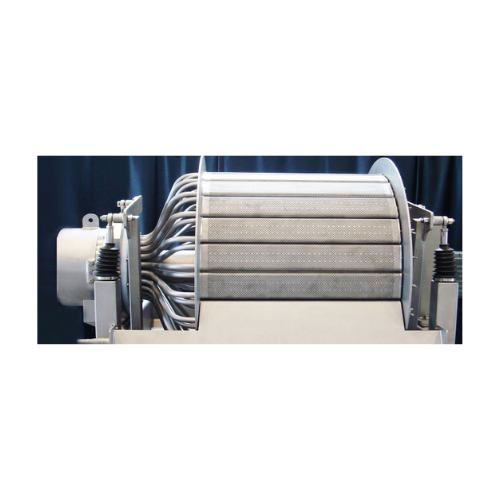

Industrial drum vacuum filter for filtration and washing

Efficiently manage filtration, washing, and dewatering tasks with advanced vacuum drum technology, ensuring rapid cloth changes and continuous production without compromising safety or quality, ideal for industries requiring high-precision solid-liquid separation.

Performs Continuous Filtration and Dewatering

The BoVac Drum Filter by BOKELA is a cutting-edge vacuum drum filter designed for continuous solid-liquid separation. Its distinctive feature is the modular design with replaceable filter cells, enabling quick cloth changes without halting production, significantly enhancing operational efficiency and work safety. Ideal for applications across minerals, chemicals, and pharmaceuticals, it supports end-products such as copper concentrate, sodium chloride, and acetylsalicylic acid tablets. Capable of high-throughput operations, the BoVac Drum Filter efficiently processes a variety of slurries and filter cakes. Its PLC-controlled system allows seamless integration into existing production lines, while features like adjustable wash bars and a CIP system ensure easy, thorough cleaning and maintenance. Available in various material options to suit corrosive environments, it aligns with stringent GMP and FDA standards, making it a versatile choice for multiple industries.

Benefits

- Enhances productivity with quick cloth changes that minimize operational downtime.

- Achieves high purity levels through precise filtration and efficient washing processes.

- Streamlines integration with existing systems via plug-and-play setup and automation.

- Supports diverse applications with customizable settings for various product types.

- Ensures compliance with industrial standards, maintaining quality and safety in sensitive environments.

- Applications

- Chemicals, Dyes, Organic pharmaceuticals, Pharmaceutical intermediates, Textile dye products, Fillers, Food products, Minerals, Gypsum, Plastic intermediates, Salt, Pigments, Pharmaceuticals

- End products

- Sodium chloride, Direct dye, Reactive dye, Bakery yeast, Acetylsalicylic acid tablets, Polyethylene resin, Titanium dioxide, Paracetamol, Ibuprofen intermediates, Plaster of paris, Sodium carbonate, Calcium carbonate filler, Copper concentrate

- Steps before

- Crystallization, Precipitation, Suspension Preparation

- Steps after

- Packing, Coating, Dewatering

- Input ingredients

- crystallization and precipitation suspensions, plastic intermediates, pharmaceutical intermediates, pigments, fillers, dyes, gypsum, organic pharma intermediate, textile dye product

- Output ingredients

- clean filter cake, washed solids, dewatered filter cake

- Market info

- BOKELA is known for its expertise in engineering and manufacturing filtration technology and equipment, particularly for solid-liquid separation processes in various industries, offering innovative, high-performance solutions with a strong reputation for reliability and efficiency.

- Filter Area

- 1–9 m²

- Drum Diameter

- 0.9–1.9 m

- Length of Drum

- 0.375–1.6 m

- Number of Single Cells

- 24–36

- Automation

- Fully automatic

- Cycle Time for Cloth Change

- Approx. 1–2 hours

- Wash Ratio

- WR = 0.2 to 2 [kg wash water/kg solids]

- Operating Characteristics

- High Temperature and Hazardous Areas

- Plug,Play

- Yes

- Automation level

- Fully automatic

- Batch vs. continuous operation

- Continuous

- Changeover time

- Approx. 1–2 hours

- CIP/SIP

- CIP system available

- Cleaning method

- Fully automatic with CIP

- Energy efficiency

- Compact and energy-efficient operation

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Filter Cloth Changeover Time

- 1–2 hours

- Control panel type

- PLC/SCADA

- Compact footprint

- Yes

- Drum size

- 0.9–1.9 m diameter

- Filter area

- 1–9 m²

- Discharge method

- Compressed air blow-back

- Filter area size

- 1 m² to 9 m²

- Filter cell design

- Exchangeable single cells

- Optional features

- Encapsulation, Exhaust hood, CIP system

- Operation in hazardous areas

- Yes

- Temperature tolerance

- High temperatures

- Washing system

- Cake wash

- Control panel type

- Plug, Play Automation

- Filtrate removal system

- Leading and trailing filtrate pipes