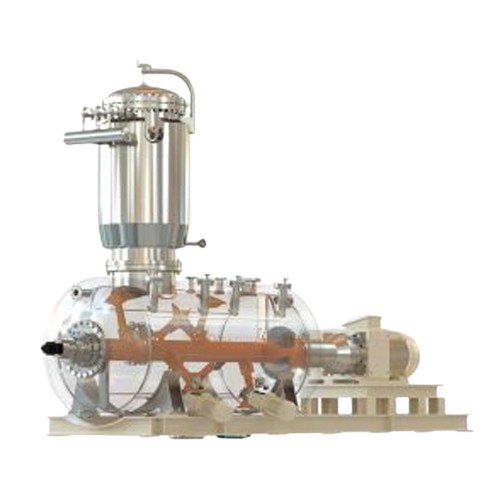

Horizontal vacuum paddle dryer for thermosensitive products

Achieve precise drying and mixing of high-viscosity, thermosensitive products with unmatched thermal efficiency, ensuring consistency and purity throughout batch operations. Ideal for processes demanding strict control over moisture levels and material properties.

Drying, Mixing, and Reacting Thermosensitive Materials

The Turbodry MHT-RS from Bachiller is a specialized horizontal vacuum paddle dryer and reactor engineered for handling high-viscosity and thermosensitive materials. This equipment employs a fully heated body and shaft design, coupled with high-speed rotating paddles, to achieve optimal thermal exchange and constant product renewal against the wall, thus ensuring efficient drying and mixing. It’s commonly utilized in industries such as pharmaceuticals, fine chemicals, and food processing for manufacturing active pharmaceutical ingredients, synthetic rubber, and fragrance oils.

The Turbodry operates in batch mode with capacities ranging from 10 to 30,000 liters, supporting vacuum levels down to 1 mbar. Equipped with advanced automation options, it offers robust control with optional hardware/software integration, including pilot plant models for scale-up validation. The design adheres to stringent safety and quality standards, such as ASME VIII div.1, AD-2000, and EN-13445, and is available in ATEX-certified executions for internal zones 0/20. Material finishes include mirror and electro polishing for sanitary conditions, ensuring compliance with cGMP for pharmaceutical applications. For ease of operation, it features a power retention filter, sampling valves, and optional choppers for lump breaking, making it suitable for diverse processing needs.

Benefits

- Reduces energy consumption due to highly efficient thermal exchange design.

- Accommodates a wide range of high-viscosity materials, enhancing operational flexibility.

- Ensures product consistency with precise temperature control and agitation settings.

- Supports rapid scale-up and trial production with pilot plant models.

- Meets international safety and quality standards, ensuring compliance across industries.

- Applications

- Cosmetics, Natural extracts, Pigments, Special waste treatment, Food, Chemicals, Polymers, Fine chemicals, Waste treatment, Biocides, Petrochemicals, Composites, Agrochemicals, Additives, Solvents, Resins, Pharmaceuticals, Plastics and polymers, Veterinary

- End products

- Industrial paint pigments, Active pharmaceutical ingredients, Emulsified biocides, Recycled solvents, Biodegradable polymers, Herbicide formulations, Vanilla extract, Flavor concentrates, Disinfectant wipes, Synthetic rubber, Fragrance oils, Epoxy resin composites, Thermoplastic resins, Polyurethane additives, Gel-based cosmetics

- Steps before

- Concentration, Effluent treatment, Evaporation, Slurry treatment

- Steps after

- Solvents recycling, Special waste treatment, Waste water treatment, Packing

- Input ingredients

- thermosensitive products, pseudo-plastic products, high viscosity materials, API’s, cosmetics components, crystals, food additives, natural extracts, pharmacy synthesis materials, veterinary ingredients, vitamins, chemical additives, PVC additives, agrochemicals, artificial marble, catalysts, cellulose, colorants, composites, concentration media, effluents, evaporation substances, fibers, graphite specialties, herbicides, pigments, polymers, resins, sealants, slurry, solvents, special waste, waste water, animal extracts, proteins

- Output ingredients

- dried substances, processed API’s, finished cosmetics, crystalized products, concentrated food additives, extracted natural ingredients, synthesized pharmacy products, veterinary pharmaceuticals, processed vitamins, formulated chemical additives, refined PVC additives, processed agrochemicals, finished artificial marble, processed catalysts, refined cellulose, processed colorants, finished composites, concentrated chemicals, treated effluents, evaporated components, processed fibers, refined graphite, processed herbicides, final pigments, processed polymers, finished resins, refined sealants, treated slurry, recycled solvents, treated special waste, processed waste water, refined animal extracts, processed proteins

- Market info

- Bachiller specializes in industrial engineered-to-order equipment, known for high-quality process equipment in the chemical, petrochemical, pharmaceutical, and food industries. They are recognized for their expertise in designing and manufacturing pressure vessels, reactors, and mixing equipment.

- Capacity

- 10 to 30, 000 liters

- Operation Temperature

- up to 350°C

- Operation Pressure

- 6 bar(g)

- Vacuum Level

- 1 mbar

- Batch Operation

- Yes

- Thermal Exchange

- Maximized

- Turbulence

- High

- Design Standards

- ASME VIII div.1, AD-2000, EN-13445

- CE Marking

- Yes

- Cycle Time

- Shortest drying cycles

- Hydraulic Operation

- Yes

- Polishing Option

- Mirror polished Ra ≤ 0.6 µm, Electro polishing ≤ 0.2 µm

- Power Retention Filter

- Available

- Choppers for Lump Breaking

- Available

- Sanitary Design

- cGMP

- Control Systems

- Hardware and software available

- ATEX Certification

- Execution for internal zone 0/20

- Batch vs. continuous operation

- Batch

- Automation level

- PLC

- Tightness level

- High

- Torque resistance

- Full torque utilization

- Cleaning method

- CIP

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Heat sensitivity

- Thermosensitive products

- Viscosity

- High viscosity processes

- Torque resistance

- High torque resistance

- Agglomeration risk

- Pseudo-plastic behaviour

- Discharge method

- Metal to metal seal outlet valve

- Mirror Polishing

- Ra ≤ 0.6 µm

- Electro Polishing

- ≤ 0.2 µm

- Control System

- Hardware and Software Options

- Pilot Plant Models

- Available