Modular packaging systems for diverse industries

Effortlessly adapt to market demands with versatile packaging systems, designed to handle diverse products and processes, ensuring seamless integration into your production line for enhanced efficiency and flexibility.

Optimizes and Automates Diverse Packaging Processes

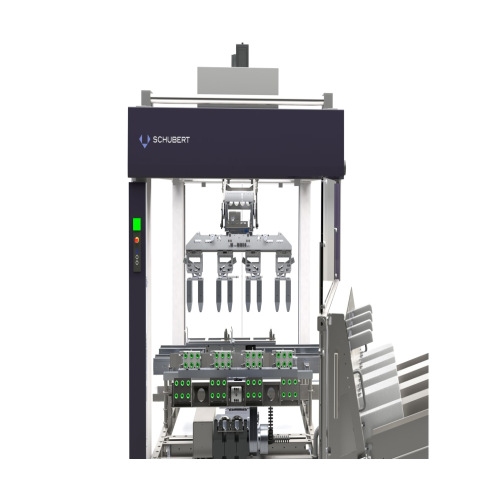

The modular packaging machines from Schubert are engineered to address the multifaceted packaging challenges faced by various industries such as food, pharmaceuticals, and cosmetics. Utilizing Schubert’s proprietary TLM technology, these machines enable seamless integration of processes like erecting, filling, and flow-wrapping, offering unparalleled flexibility for packaging diverse products from bottled beverages to blister-packed pharmaceuticals. With their scalable and preconfigured modules, these machines are designed for rapid deployment and high-speed operations. Schubert machines incorporate advanced robotic tools and a Vision System, ensuring precise handling of products ranging from fragile cosmetic creams to sturdy pet food pellets. The machines support energy efficiency initiatives with optimized motor control systems and are available in sturdy material configurations for enhanced durability. Furthermore, compliance with industry standards ensures reliable operation across all sectors, simplifying maintenance with integrated cleaning systems. Schubert offers customization and engineering support to tailor solutions to specific production needs, ensuring continuous operation and maximum throughput.

Benefits

- Enhances operational flexibility with modular, scalable design to handle varying packaging formats.

- Minimizes setup time and investment with preconfigured machine modules ready for quick deployment.

- Saves energy and reduces operational costs through optimized motor control and robotics.

- Maintains high product integrity with precision handling and integrated Vision System.

- Streamlines maintenance efforts with integrated cleaning systems and robust material configurations.

- Applications

- Food, Beverages, Snacks, Pet food, Confectionery, Cosmetics, Pharma, Bakery products, Dairy

- End products

- Cardboard-packaged blister alternatives, Cornflakes, Bottled beverages, Blister-packed pharmaceuticals, Chocolate biscuit rolls, Natural cosmetic creams, Granola, Pet food pellets

- Steps before

- Product preparation, Ingredient mixing, Pre-cooling, Item organization

- Steps after

- Palletizing, Quality inspection, Labeling, Distribution

- Input ingredients

- standard packaging tasks, food products, bakery products, confectionery, snacks, dairy products, beverages, pharma products, cosmetics, pet food, natural products

- Output ingredients

- erected cartons, filled cartons, closed cartons, trayed products, flowpacks, packaged products, recyclable packaging, cardboard packaging solutions

- Market info

- Schubert Group is renowned for its innovative packaging technology solutions, specializing in modular, highly flexible packaging machines for various industries, ensuring efficiency and precision in production lines.

- Modular Construction

- Yes

- Automation Level

- High

- Integration Capability

- Robots, Vision System, Transmodul

- Flexibility

- High, supports various packaging materials

- Sub-machines

- 1–26 sub-machines

- Preconfiguration

- Lightline Series

- Functionality

- Erecting, filling, closing, labelling, etc.

- Space Efficiency

- Compact design available

- Packaging Speed

- Customizable based on line configuration

- Control System

- VMS packaging machine control system

- Automation level

- PLC / SCADA

- Changeover time

- Short

- Batch vs. continuous operation

- Continuous

- Cleaning method

- CIP / Manual

- Energy efficiency

- High

- Flexibility in packaging formats

- High

- Modularity

- Modular construction

- Integration with existing systems

- Seamless

- Machine adaptability to new materials

- Flexible

- System components integration

- Electrical, Pneumatic, Mechanical

- Density/particle size

- 50–1000 µm

- Machine footprint

- Compact

- Discharge method

- Mechanical/Electrical/Pneumatic

- Control panel type

- Integrated/Touchscreen

- Control Panel Type

- HMI / Touchscreen

- Integration Possibilities

- PLC / SCADA / ERP compatible

- Modular Design

- Customizable TLM Sub-machines

- Robotic Tools

- Product-specific

- Machine Configuration

- Preconfigured Modules