Laboratory crossflow filtration test system

Efficiently test and determine optimal filtration parameters with this portable crossflow system, ideal for analyzing complex suspensions and selecting appropriate filter media for diverse operations.

Performs Dynamic Crossflow Filtration for Small Samples

The BoCrossTest from BOKELA is an innovative laboratory-scale dynamic crossflow filtration device designed to evaluate filtration processes with small sample volumes. It distinguishes itself with its dynamic crossflow filtration technology, leveraging shear stress to prevent solid build-up on filter media. Applicable across industries like chemicals, pharmaceuticals, and ores and minerals, it effectively processes liquids, slurries, and cakes. BoCrossTest supports both batch and continuous operations, with flexible filter media options such as polymer membranes, metal mesh, and ceramic membranes. Its compact, portable design makes it ideal for laboratory settings, with easy integration into R&D and quality control departments. Operating under a maximum pressure of 10 bar and temperatures up to 170°C, it’s available in materials like stainless steel for enhanced corrosion resistance. Offering fast media changes and straightforward handling, the BoCrossTest supports extensive filtration testing, providing crucial data for optimizing industrial-scale processes and ensuring product purity.

Benefits

- Enables precise filtration analysis for improved process optimization.

- Saves resources with minimal sample quantity requirements.

- Facilitates easy transition from laboratory testing to full-scale production.

- Versatile with multiple filter media compatibility for varied applications.

- Enhances laboratory safety and efficiency with portable, compact design.

- Applications

- Pharmaceutical precursors, Chemical and pharmaceutical sector, Fillers and dyes, Pigments, Plastic intermediates, Ores and minerals

- End products

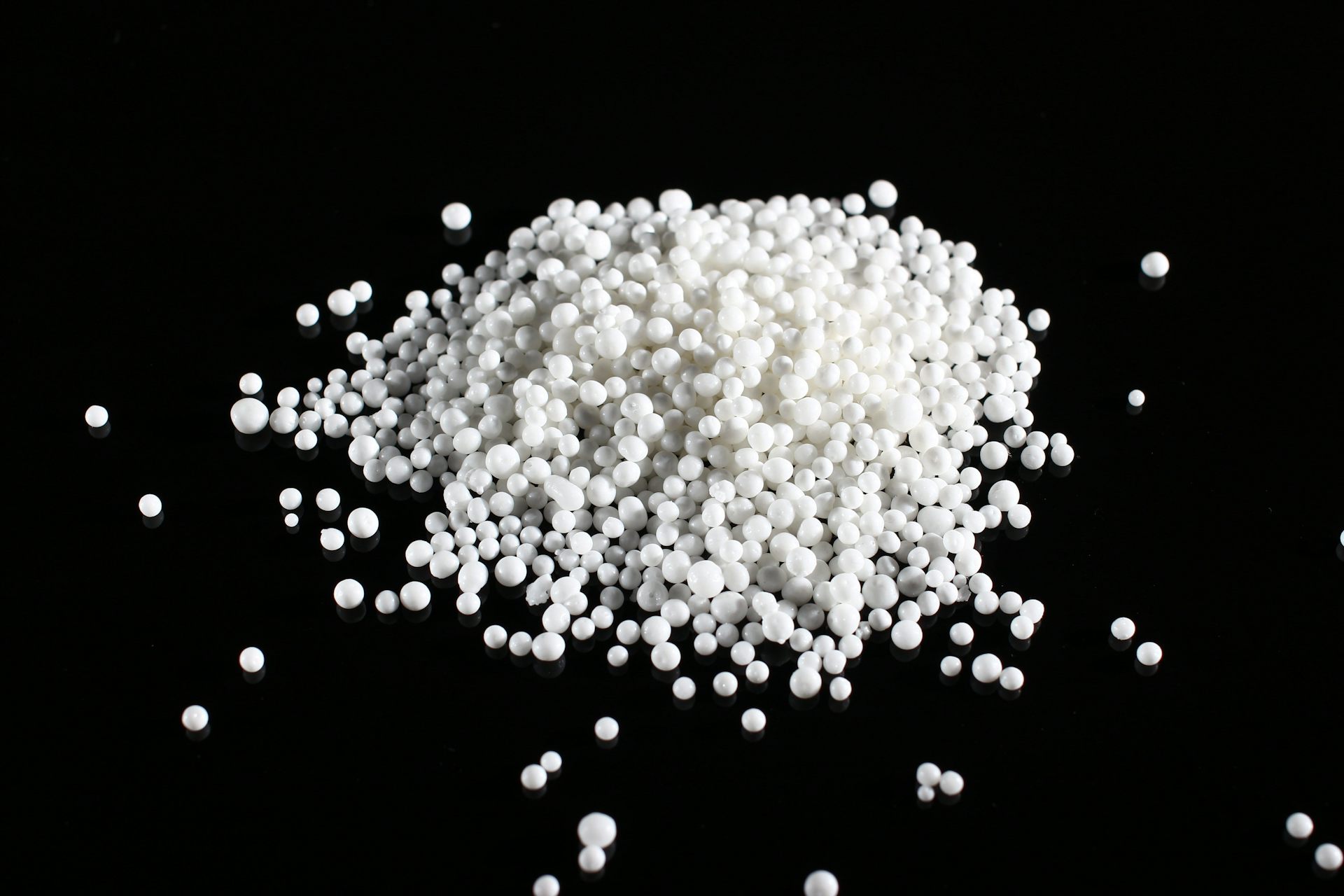

- Dyes, Titanium dioxide, Ammonium nitrate, Active pharmaceutical ingredients (apis), Bauxite concentrate, Propylene glycol, Iron oxide pigments, Calcium carbonate

- Steps before

- Sampling, Preparation of suspensions

- Steps after

- Filtration evaluation, Filter media testing, Solid separation, Filter cake washing

- Input ingredients

- suspensions, sample quantities, various suspensions, polymeric membranes, metal mesh, ceramic membranes

- Output ingredients

- filtrate, filtered solids, filter cake, classified particles, thickened suspensions

- Market info

- BOKELA is known for its expertise in engineering and manufacturing filtration technology and equipment, particularly for solid-liquid separation processes in various industries, offering innovative, high-performance solutions with a strong reputation for reliability and efficiency.

- Filter area

- 0.013 m²

- Filtration pressure

- max. 10 bar

- Operation temperature

- max. 170 °C

- Sizes (L × W × H)

- 736 × 585 × 628 mm

- Weight

- 63 kg

- Drive

- 0.55 kW / IP 65

- Mechanical seal

- Double acting mechanical seal

- Operation mode

- membrane filtration / sieve filtration with intermittent backwashing

- Working mechanism

- Dynamic crossflow filtration

- Operation mode

- Discontinuous/Continuous

- Shear stress effect

- Prevents solid deposits

- Batch vs. continuous operation

- Both

- Filter media changeover

- Fast change

- Corrosive resistance (e.g. acids)

- Stainless Steel 1.4404, 1.4307

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- ATEX certification

- II/3G Ex h IIB T3 Gc X

- Machine footprint

- Complete

- Weight

- Complete

- Sample volume

- 1 to 40 liters

- Filter area

- 0.013 m²

- Portable

- Yes

- Filter media type

- Polymer membranes / Metal mesh / Ceramic membranes

- Operation mode

- Discontinuous / Continuous

- Casing material

- 1.4404 / 1.4307

- Temperature range

- Max 170°C

- Pressure range

- Max 10 bar

- Size options

- Complete / Basic

- Cooling feature

- Available / Not available

- ATEX certification

- Optional