Industrial high pressure homogenizer for dairy and pharmaceutical

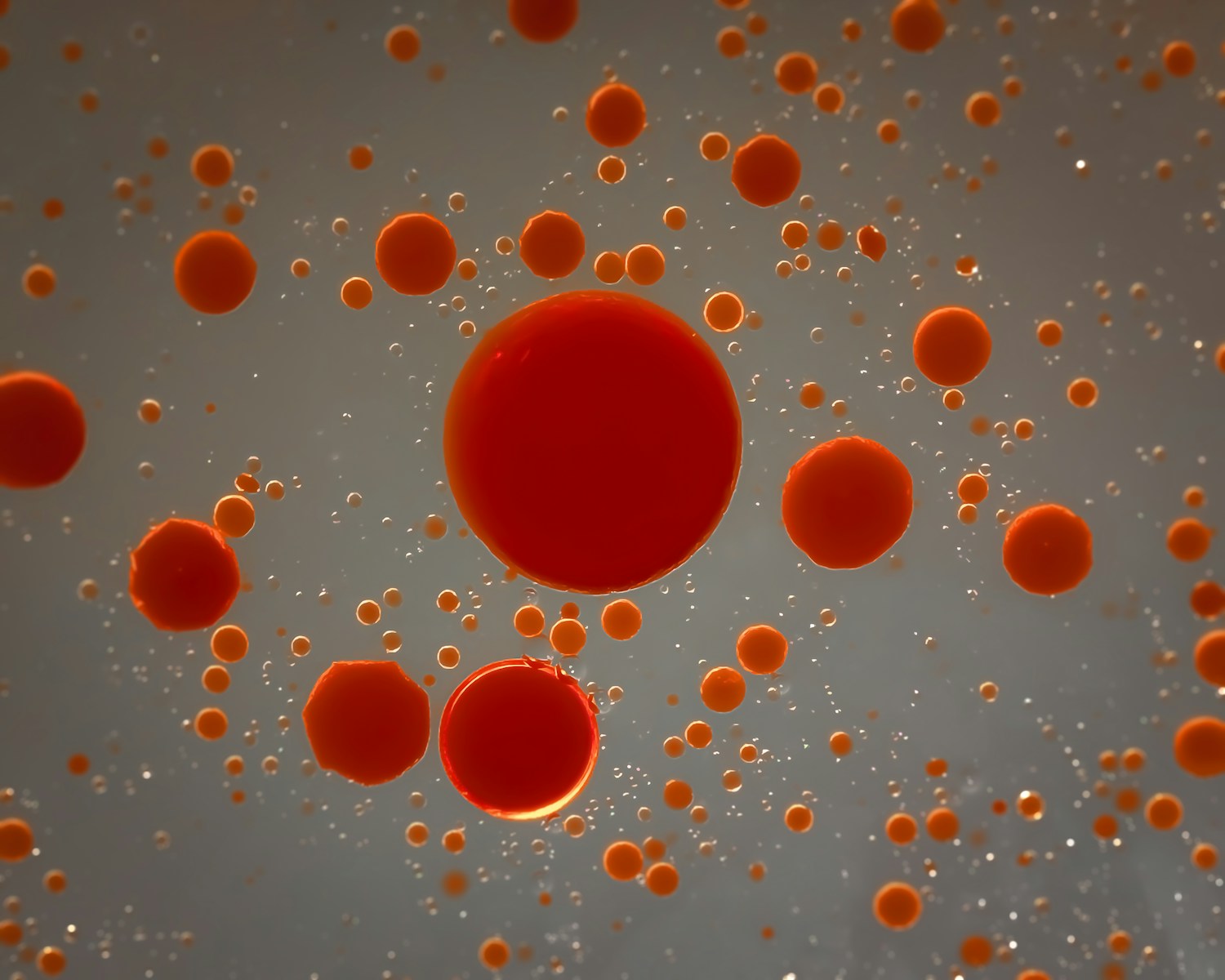

Achieve consistent texture and stability in products with a high-pressure homogenizer designed to optimize emulsification and particle distribution—ideal for enhancing product quality in continuous production.

Ensures Homogenization of Liquids in High-Pressure Conditions

The APV Rannie 5 and Gaulin 5 Series homogenizers are engineered by industry leaders in high-pressure homogenization. These robust systems are designed for challenging production environments, delivering consistent particle size reduction and emulsion stability across diverse applications, such as dairy milk homogenization, yogurt production, and pharmaceutical suspensions. Equipped with a 3-plunger design and customizable valve housings, these homogenizers offer a variety of material options to ensure compatibility with your specific processing needs. With capacities tailored to various scales of operation, they are PLC-controlled for seamless integration into automated lines with remote monitoring capabilities. Featuring an environmentally friendly design, the series is also engineered for low maintenance costs, incorporating easy-to-clean systems that support Clean-In-Place (CIP) operations. Suitable for continuous use in environments demanding consistent high-pressure processing, they meet industry standards for safety and performance, making them ideal for processors in the dairy, food, cosmetic, chemical, pharmaceutical, and biotech sectors.

Benefits

- Ensures consistent product quality with precise particle size reduction for superior end-product stability.

- Minimizes operational disruptions with low-maintenance and service-friendly design.

- Reduces environmental impact through energy-efficient operation and eco-friendly design features.

- Seamlessly integrates into existing processing lines with customizable configurations and remote monitoring.

- Complies with industry safety and quality standards, ensuring reliable performance across multiple sectors.

- Applications

- Cosmetic products, Chemical products, Biotech products, Pharmaceutical products, Food products, Dairy products

- End products

- Cosmetic creams, Pharmaceutical suspensions, Biotech recombinant proteins, Milk homogenization, Yogurt production, Chemical emulsions

- Steps before

- Mixing, Blending, Emulsification

- Steps after

- Sterilization, Packaging, Filling

- Input ingredients

- milk, cream, fruits, cosmetic ingredients, chemical ingredients, pharmaceutical ingredients, biotech products, plant-based ingredients, oil, water, personal care ingredients

- Output ingredients

- homogenized milk, homogenized cream, fruit juice, smooth cosmetics, blended chemical solutions, processed pharmaceuticals, refined biotech products, homogenized plant-based drinks, emulsified oils, purified water, personal care products

- Market info

- SPX Flow is renowned for its expertise in manufacturing industrial ETO equipment, specializing in fluid handling and processing solutions. They are recognized for innovation, reliability, and providing efficient solutions across diverse industries, including food, beverage, and industrial markets.

- Plunger Type

- 3-plunger

- Valve Housing Type

- Mono-Block / Three-Piece

- Material Selection

- Custom-selected for application

- Service Requirements

- Low maintenance

- Working mechanism

- 3-plunger system

- Valve housing type

- Mono-Block / Three-Piece

- Material selection customization

- Plungers, packings, valves, seats, seals

- Customization options

- Standard and special options available

- Maintenance

- Low maintenance costs

- User-friendliness

- Easy to operate

- Environmental impact

- Environmentally friendly design

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Valves

- Mono-Block / Three-Piece

- Plunger material

- Custom-selected

- Valve housing material

- Custom-selected

- Control panel type

- HMI / PLC

- Valve housing

- Mono-Block / Three-Piece

- Plunger materials

- Custom-selected

- Packing materials

- Custom-selected

- Pump valve materials

- Custom-selected

- Valve seat materials

- Custom-selected

- Seal materials

- Custom-selected

- Integration possibilities

- Standard and special options available