Vacuum paddle dryer for chemical and pharmaceutical applications

Achieve precise moisture control and efficient drying in critical processes with this vacuum paddle dryer, designed to enhance product quality in mixing, drying, and granulation while ensuring gentle handling of sensitive materials.

Performs Mixing, Drying, Granulation, and Cooling

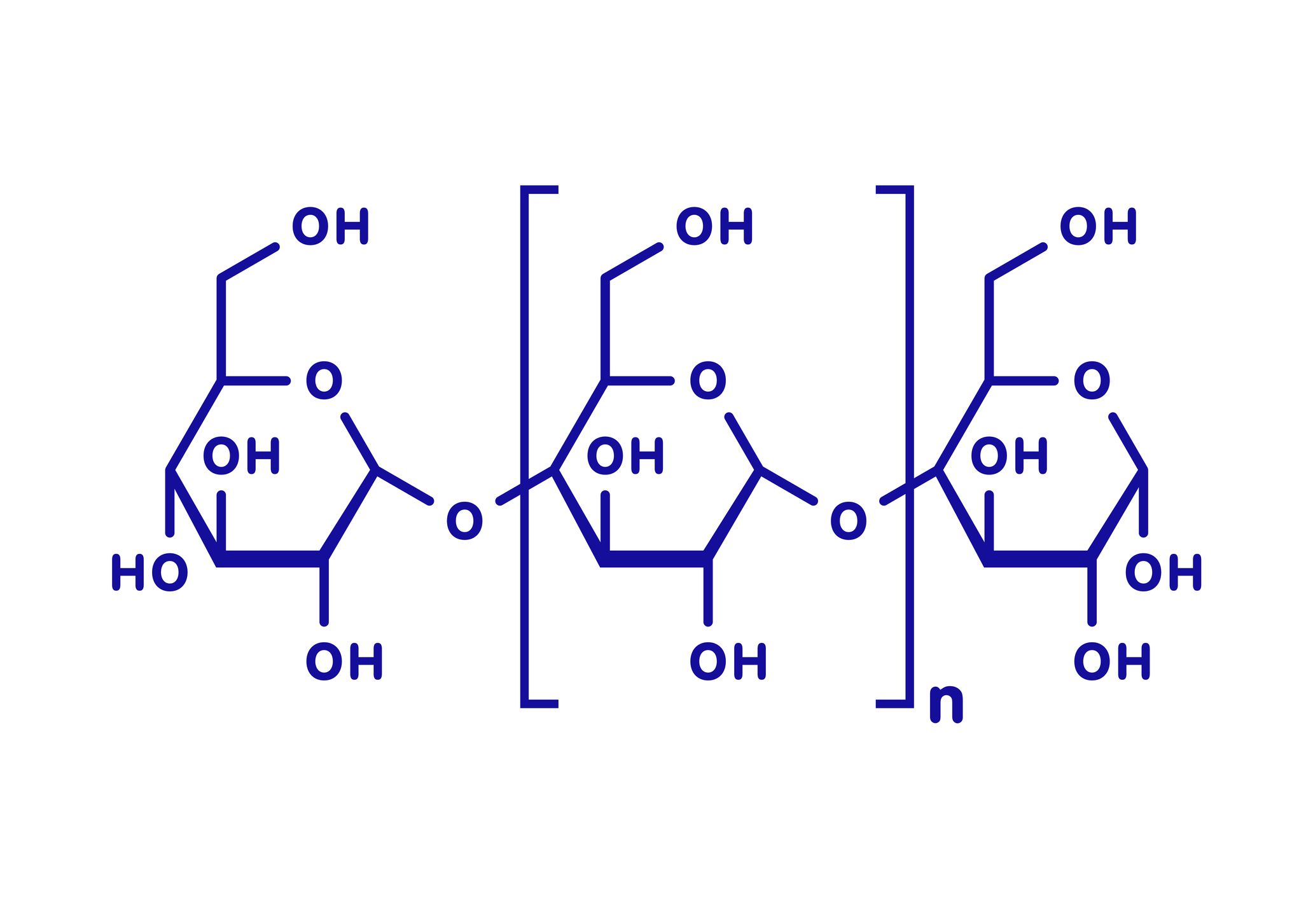

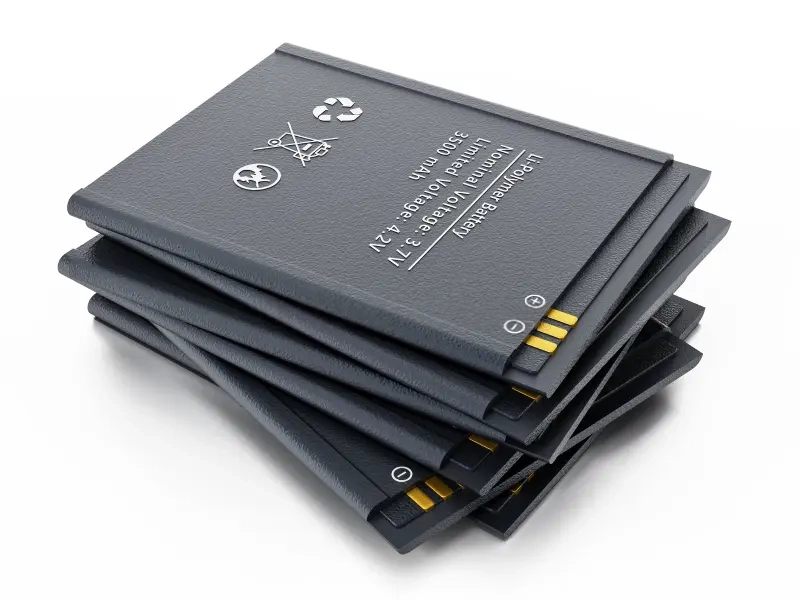

The DRUVATHERM® Vacuum Shovel Dryer from Gebrüder Lödige Maschinenbau GmbH is a versatile batch vacuum dryer designed for industries like pharmaceuticals, chemicals, and plastics. It uniquely combines intensive mixing and drying in one unit by employing frequency-controlled shovel agitators achieving an optimal product flow, thus enhancing heat transfer and reducing drying times. Applications range from pharmaceutical granules, personal care creams, and polyethylene pellets to starch derivatives and battery components. It supports multi-phase processes including mixing, drying, granulation, and cooling, efficiently handling solids, powders, and slurries. The unit’s pneumatic purging system ensures particle control, assisting in solvent recovery with minimized energy consumption. Built for durability, it is made with high-grade materials suitable for corrosive substances, meeting stringent industry standards. Easily integrated into existing lines, the system is PLC-controlled and offers flexible customization options, making it an indispensable solution for sophisticated production requirements.

Benefits

- Enhances processing efficiency with rapid drying times and reduced energy consumption.

- Improves product quality through uniform heat distribution and gentle handling.

- Facilitates flexibility in production with multi-phase capabilities in a single unit.

- Lowers operational costs by optimizing solvent recovery during drying.

- Ensures compliance with industry standards for safety and quality assurance.

- Applications

- Chemicals, Food, Polysaccharides, Cosmetics, Plastics, Batteries, Pharmaceuticals

- End products

- Polyethylene pellets, Personal care creams, Dried food powders, Starch derivatives, Lithium-ion battery cathode materials, Pharmaceutical granules

- Steps before

- Mixing, Granulation

- Steps after

- Cooling, Solvent Recovery

