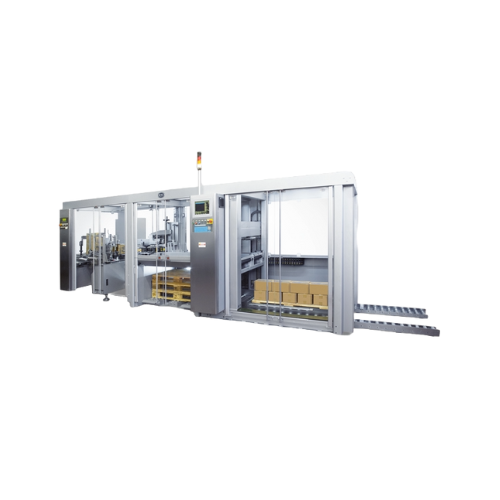

Integrated case-packing and case-palletizing system

Streamline your production line with an all-in-one system that seamlessly integrates case packing and palletizing, optimizing space and enhancing efficiency with a compact design and rapid change-overs.

Packs and Palletizes Solid Products Efficiently

The SPZ from Tecnicam is an engineered-to-order integrated case-packing and palletizing monobloc designed specifically for the pharmaceutical, cosmetic, and food sectors. This compact machine combines the proven reliability of case packers and palletizers into a seamless operational unit. Its cantilevered case packing module ensures clean separation between mechanical and operational functions, enhancing accessibility and maintenance efficiency. The SPZ leverages a CAM patented Mechanical Memory® system for rapid, precise size change-overs, adapting effortlessly to varying product dimensions and pallet configurations.

The machine excels in handling blister packs, cream tubes, bottled vitamins, boxed perfumes, packaged snack bars, and other solid goods. It performs multiple functions such as case forming, stacking, filling, and closing, with options for self-adhesive tape, moistening paper, or hot-melt glue closures. Additionally, it integrates seamlessly with existing lines, offering optional equipment for case coding, label application, checkweighing, and barcode reading. A built-in buffer allows for uninterrupted operation during palletizer stoppages.

Enhanced with CNC-controlled linear interpolation for smooth motion dynamics, the SPZ ensures prolonged machinery lifespan and operational stability. Supporting automated pallet handling, the system can include slip-proofing and reject mechanisms for defective products, optimizing productivity and efficiency in high-speed, continuous operations. Adaptable and robust, the SPZ is constructed with materials resistant to wear and corrosion, compliant with industry standards, and supports easy cleaning and maintenance through its accessible design and optional CIP systems.

Benefits

- Optimizes space and reduces footprint by integrating packing and palletizing into a single monobloc.

- Enhances operational efficiency through rapid size change-overs with Mechanical Memory®, minimizing downtime.

- Increases throughput capacity with continuous high-speed operation, suitable for demanding production environments.

- Supports precise product handling and safety with seamless integration of checkweighing and barcode reading.

- Minimizes maintenance intervals with robust construction and easy-access design for efficient cleaning and upkeep.

- Applications

- Food products, Cosmetics, Pharmaceuticals

- End products

- Palletized cereal boxes, Sealed boxes of cosmetics, Boxed perfume, Packaged dry pasta, Shrink-wrapped chocolate boxes, Cream tubes, Packaged snack bars, Blister packs of pills, Bottled vitamins, Cartons of meal kits

- Steps before

- Product Sorting, Product Stacking, Product Filling

- Steps after

- Palletizing, Case Weighing, Labeling, Barcode Reading

- Input ingredients

- empty cases, products for packing, layer pads

- Output ingredients

- packed cases, palletized loads, full pallets

- Market info

- CAM Packaging is known for its expertise in designing and manufacturing advanced packaging machinery tailored to client specifications, with a strong reputation for reliability and innovation in the engineered-to-order equipment market.

- Case closure method

- Self-adhesive tape, moistening-type paper, hot-melt glue

- Case pick-off system

- Gripper or suction cup systems

- Size change-over system

- Mechanical Memory®

- Automation

- CNC with linear interpolation of the axes

- Palletizing modes configuration

- Automatic

- Checkweighing capability

- Yes

- Optional equipment

- Taping system, case coding system, label application system

- Recommended industries

- Pharmaceutical, Cosmetic, Food

- Changeover time

- Easy and fast

- Batch vs. continuous operation

- Automatic

- Automation level

- PLC / CNC

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Product type compatibility

- Pharmaceutical, Cosmetic, Food

- Machine footprint

- Compact layout

- Feed/discharge method

- Gripper or suction cup systems

- Control panel type

- Operator’s side access

- Size change-over method

- CAM Mechanical Memory® system

- Case closure method

- Self-adhesive tape / Paper / Hot-melt glue

- Size change-over

- Mechanical Memory® System

- Product handling system

- Gripper / Suction cup

- Additional equipment

- Taping system / Case coding system / Label application system / Printers

- Palletizing mode configuration

- Automatic

- Optional appliances

- Automatic pallet feeder / Layer pad feeder / Slip-proof glue unit