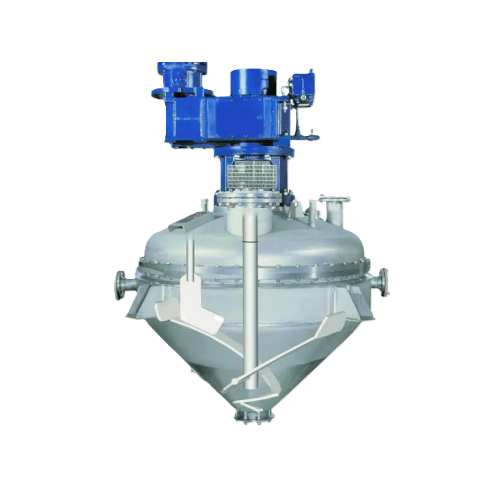

Vacuum dryer for free-flowing and pasty solids

Achieve precise drying and mixing with this vacuum dryer, optimizing heat transfer and minimizing shear to enhance product quality while reducing processing times for solid and pasty materials.

Dries and Mixes Industrial Solids Efficiently

The Vacuum Dryer – SOLIDMIX VST/VPT from EKATO is designed to meet the rigorous demands of industrial solid processing. This innovative equipment excels in efficiently drying and mixing solids, utilizing patented EKATO impeller technology for enhanced heat transfer and uniform product quality. A versatile solution, it serves diverse applications including fine chemicals, pharmaceuticals, and biopolymers, delivering controlled moisture removal crucial for end-products like active pharmaceutical ingredients and biodegradable polymers.

Operating on a batch process, the SOLIDMIX dryer offers volumes ranging from 50 to 32,000 liters, adaptable for both laboratory and production scales. Its design facilitates easy integration into existing production lines, boasting automation via a comprehensive PLC system that supports remote monitoring. Engineered for efficiency, it minimizes energy consumption with low-power input for maximum vertical mixing—an essential feature for reducing operational costs.

Constructed from corrosion-resistant materials and compliant with GMP standards, the SOLIDMIX VST/VPT ensures both durability and safety in processing. The inclusion of cleaning-in-place (CIP) systems facilitates efficient maintenance and contamination-free operations. Customizable elements such as adjustable impeller types, heating and cooling options, and adaptable system configurations ensure the equipment meets specific process requirements, backed by EKATO’s engineering support.

Benefits

- Enhances product quality with uniform heat distribution and gentle mixing.

- Reduces operational costs through energy-efficient impeller design.

- Facilitates easy integration with customizable configurations and automation.

- Minimizes contamination risk with effective cleaning-in-place systems.

- Complies with GMP standards for safe pharmaceutical and chemical processing.

- Applications

- Polymers, Biofuels, Biotechnology, Fine chemicals, Chemical intermediates, Biopolymers, Cosmetics, Foodstuffs, Minerals processing, Petrochemical, Chemical recycling of plastics, Apis, Pharmaceutical products, Plastics, Batteries

- End products

- Polyethylene terephthalate (pet) flakes, Active pharmaceutical ingredients, Chemical catalyst powders, Food flavoring concentrates, Esterified biofuel additives, Polypropylene powder, Lithium-ion battery components, Cosmetic cream bases, Biopolymer pellets, Synthetic fragrances, Recycled plastic granules, Biodegradable polymer granules, Vitamin e, Fine powder pigments, Mineral-filled polymer compounds, Calcium carbonate, Essential oils

- Steps before

- Mechanical separation, Filtration, Centrifugation

- Steps after

- Chemical reactions, Coating, Granulating, Cooling, Moistening

- Input ingredients

- solids, fine chemicals, pharmaceutical products, foodstuffs, pasty media, poorly flowing media

- Output ingredients

- free-flowing goods, bulk goods, dried solids, processed fine chemicals, dried pharmaceutical products, dried foodstuffs

- Market info

- Ekato is renowned for its expertise in mixing technology and process engineering, providing innovative and high-quality solutions for industrial mixing processes across various sectors, including chemical, pharmaceutical, and cosmetics industries.

- Capacity

- 50 L to 32, 000 L

- Automation

- PLC-controlled

- Heating and cooling system

- Integrated

- Vacuum system

- Yes

- Temperature measurement

- Integrated sensors

- CIP system

- Yes

- Impeller types

- ISOPAS, PARAVISC

- ATEX versions

- Zone 0 to Zone 2

- Impeller design

- Free-overhung shaft

- Solvent recovery system

- Included

- Contact material clearance

- Minimal wall clearance

- Homogeneous mixing

- Yes

- Batch size

- 50 L to 32, 000 L

- Drying operation

- Vertical mixing

- Moistening

- Available

- Working mechanism

- Vertical mixing with patented impellers

- Integrated steps

- Drying, mixing, chemical reactions

- Batch vs. continuous operation

- Batch

- CIP/SIP

- CIP cleaning system

- Automation level

- Automation system with process controls

- Energy efficiency

- Designed for minimum power input

- Gentle mixing

- Minimal shear for product protection

- Cleanability

- CIP systems

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Container Size

- 100 L to 32, 000 L

- Container Shape

- Vertical with conical bottom

- Agglomeration risk

- Chopper for breaking up agglomerates

- ATEX certification

- Zone 0 to Zone 2

- Effective volumes

- 50 L to 32, 000 L

- Height

- 2000 mm to 8500 mm

- Width

- 1000 mm to 5600 mm

- Weight

- 800 kg to 25000 kg

- Shape

- Vertical Conical Bottom

- Discharge method

- Optimized for Maximum Discharge

- Mixing impeller

- ISOPAS / SOLIDS-PARAVISC

- Vacuum system

- ASME, PED, or SELO compliant

- Control panel type

- PLC / HMI integration

- Impeller type

- ISOPAS / SOLIDS-PARAVISC

- System components

- Filter, CIP, Temperature measurement

- ATEX versions

- Zone 0 to Zone 2

- Agitator design

- Heatable agitator shaft

- Process technology solution

- Customizable