- Input ingredients

- chemicals, cosmetic ingredients, plastic raw materials, food ingredients, pharmaceutical ingredients, polysaccharides, battery materials

- Output ingredients

- dried chemicals, cosmetic products, processed plastics, processed food products, pharmaceutical granules, dried polysaccharides, battery components

- Market info

- Loedige Process Technology is renowned for its expertise in industrial mixing, granulation, drying, and coating technologies, offering engineered-to-order solutions for various industries, including pharmaceuticals, chemicals, and food processing.

- Mixing type

- Vacuum Shovel Dryer

- Mixing intensity

- Intense mixing with a three-dimensional product movement

- Drying method

- Batch vacuum drying

- Heat transfer

- Maximum heat transfer coefficients

- Product treatment

- Gentle thermal treatment in vacuum mode

- Process phases

- Mixing, granulation, drying, cooling

- Solvent recovery

- Cost-efficient

- Drying speed

- Incredibly short drying times due to mechanically generated fluid bed

- Temperature control

- Temperature control jacket

- Particle contact frequency

- Frequent due to heat exchange surface

- Product movement

- Intelligent product movement for intense contact

- Chopper option

- Rotating choppers for breaking down agglomerated product

- Filtration system

- Pneumatically purged filter

- Mixing elements

- Frequency-controlled

- Working mechanism

- Vacuum paddle drying

- Batch vs. continuous operation

- Batch

- Integrated steps

- Mixing, granulation, drying, cooling

- Temperature control

- Heat transfer coefficients

- Solvent recovery

- Cost-efficient

- Product movement

- Three-dimensional fluid bed

- Cleaning method

- Pneumatically purged filter system

- Automation level

- Frequency-controlled mixing elements

- Gentle thermal treatment

- Yes

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Agglomeration risk

- Optionally available rotating choppers

- Drum size

- 10–300 L

- Control panel type

- Frequency-controlled

- Integration possibilities

- Integration with existing systems for batch or continuous operations

- Temperature control

- Temperature control jacket

- Heat exchange surface

- Optimized for short drying times

- Product movement

- Three-dimensional product movement