Making Bentonite Clay

Find innovative production technology for making bentonite and connect directly with world-leading specialists

Bentonite is a clay derived from the alteration of volcanic ash. Bentonite is solid, so after extracting it from the deposits, it has to be crushed and dried to reduce its moisture content up to 15%.

technology picks for producing bentonite

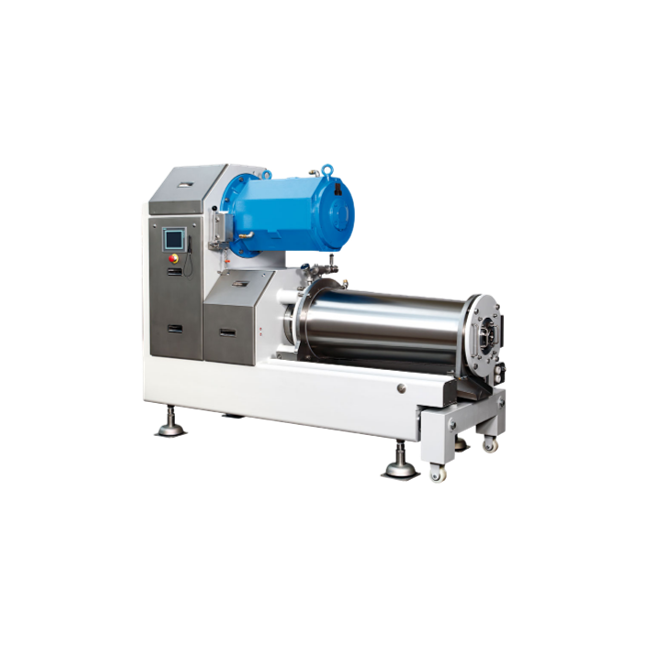

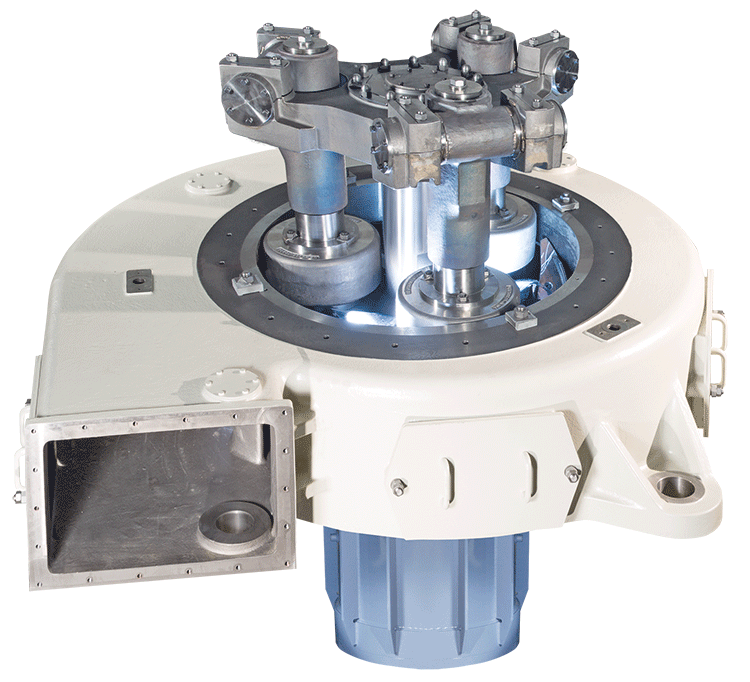

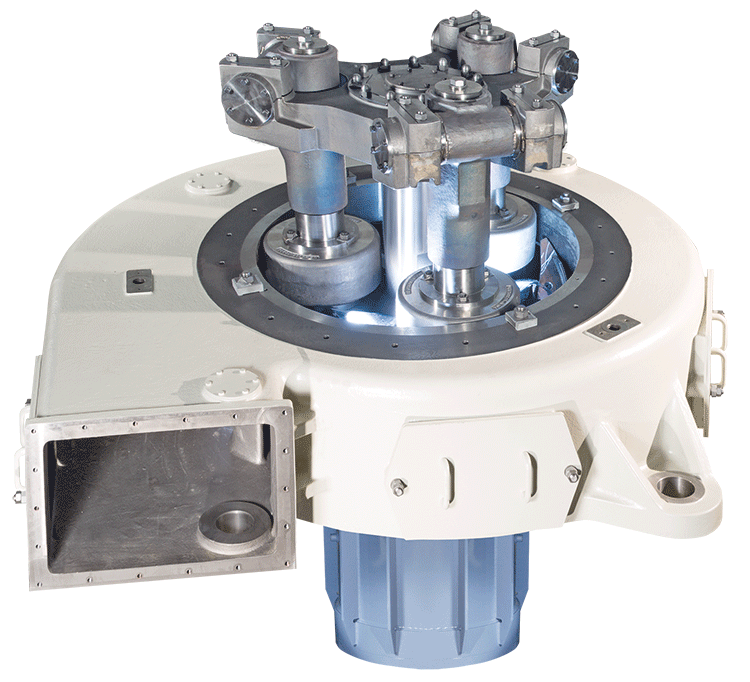

