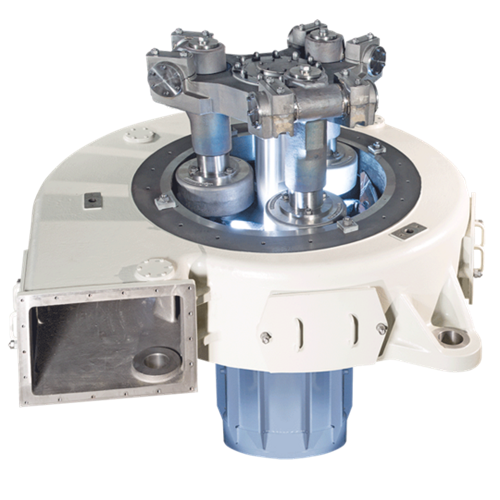

Pendulum mill for fine grinding and drying

Achieve efficient and precise grinding for soft to medium-hard materials while minimizing energy consumption and maintaining a narrow particle size distribution.

Grinds, Deagglomerates, Dries, and Classifies Materials

The Pendulum Mill PM from NEUMAN & ESSER is a robust and efficient grinding solution ideal for processing a wide range of materials. This horizontal roller mill is designed for fine grinding and drying, with applications across industries such as chemicals, ceramics, and energy. The mill operates with a pendulum roller system that ensures consistent particle size distribution through a combination of grinding, deagglomeration, drying, and classification. It features a production capacity ranging from 0.1 to 150 tons per hour, addressing the needs of operations requiring both small and large scale throughput.

With its integrated high energy efficiency design, the Pendulum Mill achieves fine particle distribution (10 μm – 1,000 μm) while minimizing energy consumption. The system supports continuous high-speed operations with manual controls for precise adjustments. Constructed with durable materials, it offers customization options for wear protection and specific material compatibility, making it suitable for demanding environments.

Ideal for manufacturing end-products like ceramic tiles, plasterboard, and titanium dioxide pigments, the Pendulum Mill PM aligns seamlessly with various processing lines. NEUMAN & ESSER provides comprehensive engineering support, ensuring the equipment is tailored to meet your precise operational and material requirements.

Benefits

- Increases production efficiency with versatile grinding and drying capabilities.

- Minimizes energy costs through high-efficiency operation and design.

- Ensures consistent product quality with precise particle size control.

- Adapts to diverse industry needs with customizable material options.

- Reduces operational noise and vibration for improved workplace safety.

- Applications

- Ceramics, Clay, Fossil fuels, Paint, Minerals, Technical limestone cycle, Chemical products, Gypsum, Pigments, Fertilizers, Oilfield minerals

