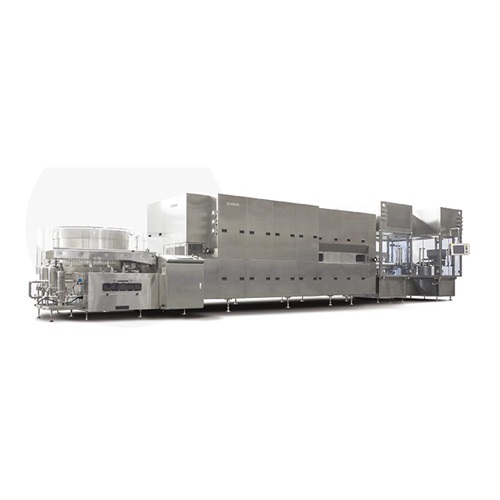

Vial washing drying filling sealing line for pharmaceutical production

Streamline your vial production with this integrated solution, combining washing, drying, sterilizing, filling, stoppering, and capping for high-speed, continuous processing of liquid and freeze-dried products.

Processes Vials: Washing to Capping

The KQCL, MRSJ, KGS, and KZG series from Shinva deliver a comprehensive solution for vial processing in pharmaceutical, biotech, and cosmetic industries. This system specializes in washing, sterilizing, filling, stoppering, and capping vials, facilitating efficiency while adhering to GMP standards.

Designed for high-speed, continuous operation, the line incorporates a vertical ultrasonic bottle washing machine and a tunnel-type sterilization oven, providing precise cleaning and sterilization suitable for liquid and freeze-dried products. The vial filling machine and capping unit utilize modular design and full servo driving force for seamless integration and stability in production lines.

Applications range from injectables to freeze-dried powders, with typical end products including vials for vaccines, hormones, and cosmetics. With a focus on energy efficiency, the equipment minimizes cross-contamination risks through independent wash needles, while the sterilization oven’s data monitoring supports thorough compliance.

Equipped with user-friendly automation features and a design supporting clean-in-place (CIP) systems, maintenance is streamlined to ensure continuous operation. Optional customization and engineering support are available, ensuring the equipment meets specific production demands.

Benefits

- Enhances operational efficiency with high-speed continuous processing.

- Ensures product safety and quality through compliance with GMP standards.

- Minimizes contamination risk with independent wash needles.

- Streamlines maintenance with integrated CIP system.

- Offers flexibility for various vial types and product forms with modular design.

- Applications

- Animal pharmaceutical factory, Cosmetic products, Health products, Freeze-dried powder products, Biopharmaceuticals, Liquid injection products, Pharmaceuticals

- End products

- Cosmetic skin treatment vials, Animal health solution vials, Vials of liquid injections, Freeze-dried vaccine vials, Hormonal injection vials, Vitamin injection ampoules, Antibiotic powder vials, Cosmetic serum vials, Nutritional supplement vials, Homeopathic liquid vials

- Steps before

- Container Preparation, Component Staging

- Steps after

- Quality Control, Packaging and Labeling, Distribution

- Input ingredients

- vials, freeze-dried powder, liquid injection products, WFI (Water for Injection)

- Output ingredients

- washed vials, dried and sterilized vials, filled vials, stoppered vials, capped vials

- Market info

- Shinva is known for manufacturing medical equipment, including sterilization and disinfection devices, radiotherapy products, and diagnostic imaging systems, demonstrating expertise in healthcare solutions and a strong reputation for quality in the medical industry.

- Washing method

- Ultrasonic rough wash, Needle WFI wash

- Sterilization type

- Hot Air Circulating Tunnel

- Filling method

- Modulary combination and full servo driving force

- Capping method

- Single-knife multi-head

- Compliance

- GMP Requirements

- Data monitoring

- Monitor and record working data

- Contamination control

- Non-contact wash, independent needles

- Automation

- Automated filling and capping process

- Cycle stages

- 20+ procedures can be completed

- Machine type

- Vertical ultrasonic bottle washing, tunnel type sterilization oven, vial filling and stoppering, vial capping

- Working Mechanism

- Ultrasonic wash, hot air sterilization, filling, stoppering, capping

- Integrated Steps

- Washing, drying, sterilizing, filling, stoppering, capping

- Automation Level

- Fully automated with modular combination

- CIP/SIP

- Not explicitly stated, but implied in washing and sterilization stages

- Changeover Time

- Not explicitly stated

- Batch vs. Continuous Operation

- Batch operation with independent machine use option

- Cleaning Method

- Ultrasonic cleaning, Water and air sweeping

- Container size

- Variety of vial sizes

- Container type

- Glass vials

- Product type

- Freeze-dried powder and liquid injection

- Bottle washing method

- Ultrasonic and needle WFI wash

- Sterilization oven type

- Tunnel type

- Filling and stoppering module

- Modular combination

- Capping method

- Single-knife multi-head

- Bottle conveying method

- Turntable

- Control panel type

- HMI/PLC

- Integration possibilities

- Modular components integration

- Compact design

- Yes

- Automation level

- Full servo driving force

- Material compatibility

- Stainless steel components