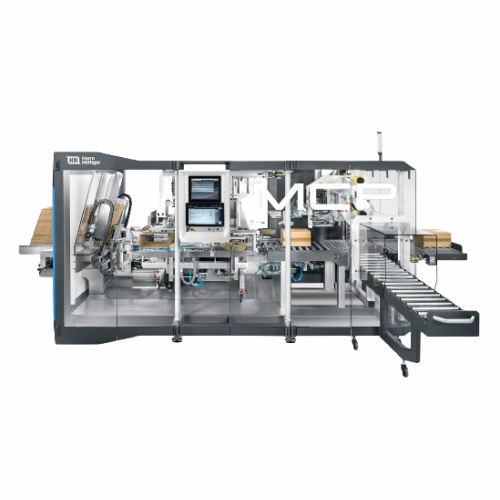

End-of-line casepacker for shipping boxes

Streamline your packaging line efficiency with this versatile casepacker, designed for seamless integration of folding box handling, stacking, and sealing processes, ensuring consistent and reliable end-of-line operations.

Packs and Stacks Pharmaceutical and Medical Packaging

The MCP Casepacker from Harro Höfliger is an advanced end-of-line solution designed for pharmaceutical and medical device manufacturers. It excels in efficiently packing, stacking, and grouping a wide range of products including diagnostic test kits, pre-filled syringes, and blister packs, into secure shipping boxes. Operating on an intermittent basis, it offers automated logistics and seamless integration with upstream processes like cartoning and dosing, ensuring high throughput rates of up to 10 boxes per minute. This versatile machine supports various packaging methods, utilizing robot-assisted technology for precise feeding and handling. It offers serialized packaging for improved product tracking and anti-counterfeiting measures, meeting stringent GMP and FDA compliance requirements. Engineered with a compact footprint and rapid changeover capabilities, the MCP Casepacker is available in durable materials suited for the high hygienic standards demanded by pharmaceutical applications, ensuring easy cleaning and maintenance. Custom engineering support is available to tailor the system precisely to your production needs.

Benefits

- Enhances packaging efficiency by seamlessly integrating into existing high-speed production lines.

- Reduces operational costs through automated packing and stacking processes.

- Increases product security and traceability with built-in serializing capabilities.

- Provides flexibility with rapid size changes and a wide range of packaging formats.

- Complies with GMP and FDA standards, ensuring high hygiene and safety in pharmaceutical applications.

- Applications

- Aseptic processes, Continence care, Inhalation products, Transdermal, Skin care, Wound, Microneedles, Ostomy, Packaging, Surgical sutures, Oral delivery systems, Medical, Pharmaceutical device assembly, Diagnostic products, Capsule filling, Portion packs, Eye care

- End products

- Insulin pen needles, Effervescent tablets, Unit-dose sachets, Hydrocolloid dressings, Nicotine patches, Diagnostic test kits, Blister packs, Pre-filled syringes, Adult diapers, Ostomy bags, Catgut sutures, Metered-dose inhalers, Auto-injectors, Contact lens solution packaging

- Steps before

- Folding box feeding, Grouping, Automated stacking, Cartoning products

- Steps after

- Shipping, Labeling, Quality inspection, Sealing

- Input ingredients

- folding boxes, product components

- Output ingredients

- packed shipping boxes, final packaged folding boxes, labeled shipping boxes

- Market info

- Harro Hoefliger is known for its expertise in manufacturing custom, engineered-to-order packaging and production equipment, particularly for the pharmaceutical, healthcare, consumer goods, and chemical industries, with a reputation for precision, innovation, and quality engineering solutions.

- Output

- up to 10 boxes/min

- Automation

- Automated stacking and packaging

- Loading Method

- Side loading / Wrap-around

- Footprint

- Extremely small

- Size Change

- Rapid size changes with reproducible settings

- Packaging Formats

- Large range

- Control System

- Touch panels

- Working mechanism

- Side loading / Wrap-around

- Integrated steps

- Feeding, grouping, stacking, packing

- Changeover time

- Rapid size changes with reproducible settings

- Automation level

- Automated logistics with robot technology

- Batch vs. continuous operation

- Intermittent

- Energy efficiency

- Extremely small footprint

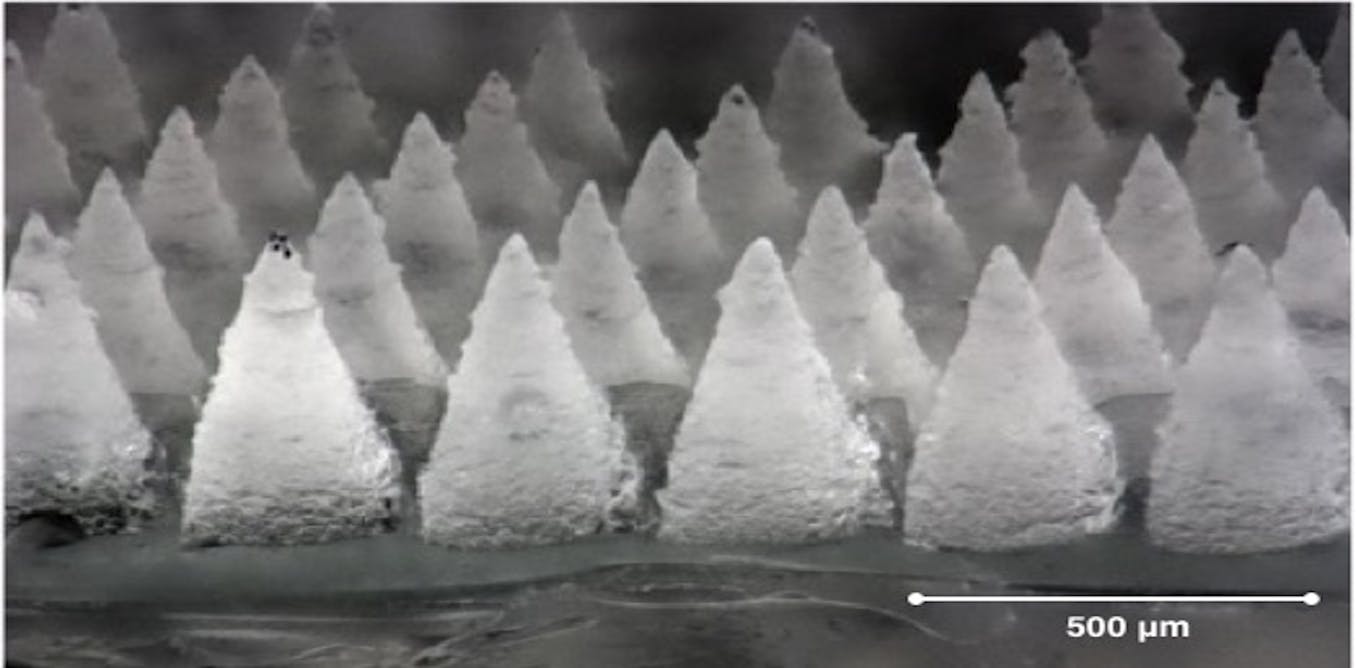

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Control panel type

- Touch panel

- Compact footprint

- Extremely small

- Machine footprint

- Single track layout

- Discharge method

- Side loading / Wrap-around

- Size change flexibility

- Rapid and reproducible

- Packaging format range

- Large

- Control panel type

- Touch panel

- Footprint

- Extremely small

- Packaging format range

- Large range of formats

- Integration possibilities

- With MKT cartoning machine

- Loading method

- Side loading / Wrap-around