Homogenizer for high viscosity liquids and solid suspensions

Struggling with homogenizing high-viscosity ingredients and ensuring even suspension of solids? This advanced stirring system offers dynamic mixing for consistent results, reducing energy consumption and increasing efficiency in your production line.

Mixes and Homogenizes High-Viscosity Media

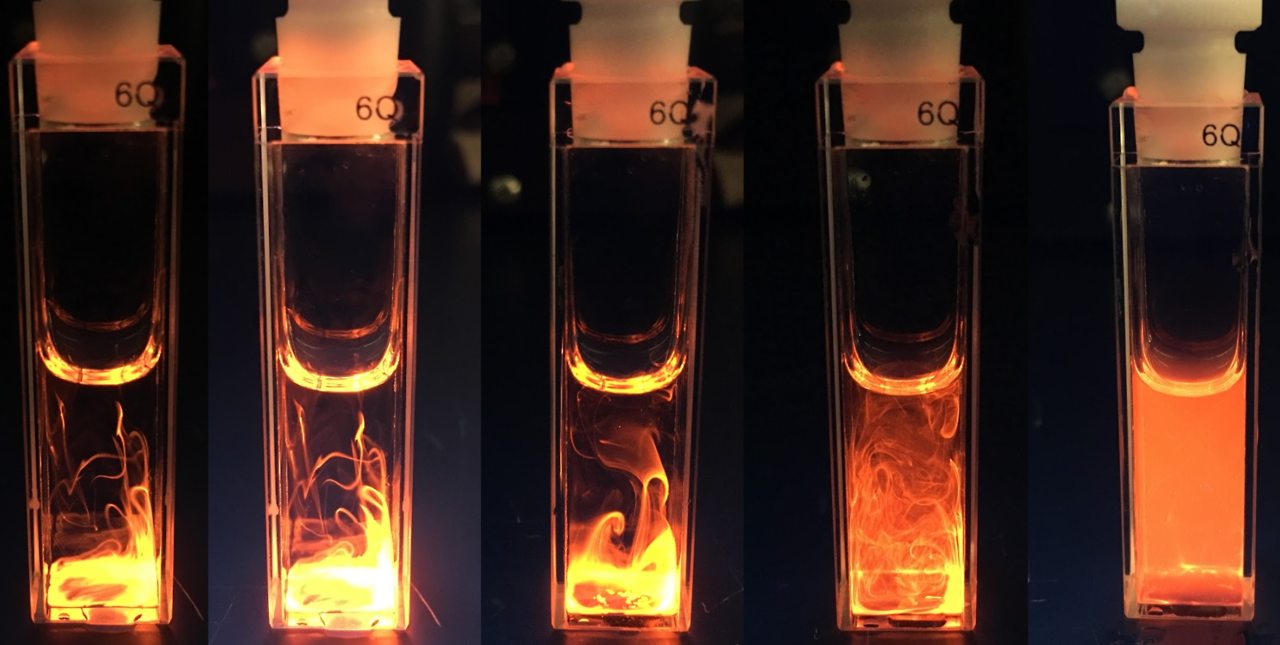

The VISCO JET® SPIRAL, part of the VISCO JET® Rührsysteme line, is designed for efficient mixing and homogenizing of high-viscosity media. It operates through dynamic mixing motions created by accelerated laminar flows and turbulence at the spiral’s entry and exit points. This technique ensures optimal dispersion of solids in liquids, making it suitable for applications in industries such as food, cosmetics, and chemical suspensions. It efficiently processes materials like tomato paste, acrylic paint, and polymer suspensions. The system offers low energy consumption due to its optimized motor control and supports integration with existing production lines, featuring compatibility with multiple stirring setups. Offered in stainless steel construction (grades 1.4301, 1.4404, 1.4571), it resists corrosion and supports a clean-in-place system for easy maintenance. Custom sizes and materials, including Superduplex and Hastelloy, cater to specific operational needs.

Benefits

- Enhances production efficiency with rapid homogenization of high-viscosity substances.

- Minimizes energy costs through efficient motor control and low operational speeds.

- Maintains consistent product quality by preventing foam formation and air entrapment.

- Offers sustainable processing with reduced wear and lower energy demands.

- Facilitates easy integration and maintenance with CIP compatibility and versatile material options.

- Applications

- Construction materials, Coatings, Cosmetics, Chemical suspensions, Food paste, Paints, Pharmaceuticals

- End products

- Cementitious grout, Emulsion paint, Acrylic paint, Gel capsules, Polymer suspensions, Tomato paste, Lipstick

- Steps before

- Material Feeding, Pre-mixing, Initial Mixing, Pre-heating

- Steps after

- Homogenization, Product Analysis, Quality Control, CIP Cleaning, Product Packaging

- Input ingredients

- hochviskose Medien, Feststoffe, Pasten, Pulver, Körnungen

- Output ingredients

- homogenisierte Medien, suspendierte Feststoffe

- Market info

- Visco Jet Ruhrsysteme is known for manufacturing advanced mixing and stirring equipment, particularly industrial agitators, which are engineered-to-order for various industries. Their expertise lies in efficient and tailored mixing solutions with a strong reputation for innovation and quality.

- Applicable Media Viscosity

- Up to 100, 000 mPas

- Mixing Mechanism

- Accelerated laminar flow at cone exit

- Turbulence at cone entry and between spirals

- Flow Pattern

- Axial and radial

- Efficiency

- Effective mixing at low speed

- Construction Material

- Stainless steel 1.4301, 1.4404, 1.4571

- Design Type

- 2-fold or 3-fold spiral design

- Standard Diameter

- Up to 2, 000 mm

- Custom Sizes

- Available upon request

- Additional Coatings

- Available upon customer requirement

- CIP System

- Integrated

- Energy Requirement

- Low energy requirement

- Durability

- Low wear

- Working mechanism

- Spiral design for self-dynamic mixing

- Mixing movement

- Axial and radial flow

- Viscosity range

- Up to 100, 000 mPas

- Material incorporation

- Fast incorporation of solids

- Flow pattern

- Laminar and turbulent

- Batch vs. continuous operation

- Batch

- Cleaning method

- CIP

- Energy efficiency

- Low energy demand

- Automation level

- Compatible with VISCO JET solutions

- Corrosive resistance (e.g. acids)

- Yes

- Cleanability

- Easy to clean with CIP systems

- Density/particle size

- Suitable for high-viscosity and solid suspension

- Chemical resistance

- Stainless steel 1.4301, 1.4404, 1.4571

- Custom material options

- Superduplex, Hastelloy

- Design Type

- 2-fach, 3-fach Ausführung

- Maximum Diameter

- Up to 2, 000 mm

- Material

- Stainless Steel 1.4301, 1.4404, 1.4571

- Optional Configurations

- Gap-free welded, Tornado version for IBC

- Tank Compatibility

- Horizontal and Vertical Tanks

- Integration Options

- CIP Systems

- Material

- Edelstahl 1.4301, 1.4404, 1.4571

- Rührorgandurchmesser

- Standard bis zu 2.000 mm

- Ausführung

- 2-fach oder 3-fach Rührorgankonen

- Optionale Lösungen

- Spaltfrei verschweißt, Tornado Version für IBC Container

- Einbauoptionen

- Kombination mit mehreren Rührebenen und Restmengenrührer

- Individuelles Material

- Je nach Kundenanforderung, z.B. Superduplex oder Hastelloy

- Individuelle Beschichtungen

- Nach Kundenanforderung