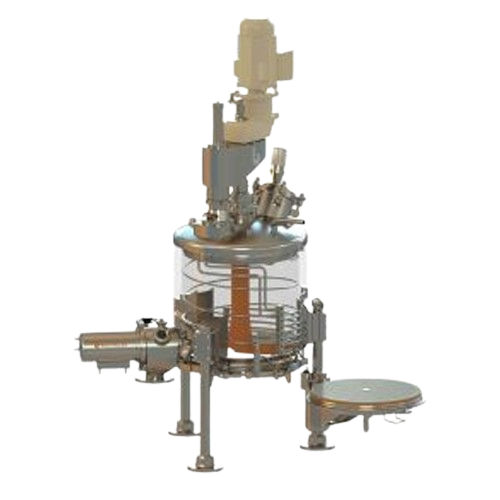

Agitated nutsche filter for solid-liquid separation

Ensure high-purity solid-liquid separation with minimized contamination risks and efficient handling of hazardous materials, catering to complex processing needs in batch operations.

Performs Filtration and Separation of Solid-Liquid Mixtures

The Agitated Nutsche Filter (FNB) from Bachiller is designed for efficient solid-liquid separation in industries such as pharmaceuticals and fine chemicals. This equipment operates by pressurized filtration, ensuring hermetic production to prevent contamination and preserve product purity. Suitable for applications including API production and pigment processing, it supports capacities ranging from 19L to 15,000L, with filtering surfaces between 0.07m² and 15m². Operating at pressures up to 3 bar(g) and temperatures reaching 200°C, it integrates seamlessly with batch operations, offering full or semi-automatic processes. The Agitated Nutsche Filter features a versatile filter media selection—textile, synthetics, metal—to ensure compatibility with diverse chemical environments. Built to comply with GMP and EHEDG standards, it is suitable for sterile applications and cleanroom installations. Maintenance is simplified with easy filter cloth exchange and a CIP/SIP system testable with the Riboflavin test. The unit supports further customization with options for mirror polishing, tight thermal insulation, and ATEX certified configurations, meeting rigorous production and safety demands.

Benefits

- Ensures contamination-free production with hermetic sealing.

- Enhances product purity across various granulometries, critical for high-quality outputs.

- Adapts to cleanroom environments, meeting stringent pharmaceutical standards.

- Minimizes cleaning and maintenance time with efficient CIP/SIP systems.

- Offers operational flexibility with full and semi-automatic configurations.

- Applications

- Polymers, Vitamins, Biotechnology, Colorants, Fine chemicals, Food additives, Minerals, Antibiotics, Chemical additives, Flavours and aromas, Natural extracts, Metallic powders, Petrochemicals, Api's, Catalysts, Pigments, Pharmaceuticals

- End products

- Lycopene food color, Essential oil distillates, Ibuprofen syrup, Copper sulfate, Peppermint extract, Ascorbic acid granules, Paracetamol capsules, Anodized aluminum powders, Synthetic resin granules, Azithromycin tablets, Beta-carotene supplements, Ethylene propylene copolymer, Rubidium catalyst, Chromium-packed supplements, Food-grade titanium dioxide, Vanillin powder

- Steps before

- Chemical reaction, Suspension preparation, Emulsification, Grinding

- Steps after

- Separation, Washing, Sterilization, Packing

- Input ingredients

- antibiotics, active pharmaceutical ingredients (APIs), biotechnology compounds, colorants, crystals, essences, flavours, natural extracts, peptides, pharmaceutical raw materials, vitamins, chemical additives, catalysts, metallic powders, minerals, pigments, polymers, food additives, animal extracts, food colorants, aromas, vitamin complements

- Output ingredients

- pure substances, homogeneous products, high purity products, granulometry-independent products

- Market info

- Bachiller specializes in industrial engineered-to-order equipment, known for high-quality process equipment in the chemical, petrochemical, pharmaceutical, and food industries. They are recognized for their expertise in designing and manufacturing pressure vessels, reactors, and mixing equipment.

- Filtering Surface

- 0.07–15 m²

- Operation Capacity

- 19–15, 000 L

- Operating Pressure

- 3 bar(g)

- Operating Temperature

- Up to 200°C

- Batch Operation

- Yes

- Bottom Lifting and Lowering

- Automatic

- Bottom Sealing System

- SUPERCLAMP

- Cake Washing System

- Yes

- Filter Design

- Hermetic / GMP / EHEDG

- Filtering Cloth

- Textile / Synthetic / Metal / Multilayer / Ceramic

- Compliance

- ASME VIII div.1 / AD-2000 / EN-13445

- Internal Polishing

- Ra ≤ 0.6 µm / 0.2 µm (electro-polished)

- CIP/SIP Systems

- Available

- Agitator Seal

- Special Sterile Mechanical Seal

- Nitrogen Seals

- Floating Mechanical

- Vacuum and Heating Unit

- Yes

- Automation level

- Full automatic / Semi-automatic

- Batch vs. continuous operation

- Batch

- CIP/SIP

- CIP/SIP systems, validatable

- Cleaning method

- CIP / Manual

- Changeover time

- Reduced

- Energy efficiency

- Low energy consumption

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Cake Washing System

- Yes

- Filtering Surface

- 0.07–15 m²

- Operation Capacity

- 19–15, 000 L

- Operation Pressure

- 3 bar(g)

- Operation Temperature

- Up to 200º C

- Bottom Filter Type

- Automatic lifting and lowering

- Bottom Sealing System

- SUPERCLAMP

- Cake Discharge Method

- Lateral valve

- Filtering cloth type

- Textile / synthetics / metal / multilayer / ceramic

- Internal surface finish

- Mirror polished Ra ≤ 0.6 µm

- Internal surface finish

- Electro polished Ra≤ 0.2 µm

- External surface finish

- Up to mirror polishing

- Agitator seal type

- Special sterile mechanical seal

- Sealing system

- SUPERCLAMP bottom sealing

- Thermal insulation

- Tight with welded stainless steel cover

- Control system

- Hardware and Software control