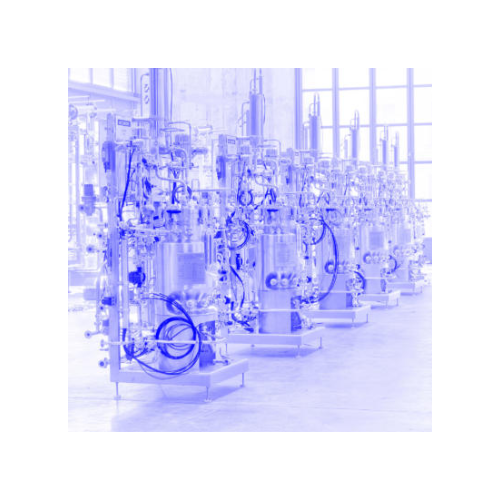

Modular bioreactor for low-volume production

Optimize your bioprocessing with a scalable solution designed for precise control and flexible operation, from pilot studies to full-scale production.

Facilitates Sterilization, Mixing, and Environmental Control

The NLF Bioreactor from Bioengineering AG stands out as a modular and reliable solution for diverse production needs, including biopharmaceuticals, cosmetics, and nutritional products. Distinguished by its adaptable design, it allows precise control over essential processes like sterilization, mixing, and gassing, ensuring consistency and quality. With a processing capacity of 11 to 20 liters, it supports both scale-up and scale-down operations, making it ideal for research and development as well as pilot production. This system integrates seamlessly into production lines with its automated sterilization (SIP) and cleaning (CIP) capabilities and offers flexibility through multiple stirrer and gas module options. Crafted from durable stainless steel, the NLF Bioreactor meets FDA and GMP standards, reflecting its compliance and suitability for pharmaceutical and food applications. Additionally, BioSCADA software ensures sophisticated control and data collection, facilitating efficient operation and monitoring. Tailored to meet specific customer requirements, the NLF Bioreactor promises reliable support for your production processes.

Benefits

- Enhances efficiency through modular design adaptable to various production scales.

- Ensures product quality and compliance with FDA and GMP standards.

- Minimizes operational costs with integrated automated sterilization and cleaning systems.

- Facilitates precise process control with advanced BioSCADA software.

- Offers versatility across multiple industries, from biopharmaceuticals to cosmetics.

- Applications

- Homeopathy, Food and nutritional products, Perfumes, Alternative medicine, Performance materials, Cosmetics, Biopharmaceuticals, Chemical, Petrochemical, Pharmaceutical

- End products

- Oral vaccines, Fragrances, Monoclonal antibodies, Vitamin supplements, Skincare serums, Homeopathic remedies, Herbal extracts, Petrochemical intermediates, Specialty polymers, Probiotics

- Steps before

- Sample Preparation, Inoculation, Media Preparation, Sterilization

- Steps after

- Harvest, Quality Control, Data Analysis, Product Analysis

- Input ingredients

- media, buffer, organisms

- Output ingredients

- biomass, bioproduct, exhaust gases

- Market info

- Bioengineering is known for its expertise in designing and manufacturing customized bioreactors and fermenters, serving the biotechnology and pharmaceutical industries. They are reputed for high-quality, engineered-to-order solutions and innovative process technologies.

- Processing capacity

- 11 / 13 / 20 liters

- Vessel material

- Stainless steel, double shell, double floor

- Drive types

- Top drive, bottom drive, Vibromixer

- Stirrer types

- Rushton, propeller stirrers, pitched-blade stirrers

- Ventilation options

- Venting pipe, ring sparger, sinter sparger, surface gassing, bubble-free gassing

- Temperature circuit and sterilization

- Electrical heating / Cooling water, steam heating / Cooling water

- Measurement and control technology

- Speed, temperature, pH, pO2, antifoam/level, redox, OD, weight, exhaust analysis

- Gas modules

- Up to 8 individual gassing lines with pulsed valves or mass-flow controllers

- Pump modules

- Up to 6 pumps

- Cleaning method

- Manually / CIP

- Automation levels

- Several available

- Configuration

- Up to 6 bioreactors controllable with a single control unit

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch

- CIP/SIP

- CIP 121°C / SIP 135°C

- Cleaning method

- CIP / SIP / Manual

- Biological compatibility

- Yes

- Cleanability

- Yes

- Corrosive resistance (e.g. acids)

- Yes

- Machine footprint

- Compact

- Tank shape and size

- 11 / 13 / 20 liters

- Vessel material

- Stainless steel, double shell, double floor

- Drive type

- Top drive, bottom drive, Vibromixer

- Stirrer type

- Rushton, propeller, pitched-blade stirrers

- Gassing method

- Venting pipe, ring sparger, sinter sparger, surface gassing, bubble-free gassing

- Control panel type

- Touchscreen HMI

- Integration capabilities

- SCADA, PLC

- Automation levels

- Manual / PLC / BioSCADA

- Bioreactor configuration

- Single / Multi / Production Plant Integration

- Combinable optional components

- Yes