and supply chain transparency.

- Line Speed

- Up to 300 pcs/min

- Working Height

- 800-1000 mm

- Conveyor Length

- 600 mm (800 / 1000 mm optional)

- Standard Carton Size (A)

- 30-120 mm

- Standard Carton Size (B)

- 15-100 mm

- Standard Carton Size (C)

- 45-220 mm

- Printing Technology

- TIJ

- Printable Sides

- 3

- Printing Heads

- Up to 4

- Printing System

- TIJ 2.5 including print controller

- Ink Cartridge Options

- Antares Vision Pharma Black (water based) or Industrial Black (solvent based)

- Max Resolution

- 600 dpi

- Datamatrix Print Quality

- Grade B typical

- Up to grade A on selected backings acc. to ISO/IEC 15415-2

- Laser Printing Heads

- Up to 3 (1 each printable side)

- Line Speed

- Up to 300 pcs/min

- Infeed Queue Management

- Standalone module for in-line aggregation

- Automation Level

- Automatic item serialization and rejection

- Rejection System

- Single item rejection before aggregation

- Compact Design

- Designed for limited space availability

- Printing Technology

- TIJ and Laser

- Scan and Verify

- Serialization status and data correctness

- Working Height

- 800 – 1000 mm

- Conveyor Length

- 600 mm (800 / 1000 mm optional)

- Cleanability

- Easy to clean

- Abrasion resistance

- High

- Compatibility with TIJ and Laser Printing

- Yes

- Standard Carton Size (mm)

- A = 30-120 / B = 15-100 / C = 45-220

- ISO/IEC 15415-2

- Datamatrix print quality

- Compact footprint

- Compact device design

- Machine footprint

- Not specified

- Working height

- 800-1000 mm

- Conveyor length

- 600 mm (800 / 1000 mm optional)

- Standard carton size

- A = 30-120 mm / B = 15-100 mm / C = 45-220 mm

- Printing heads

- Up to 4

- Printable sides

- 3

- Working height

- 800-1000 mm

- Conveyor length

- 600 mm (800 / 1000 mm optional)

- Standard carton size

- A = 30-120 / B = 15-100 / C = 45-220 mm