High energy untra fine ball mill

Achieve ultra-fine particle sizes rapidly with this high energy milling solution, designed to deliver unrivaled grinding precision and efficiency while maintaining temperature control—ideal for complex material processing in research and development settings.

Achieves Ultra-Fine Particle Size Reduction

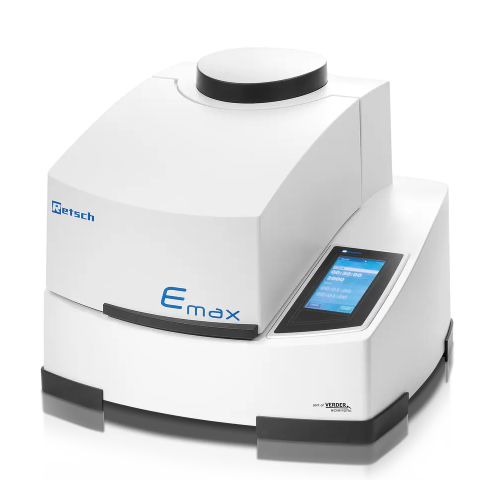

The Emax from Retsch GmbH is a high energy ball mill specifically designed for ultra-fine grinding applications. Unique in its category, the Emax combines high-frequency impact, intensive friction, and controlled circular jar movements to rapidly achieve target particle sizes in the submicron range.

Ideal for sectors such as pharmaceuticals, ceramics, and metallurgy, it produces stainless steel powders, ceramic tiles, and organic compounds with precision. With two grinding stations, it accommodates jars from 50 ml to 125 ml, enabling batch processing for both dry and wet grinding. The water-cooled system allows for continuous operation by effectively dissipating heat generated during milling, eliminating the need for cooling breaks typical of traditional ball mills.

The Emax’s sophisticated GrindControl system monitors and maintains optimal temperature and pressure, enhancing process accuracy and repeatability. In terms of efficiency, its variable-speed motor vastly reduces energy consumption. All components in contact with materials are available in stainless steel, tungsten carbide, or zirconium oxide, ensuring chemical compatibility and minimizing contamination.

Additionally, the Emax integrates seamlessly with laboratory data systems via USB and LAN interfaces, while its robust construction and CE certification underscore its safety and reliability. Designed for ease of maintenance, it supports quick jar and ball changes to maximize uptime, delivering unparalleled support for demanding research and development environments.

Benefits

- Achieves rapid particle size reduction, reducing production time and increasing efficiency.

- Continuous operation with water-cooled system minimizes downtime and maximizes throughput.

- Precise temperature and pressure controls maintain sample integrity, ensuring consistent results.

- Minimizes contamination risks with material options suitable for sensitive applications.

- Seamless data integration via USB and LAN interfaces supports efficient process monitoring and reporting.

- Applications

- Waste samples, Recycling materials, Chemical products, Sewage sludge, Agriculture products, Minerals, Pigments, Semi-precious stones, Engineering materials, Cement, Polymers, Soils, Metallurgy samples, Glass, Coal, Medicine products, Geology samples, Ceramics, Electronics materials, Construction materials, Pharmaceuticals, Fibers, Ores, Clays, Gypsum, Alloys, Concrete