- End products

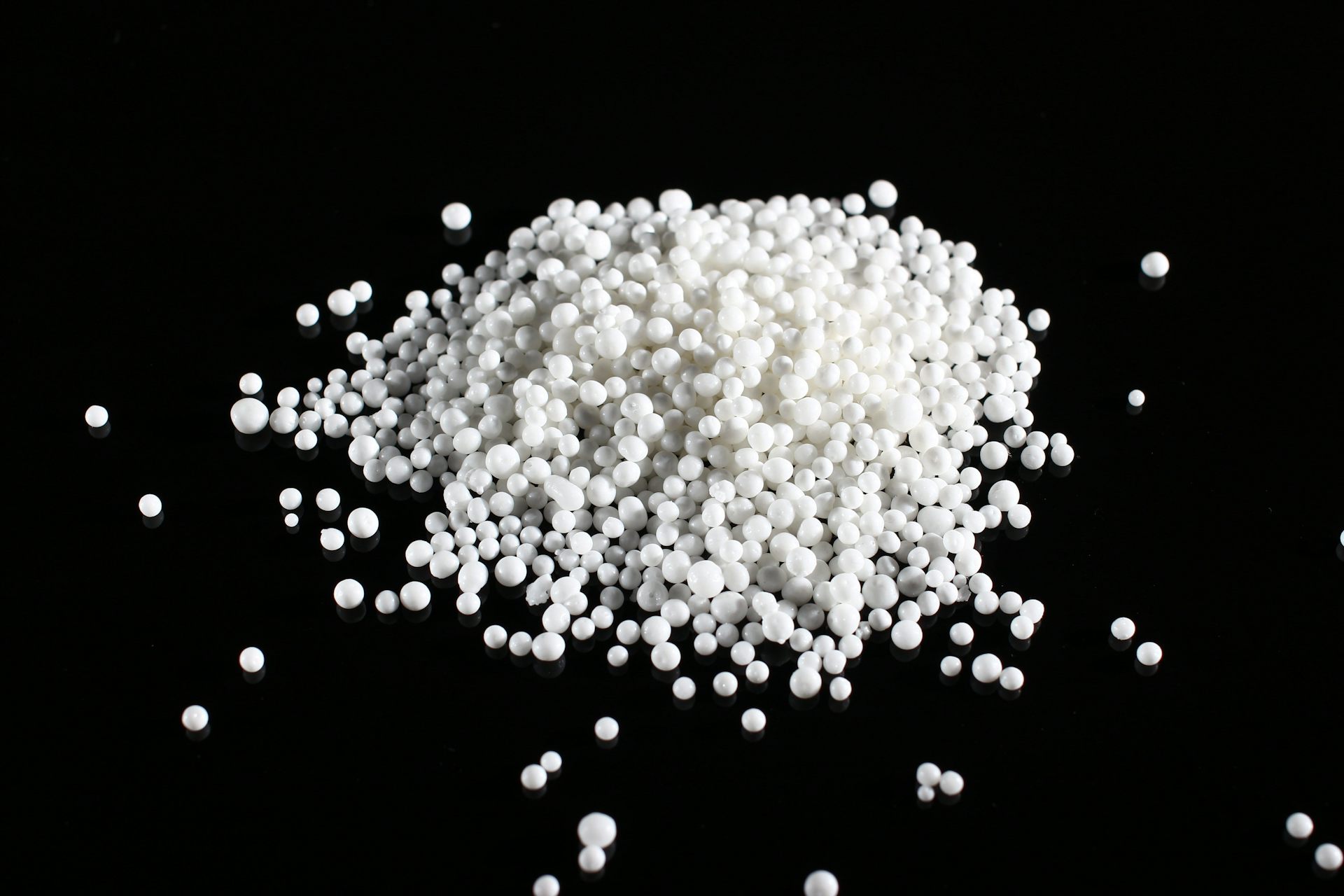

- Ground calcium carbonate (gcc), Detergent phosphates, Ammonium nitrate, Emulsion paints, Ceramic tiles, Barite mud, Petroleum coke, Talcum powder, Plasterboard, Porcelain, Titanium dioxide pigments

- Steps before

- Material Preparation, Crushing, Drying

- Steps after

- Classification, Separation, Packing

- Input ingredients

- clay, bentonite, barite, phosphate, coal, burnt lime, limestone, talc, pigments, chemical products, ammonium sulfate, kaolin, china clay, bauxite, petroleum coke, graphite, sodium bicarbonate, crystalline silicic acid, autoclaved alpha gypsum, natural gypsum, calcined gypsum

- Output ingredients

- fine grinding material, ground particles, classified particles

- Market info

- Neuman & Esser Group is known for its expertise in manufacturing compressors and grinding systems. They hold a strong reputation for providing durable, high-quality engineered-to-order equipment, particularly in the oil and gas, chemical, and energy industries.

- Grinding system

- Pendulum mill

- Grinding ring diameter

- 500 mm – 2, 700 mm

- Feed material particle size

- 0 – 50 mm

- Feed material moisture

- 0 – 35 %

- Particle size limitation

- 10 μm – 1, 000 μm

- Throughput

- 0.1 t/h – 150 t/h

- Mill power

- 10 kW – 600 kW

- Air quantity

- 3, 000 m³/h – 210, 000 m³/h

- Number of pendulums

- 1 – 5

- Energy efficiency

- High

- Dust collection

- Integrated classifier and downstream aggregate

- Grinding capability

- Soft to medium-hard materials

- Grinding Mechanism

- Roller / Horizontal Mill

- Grinding Rollers Movement

- Medium Speed

- Material Transport

- System Air

- Operational Mode

- Continuous

- Particle Classification

- Classified for Fineness Control

- Re-Grinding Capability

- Automatic Feedback for Coarse Product

- Energy Requirements

- Minimal

- Particle Size Range

- 10 μm – 1, 000 μm

- Throughput

- 0.1 t/h – 150 t/h

- Wear Protection Options

- Tailor-made

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Grinding ring diameter

- 500 mm – 2, 700 mm

- Number of pendulums

- 1 – 5

- Control panel type

- PLC-controlled

- Wear protection

- Tailor-made