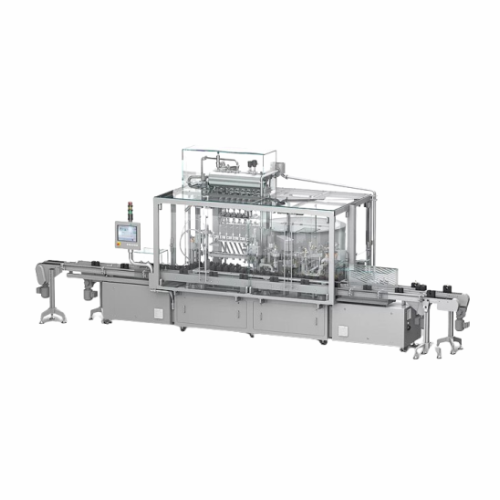

Automatic perfume filling line for cosmetic production

Ensure efficient and precise filling of perfume bottles and liquid cosmetics with this high-speed solution, offering flexibility and adaptability for both small and large-scale production needs.

Fills, Caps, and Crimps Liquid Cosmetics

The fragrance 50 by groninger is an automatic perfume filling machine designed specifically to streamline the production of liquid cosmetics such as perfumes, aftershaves, and eau de toilette. This machine stands out for its high-speed capability, processing up to 50 bottles per minute, ensuring optimal productivity while maintaining precision in filling and capping operations. It features a crimping station with integrated quality control and supports flexible format changes, allowing it to handle diverse product designs and closure types without compromise.

Ideal for cosmetic manufacturers and perfume producers, the fragrance 50 integrates seamlessly into your production line, thanks to its comprehensive processes including filling, capping, crimping, testing, transporting, and labeling. Its compact design requires minimal space, yet it offers maximum accessibility for maintenance and cleaning, with a fully CIP capable system to prevent contamination and reduce downtime.

The machine also features a walking beam transport system for efficient handling of glass or plastic bottles, with a format-independent capability that accommodates unusual bottle designs and closure options—either crimp or screw. Furthermore, its automated operation is controlled via integrated control cabinets, supporting continuous and high-speed production while minimizing product loss through precise filling level regulation.

groninger’s fragrance 50 is built for reliability and efficiency, making it a modern solution that adapts to evolving production needs, supported by customization options and engineering support to ensure the equipment aligns perfectly with your operational requirements.

Benefits

- Increases production efficiency by processing up to 50 bottles per minute.

- Ensures product quality with integrated quality control during crimping.

- Offers versatile applications with flexible format changes for different bottle designs.

- Minimizes product loss with precise filling level regulation.

- Reduces maintenance time with easy cleaning and fully CIP capable system.

- Applications

- Perfumes, Liquid cosmetics, Eau de toilette, Aftershave

- End products

- Aftershave lotions, Perfume bottles, Eau de toilette sprays, Essential oil blends, Facial mists

- Steps before

- Purification, Batch preparation, Container inspection, Spray pump assembly

- Steps after

- Labeling, Capping, Packaging, Quality control inspection

- Input ingredients

- perfume, aftershave, eau de toilette, spray pumps, dip tubes

- Output ingredients

- filled perfume bottles, filled aftershave bottles, filled eau de toilette bottles, crimped closures, screw closures

- Market info

- Groninger is known for its expertise in manufacturing high-quality filling and packaging machinery for the pharmaceutical, cosmetics, and consumer healthcare industries, with a strong reputation for innovation, precision engineering, and customer-focused solutions.

- Speed

- Up to 50 bottles per minute

- Capacity

- Handles small and large production batches

- Filling Method

- Volumetric / gravity

- Filling Accuracy

- High process reliability with precise filling process control

- Automation

- Automatic

- Filling Volume

- Adjustable for various bottle sizes

- Crimping Station

- Integrated quality control

- Walking Beam Transport

- For glass or plastic objects

- Filling Level Regulation

- Ensures consistent filling level

- Closure Options

- Crimp or screw closures

- Compact Design

- Little space requirement

- Relocation Capability

- Easy to relocate

- CIP Capability

- Fully CIP capable

- Flexibility

- Expandable and modifiable

- Working mechanism

- Automatic, high-speed, flexible

- Integrated steps

- Filling, capping, labeling

- CIP/SIP

- Fully CIP capable

- Batch vs. continuous operation

- Batch

- Automation level

- Fully automated systems

- Changeover time

- Quick changeover capabilities

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Viscosity

- Thick creams / Light liquids

- Container type

- Glass / Plastic

- Container size

- Various bottle sizes

- Closure type

- Crimp / Screw

- Filling purpose

- Perfume / Aftershave / Eau de toilette

- Foaming

- Low risk

- Heat sensitivity

- Non-sensitive

- Compact footprint

- Yes

- Control panel type

- Integrated control cabinets

- Discharge method

- Walking beam transport with changeable transport puck

- Flexibility

- Expandable and modifiable configuration

- Machine type

- Automatic perfume filling machine

- Crimping station

- Integrated quality control

- Filling speed

- Up to 50 bottles per minute

- Filling method

- Automated or manual options

- Closure type

- Crimp or screw closures

- Expansion flexibility

- Expandable and modifiable

- Format handling

- Walking beam transport with changeable transport puck

- Filling volume regulation

- Filling level regulation

- Integration

- Labeling and robotic solutions

- Control cabinets

- Integrated control cabinets