Grinding and drying of bentonite

After crushing and drying mined bentonite, this clay mineral is usually processed through a...

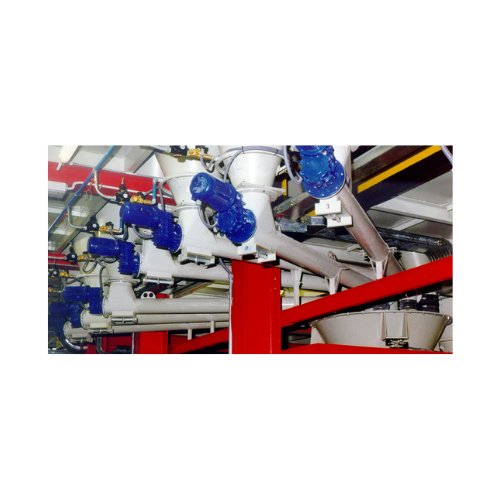

Tubular screw conveyor for powdery and granular materials

Optimize your material handling processes with a versatile sol...

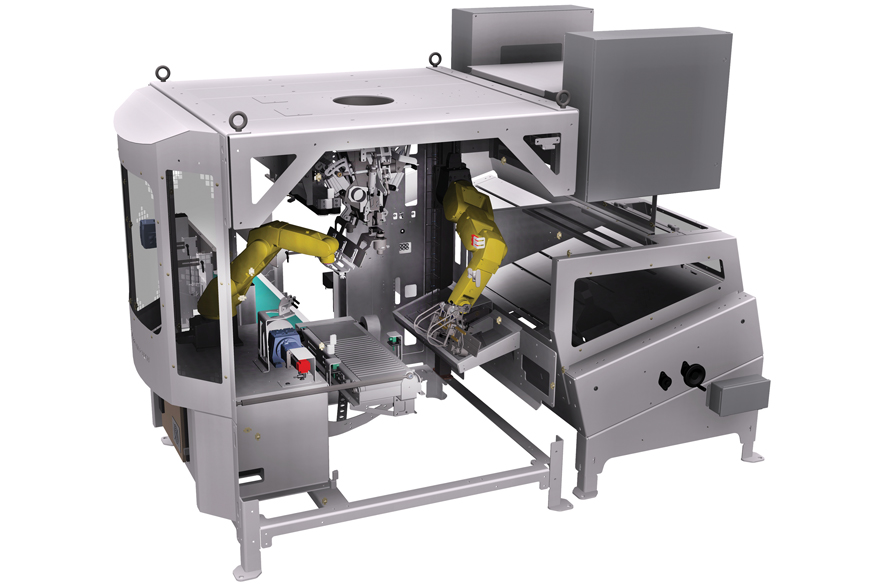

Automatic bagging machine for open mouth bags

Open mouth bags allow for a variety of different products to be packaged, wi...

