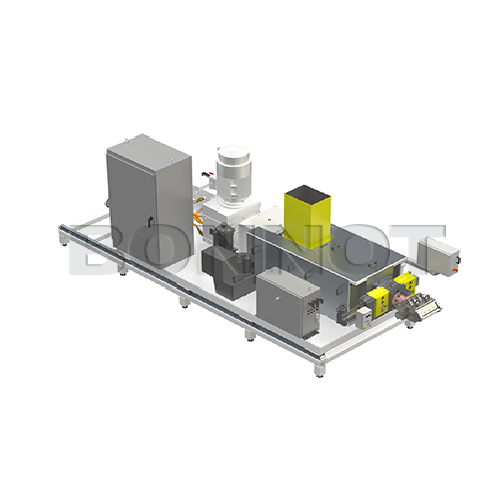

Custom extruder for specialized industrial applications

Experience unparalleled customization in extrusion technology, engineered to meet your unique production specifications and overcome the limitations of standard equipment.

Processes Diverse Materials into Custom Extrudates

From The Bonnot Company, the custom industrial extruder is engineered to meet the specific needs of diverse industrial applications, providing flexible solutions for intricate material processing. Specializing in tailored extruder configurations, this equipment features customizable screw geometries and die shapes, allowing precise formation of extrudates, ranging from pharmaceuticals to food products. Ideal for biopharmaceutical, fine chemical, and rubber product manufacturing, it efficiently integrates into existing production lines, enhancing workflow continuity and output quality. With options for temperature control and high-torque capacity, it addresses unique production challenges with ease. Built from durable materials to resist wear and corrosion, and designed for easy cleanability, the extruder supports quick changeovers for varied production needs. Backed by comprehensive customization and engineering support, The Bonnot Company ensures the extruder aligns perfectly with your operational requirements, from batch to continuous operations, while offering energy-efficient performance and seamless system integration.

Benefits

- Enhances production efficiency with customized configurations for diverse materials.

- Minimizes operational costs by accommodating high-torque and variable batch requirements.

- Ensures seamless integration with existing systems, reducing the need for extensive line modifications.

- Facilitates quick material changeovers, minimizing downtime and maximizing productivity.

- Resists wear and corrosion, extending equipment lifespan and reducing maintenance costs.

- Applications

- Industrial equipment, Sealants, Fine chemicals, Rubber products, De-watering processes, Hydrocolloids, Biopharmaceuticals, Food processing, Extruded food products, Clay products, Firelogs, Catalysts, Rodenticides, Bulk molding compounds, Pharmaceuticals

- End products

- Food processing: snack pellets, De-watering processes: dehydrated plant matter products, Rubber products: rubber tubing, Clay products: clay briquettes, Pharmaceuticals: tablets, Catalysts: activated catalyst supports, Bulk molding compounds: bulk molded thermoset parts, Sealants: acrylic sealant strands, Hydrocolloids: xanthan gum extrudates, Rodenticides: extruded rodenticide pellets, Cornflakes, Gaskets, Firelogs: compressed sawdust firelogs, Bread crumbs, Extruded food products: pasta, Caplets, Biopharmaceuticals: biopolymer extrudates, Industrial equipment: custom industrial components, Fine chemicals: specialty chemical carriers

- Steps before

- Batch Size Configuration, Material Preparation, Ingredient Mixing, Material Feeding

- Steps after

- Material Changeovers, Cooling, Shaping and Forming, Packing

- Input ingredients

- bulk molding compound, carbon, catalyst, clay, firelog, food, hydrocolloid, rodenticide, rubber, sealant

- Output ingredients

- extrudate, cooked product, formed food, dewatered material, firelogs, molded compound, processed clay, shaped sealant, rubber products, rodenticide forms

- Market info

- The Bonnot Company is known for its expertise in manufacturing industrial extruders and cutting equipment, specializing in engineered-to-order solutions for various industries, including food, chemical, and ceramic sectors, with a reputation for quality and innovation.

- Size

- Custom variable sizes

- Screw Geometry

- Custom screw geometries

- Length-to-Diameter Ratio

- Customizable

- Horsepower

- Variable, based on design

- RPM Range

- Variable, based on design

- Temperature Control

- Precision with multiple zones

- Torque Load

- Designs suitable for higher torque loads

- Feed Sections

- Customizable to match batch size

- Cleanability

- Custom designs for cleanability

- Die Shape

- Custom die shape

- Batch vs. continuous operation

- Batch / Continuous

- Automation level

- Manual / PLC / SCADA

- Cleaning method

- CIP / Manual

- Changeover time

- Quick-change design

- Gear pump integration

- Integrated / Not Integrated

- Temperature control zones

- 5 separate zones

- Torque handling capacity

- High torque load

- Customization level

- High (custom design)

- Abrasion resistance

- Yes

- Biological compatibility

- Yes, depending on application

- Cleanability

- Custom designs for cleanability

- Corrosion resistance

- Custom contact component material selection

- Density/particle size

- Flexible design to accommodate

- Batch size accommodation

- Customizable

- Machine footprint

- Custom depending on extruder design and plant layout

- Bale feeder size

- Full bale feeder

- Feed/discharge method

- Custom feed sections

- Control panel type

- Full range of control options

- Compact footprint

- Customizable

- Discharge method

- Custom die shape and size

- Custom feed sections

- Accommodate batch size

- Screw Geometry,Die Shape

- Customized for application

- Contact component material selection

- Resist wear and corrosion

- Temperature Control

- Control Manifold

- Torque load designs

- Suitable for higher loads

- Custom bases

- Match centerline height / mobility

- Cleanability design

- Aid faster material changeovers

- Custom dies

- Match extrudate shape and size

- Control panel type

- Variety of control options