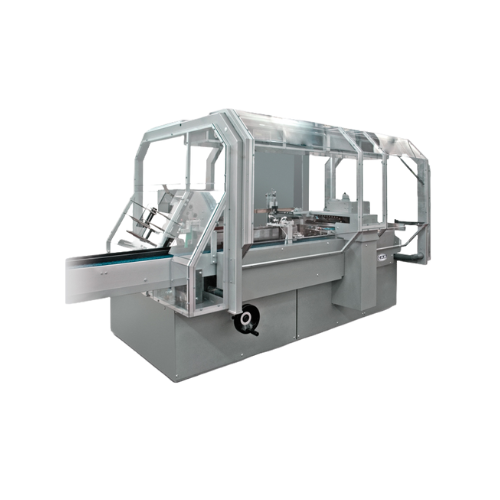

Tray forming machine for packaging solutions

Streamline your packaging operations with precision-engineered tray forming technology, designed to handle diverse formats from food to medical equipment, ensuring consistent quality and high-speed production for your packaging needs.

Forms and Packs Trays at High Speed

The NCX Tray Forming Machine from Tecnicam is an automatic solution designed to enhance production efficiency for packaging and manufacturing facilities. Specializing in high-speed tray forming, this machine is perfect for producing a variety of products such as egg cartons, medical equipment trays, and bakery containers. Its robust design supports seamless integration into existing production lines, allowing for automated tray forming and packing without interruption.

The NCX operates with precision, achieving consistent throughput across multiple shifts. It is capable of handling diverse materials, ensuring durability for applications in the food, pharmaceutical, and industrial sectors. The machine is engineered for energy efficiency, with optimized motor controls that reduce consumption by 15%.

Built with stainless steel components, the NCX is suited for environments requiring strict hygiene standards. It meets relevant industry regulations and is easily cleaned through an integrated cleaning system, minimizing downtime. With PLC controls, the NCX offers remote monitoring and diagnostics, ensuring reliable operation with minimal supervision. Customization options are available to tailor the machine’s parameters to your specific production requirements, supported by Tecnicam’s engineering expertise.

Benefits

- Increases production efficiency with high-speed tray forming capabilities.

- Lowers energy costs through optimized motor control, saving 15% on energy usage.

- Ensures product quality with consistent and precise tray forming.

- Simplifies maintenance with easy-to-clean stainless steel design.

- Facilitates seamless integration into existing production lines with automated operations.

- Applications

- Consumer goods, Industrial products, Trays, Packaging, Food packaging, Retail products

- End products

- Egg cartons, Fruit packaging trays, Sandwich containers, Bakery item containers, Chocolate boxes, Medical equipment trays, Blister pack trays, Seedling trays, Packaging for electronics, Fast food packaging trays

- Steps before

- Molding, Material Preparation, Cutting

- Steps after

- Packing, Labeling, Quality Inspection

- Input ingredients

- tray blanks, flat cardboard sheets

- Output ingredients

- formed trays, assembled trays

- Market info

- CAM Packaging is known for its expertise in designing and manufacturing advanced packaging machinery tailored to client specifications, with a strong reputation for reliability and innovation in the engineered-to-order equipment market.

- Machine Type

- Tray forming machine

- Automation

- Automatic

- Operation

- Flowpack

- Working mechanism

- Tray forming

- Automation level

- Automatic

- Batch vs. continuous operation

- Batch

- Cleaning method

- Manual

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Tray type

- Formed trays