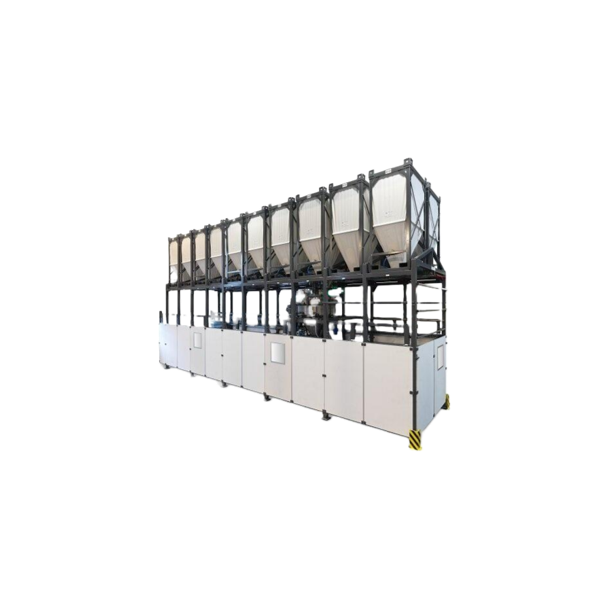

Batch weighers for large-volume powder and granulate weighing

Ensure precise ingredient dosing and streamline your produ...

Select your bentonite process

Tell us about your production challenge

What is bentonite clay?

The two different names, bentonite or montmorillonite clay, come from the places where it was used and found for the first time, Fort Benton, United States, and Montmorillon, France. It mainly consists of montmorillonite, a clay mineral belonging to a class of phyllosilicates called smectites which when in contact with a liquid start swelling. It can absorb water up to ten times its own weight. There are two types of bentonite according to the mineral mostly present in it: calcium bentonite and sodium bentonite.

Calcium bentonite clay for skincare products

Major deposits of calcium bentonite are in Greece, Australia, and Turkey. Compared to sodium bentonite, calcium bentonite has a low level of swelling and has a more greenish-yellow tone. Calcium bentonite is typically used in skincare as a face mask, for instance. It carries a negative charge that binds to the positive charge of the toxins in your skin to draw them out. It can also be ingested to remove the toxins for your body.

Sodium bentonite clay for industrial uses

Sodium bentonite is also known as swelling clay because of its high level of swelling. It has a gray color and is used in industrial applications. You can find it as drilling mud and as a binder in the foundry as well as a clarifying agent in the production of beer or wine. It acts as a water softener to remove calcium from hard water. Its high absorption ability makes it a useful natural sealant to line the base of landfills or to seal roads.

Bentonite processing – How to dry and grind your bentonite clay

Grinding and drying are key steps when processing bentonite. When bentonite comes out of the mines, it is solid and its natural moisture content is about 30%. Therefore, you need to dry it to reduce the moisture. A dryer brings the moisture down to allow the bentonite to be pulverized. A grinder usually is used to reduce the particle sizes of the material.

Processing steps involved in bentonite making

Which bentonite technology do you need?

Laboratory drum mill for large sample volumes

Efficiently process large volumes of diverse materials into precise particle...

Planetary ball mill for high throughput grinding

For precise material engineering, achieve efficient size reduction, homog...

Pendulum mill for fine grinding and drying

Achieve efficient and precise grinding for soft to medium-hard materials while ...

Ultrafine classifier for precise particle separation

Gain precise control over particle size with this ultrafine classifi...

High precision air classifier for fine powder processing

Achieve precise particle separation and optimize throughput in y...

Advanced sludge dewatering for sewage treatment plants

Optimize sludge dewatering with a centrifuge that enhances separat...