- End products

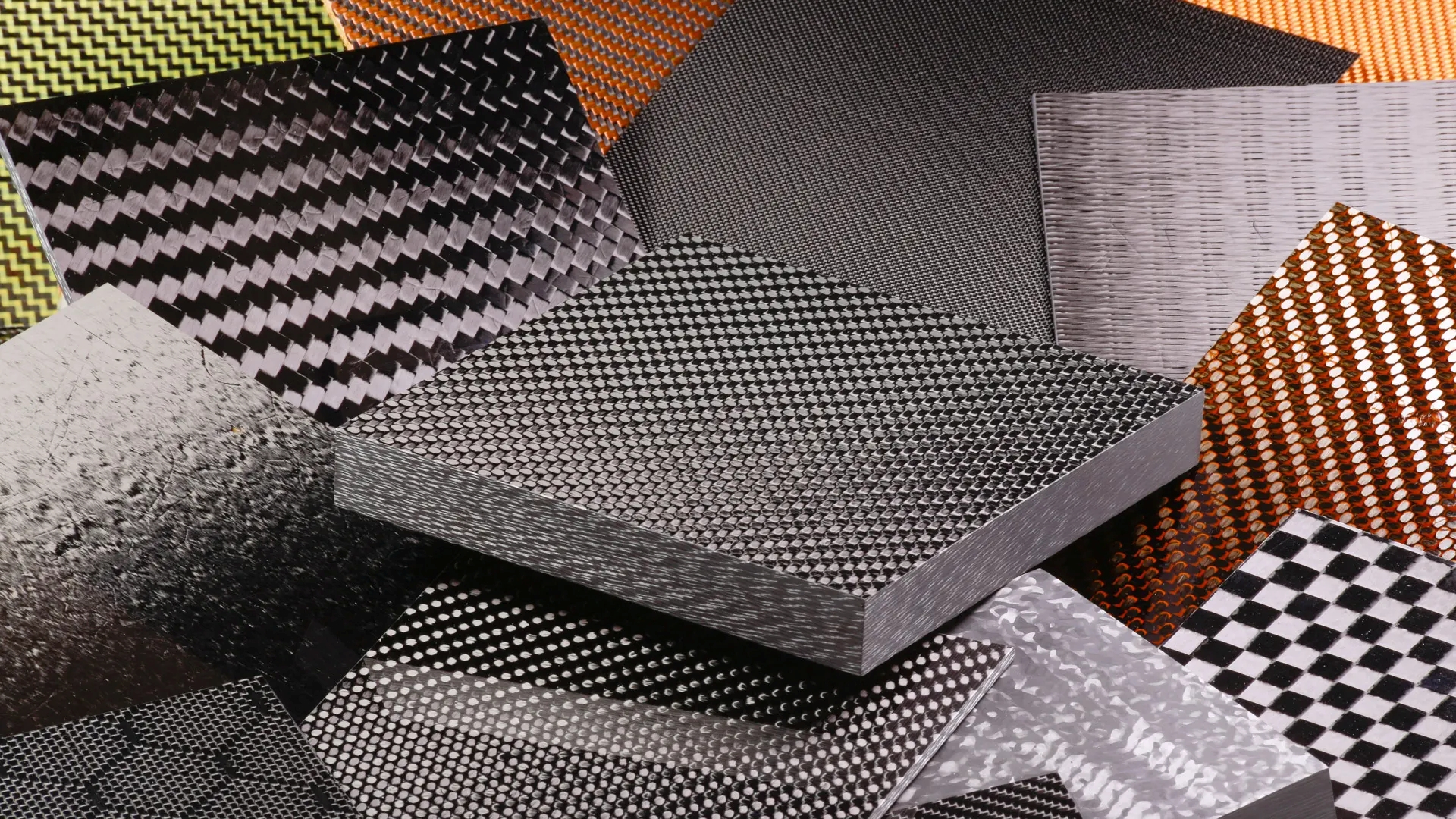

- Activated carbon, Otc medications, Carbon fiber sheets, Plastic granules, Topsoil modifiers, Treated biosolids, Stainless steel powders, Industrial waste by-products, Gemstone beads, Rock core samples, Insulation materials, Ceramic tiles, Portland cement, Drywall panels, Iron ore pellets, Recycled metals, Circuit boards, Ink pigments, Tablet formulations, Clay bricks, Reinforced concrete, Alloy samples, Fertilizer granules, Organic compounds, Copper concentrates, Optical glass

- Steps before

- Sample Preparation, Cutting, Crushing, Pre-grinding

- Steps after

- Sieving, Homogenization, Mixing, Analysis

- Input ingredients

- alloys, bones, carbon fibres, catalysts, cellulose, cement clinker, ceramics, chemical products, clay minerals, coal, coke, concrete, fibres, glass, gypsum, iron ore, kaolin, limestone, metal oxides, minerals, ores, paper, pigments, plant materials, polymers, quartz, semi-precious stones, sewage sludge, slag, soils, tea, tobacco, waste samples, wood, medium-hard materials, hard materials, brittle materials, fibrous materials

- Output ingredients

- extremely fine particles, ultra-fine grinding, submicron range, narrow particle size distribution, final fineness < 80 nm

- Market info

- RETSCH is known for its high-quality laboratory equipment for sample preparation and particle size analysis, including mills, crushers, and sieve shakers, praised for their precision, durability, and reliability in research and industrial applications.

- Max Speed

- 2000 rpm

- Feed Size

- Up to 5 mm

- Final Fineness

- 0.08 µm

- Grinding Stations

- 2

- Jar Sizes

- 50 ml, 80 ml, 125 ml

- Temperature Control

- Yes, min and max temperature can be defined

- Cooling System

- Integrated water cooling

- Drive Power

- 2600 W

- Power Consumption

- ~ 3100 W (VA)

- Electrical Supply

- 200-240 V, 50/60 Hz

- Protection Code

- IP 30

- Interface

- USB / LAN (RJ45)

- Weight

- ~ 120 kg

- Dimensions (W x H x D)

- 625 x 525 x 645 mm

- Grinding Balls Size

- 0.1 mm to 25 mm

- Working mechanism

- Impact and friction

- Grinding speed

- 300 - 2000 min-1

- Batch vs. continuous operation

- Batch

- Temperature control

- Water cooling, temperature-controlled grinding

- Aeration control

- Aeration lids for atmosphere control

- Automation level

- Temperature and pressure monitoring with GrindControl

- Grinding jar geometry

- Unique oval shape with circular jar movements

- Cycle program capability

- Storable SOPs

- Abrasion resistance

- Yes (stainless steel, tungsten carbide, zirconium oxide)

- Corrosive resistance (e.g. acids)

- Yes (tungsten carbide, zirconium oxide)

- Density/particle size

- 0.08 µm final fineness

- Cleanability

- Yes (water cooling system)

- Patent / Utility patent

- US 8, 042, 754 B2

- Machine footprint

- W x H x D closed

- Weight

- ~ 120 kg

- Control panel type

- Touchscreen

- Grinding jar size

- 50 ml / 80 ml / 125 ml

- Grinding stations

- 2

- Grinding jar shape

- Oval

- Material of grinding tools

- Stainless steel, tungsten carbide, zirconium oxide

- Discharge method

- Aeration lids available

- Control panel type

- Touchscreen

- Integration possibilities

- USB / LAN (RJ45)

- Grinding jar material

- Stainless steel / Tungsten carbide / Zirconium oxide

- Cooling modes

- Internal / External chiller / Tap connection

- Aeration lid

- Special lid for atmosphere control

- Stored SOPs and cycle programs

- 10