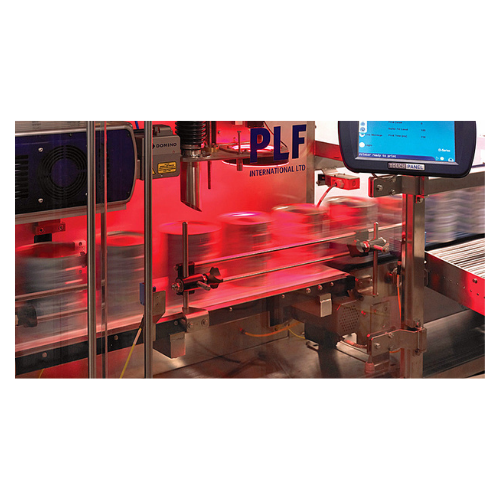

Laser date and batch coder for product identification

Ensure precise product traceability and enhance packaging quality with high-speed laser date and batch coding, ideal for maintaining compliance and optimizing efficiency across diverse packaging types.

Codes and Inspects Packaging for Traceability

The Laser Date and Batch Coding System from PLF International offers a precise, maintenance-free solution for coding across various packaging types, enhancing traceability and compliance in food, beverage, and pharmaceutical industries. It eliminates ink usage by utilizing laser technology, ensuring clean and uninterrupted operations. Designed for high-speed environments, it efficiently codes up to 300 containers per minute, accommodating diverse materials including glass, composite, and metal. Integration is streamlined with vision inspection systems for code verification, minimizing errors and ensuring accuracy. The system supports unlimited lines of text in multiple languages and can produce both graphics and 2D datamatrix codes, suitable for international markets. It’s capable of seamless integration into existing lines, with optional Ethernet protocols for remote connectivity and automatic position setting for quick changeover between different container types. This facility supports continuous, 24/7 operation, ideal for demanding production schedules. With no consumables or lubrication required, the system offers low maintenance and operational efficiency, making it a reliable investment for sustainable and hygienic coding solutions.

Benefits

- Enhances product traceability and compliance with precise laser coding.

- Minimizes operational costs by eliminating ink and consumable needs.

- Boosts efficiency with speeds up to 300 containers per minute.

- Lowers maintenance demands due to its lubrication-free design.

- Ensures reliability with vision inspection for accurate code verification.

- Applications

- Product traceability, Beverage packaging, Composite packaging, Food packaging, Glass containers, Pharmaceutical packaging, Pet food packaging, Canned goods, Dairy products packaging

- End products

- Pill bottles, Canned beans, Traceable food products, Composite juice containers, Milk cartons, Cereal boxes, Beverage cartons, Pet treat bags, Glass bottles

- Steps before

- Filling, Preparation, Fresh Produce Processing

- Steps after

- Packing, Sterilization, Labeling

- Input ingredients

- cans, composite containers, glass containers, individual packs, outer completed cases

- Output ingredients

- product identification codes, batch numbers, date codes, traceability codes

- Market info

- JBT is known for manufacturing innovative industrial machinery and solutions, particularly in the food processing and air transportation sectors, renowned for their advanced technology, reliability, and customer-focused engineered-to-order solutions tailored to specific industry needs.

- Speed

- Up to 300 cpm

- Text orientation

- Unlimited lines in any orientation

- Font range

- Range of fonts and sizes

- Automation

- Automatic position setting for container changeover

- Code type compatibility

- Graphics and 2D datamatrix codes

- Automation level

- PLC / Manual / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- Changeover time

- Automatic position setting

- Cleaning method

- Air filtration for hygienic operation

- CIP/SIP

- CIP 121°C

- Container type compatibility

- Cans, composite, glass

- Cleanability

- Air filtration for hygienic operation

- Corrosive resistance

- No ink usage (cleaner operation)

- Container type

- Cans, composite, glass

- Control panel type

- Touchscreen / HMI

- Integration possibilities

- Embedded Ethernet

- Automatic position setting

- Yes