Wine clarification flotator

Achieve superior wine clarity efficiently by integrating a single-tank flotation solution that s...

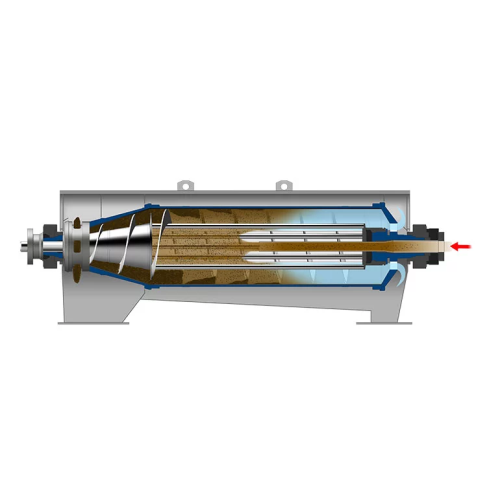

2-phase separating decanter for chemical and mineral processing

Ensure precise separation and optimal moisture control i...

Heavy-duty tubular screw conveyor for bulk solids

Optimize your production line with a durable solution for uninterrupted...

Tubular screw conveyor for powdery and granular materials

Optimize your material handling processes with a versatile sol...

High-temperature screw conveyors for bulk solids

Designed for extreme conditions, these conveyors handle high-temperature ...

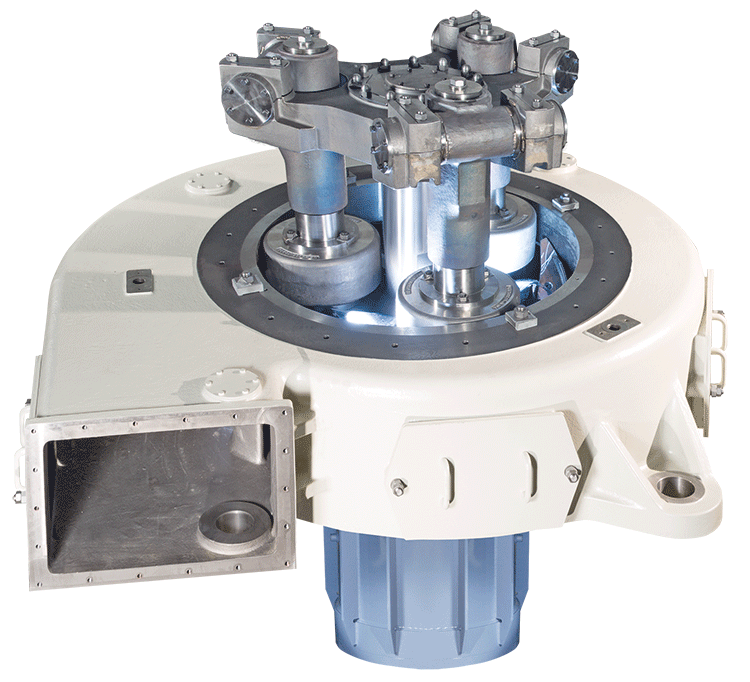

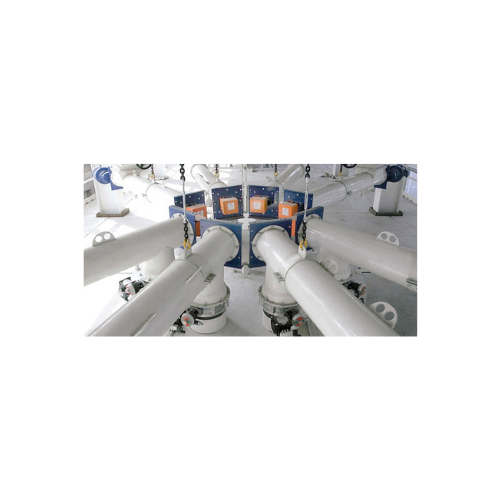

Vertical ring-roll mill for pulverizing minerals

Achieve precise particle size control and efficient material processing w...

Bulk reception solution for industrial material handling

Optimize your operations with an above-ground bulk reception sys...

Grinding and drying of CaCO3

Widely used in the construction industry as filling materials, calcium carbonate is usually mad...

Grinding and drying of bentonite

After crushing and drying mined bentonite, this clay mineral is usually processed through a...

Milling and drying machine for fine powders

When you need to produce ultra-fine powders, the milling and drying process em...

Flash drying grinder for powders

Drying and grinding can be an important feature when trying to process products such as raw...

Horizontal rotary ball mill drum

A horizontal rotary ball mill drum can be used for grinding of dry hard materials, such as ...

Automatic bag slitter

Unacceptably high dust levels can be generated whilst manual emptying and handling of bags, also produc...

Stretch pallet hooder

Palletised loads need to be securely wrapped in order to protect them from shifting, crushing, ripped o...

Vertical form, fill and seal machine for bags from 5 to 50 kg

To securely create, dose and pack larger quantities of mat...

Hygienic FIBC handling line

There are many considerations when handling FIBC’s (Flexible Intermediate Bulk Containers)...

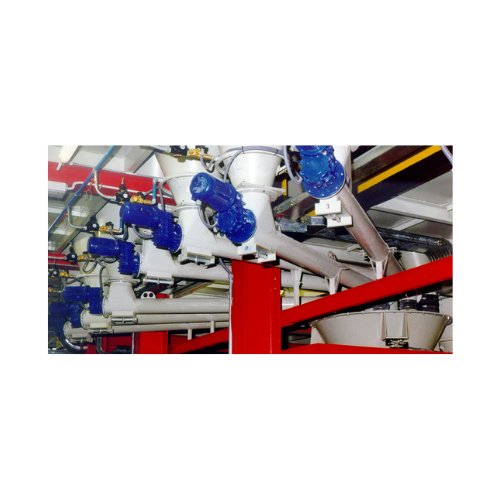

Dual channel plug diverter valve

Short switching times are often required when diverting or combining powder or granular sol...

Two-way flap type diverter valve

Routing powder, pellets or granules from a product source to two receiving points must be d...

High-capacity bulk weighers

A checking weigher recognized for receiving and shipping bulk materials, typically in mills and ...

High-level layer palletizer

A palletizer that meets the middle and high-level needs of modern bagging lines. Quite suitable ...

Versatile open-mouth bagger

If you want highly precise bagger for bagging multiple bag materials, here you go. This versatil...

Hygienic open-mouth bottom-up baggers

Here are the open-mouth baggers that are specially designed for hygienic bagging of p...

Open-mouth bottom-up baggers

Innovative bottom-up baggers for high-speed industrial packaging will help you create a dust-fr...

Circuit-air classifier

For high throughputs, with a fineness range of approx. d97 = 32 µm – 200 µm. Ideal for use in th...

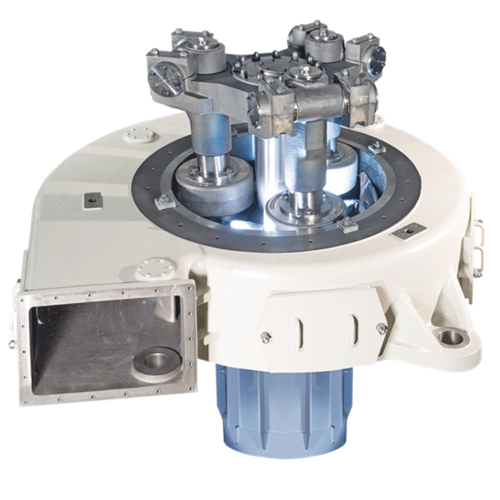

Pelleting press with overhead drive

Production of certain pelletized products requires working with output products of a pa...

Small scale pelleting press

Many industries require reliable pelletizing equipment with smaller scale production capacities....