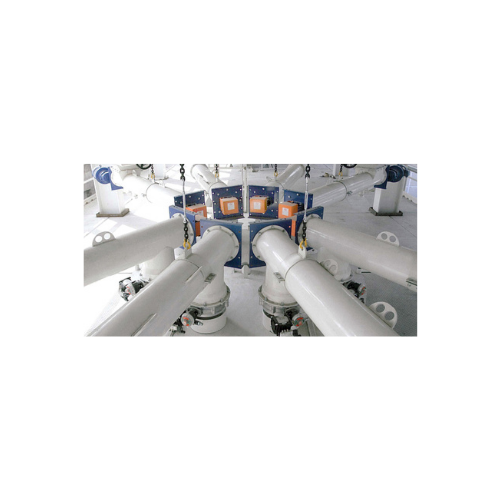

Heavy-duty tubular screw conveyor for bulk solids

Optimize your production line with a durable solution for uninterrupted bulk solids transport, designed to handle a wide range of materials, ensuring longevity and seamless integration into both batch and continuous operations.

Conveys and Processes Bulk Solid Materials

The Heavy-Duty Tubular Screw Conveyor TP-TE from WAMGROUP is engineered for medium to extra heavy-duty industrial applications, particularly in mineral processing, glass manufacturing, and cement production. Constructed from carbon steel with a suitable surface finish, this conveyor features a tubular trough with an inlet and outlet spout, helicoid screw flighting, and adjustable shaft seals, ensuring durability and ease of maintenance. With the ability to handle solid, powder, and granular materials, it supports both batch and continuous operations, integrating seamlessly into existing production lines with its flexible design.

The TP-TE is equipped with a robust gear motor and offers various drive options, such as direct and chain transmission, to optimize performance for different processing needs. Known for coping with demanding environments, it provides reliable service in the transportation of sand, bentonite, and other industrial materials. While not suitable for food applications, it excels in enhancing material flow efficiency, reducing process downtime, and ensuring smooth operation under tough conditions. Customization options include additional spouts, inspection hatches, and rotation indicators, allowing it to meet specific operational requirements.

Benefits

- Ensures consistent material flow, minimizing process interruptions and downtime.

- Supports high-capacity transport requirements, facilitating efficient batch and continuous operation.

- Reduces maintenance costs with durable construction and easy component replacement.

- Customizable design enhances operational flexibility to meet specific industry needs.

- Provides reliable performance in harsh environments, reducing the risk of operational failure.

- Applications

- Lime, Soda, Glass, Bentonite, Gypsum, Sand, Minerals, Foundry materials, Calcium carbonate, Cement

- End products

- Glass beads, Foundry molds, Wallboard, Silica sand, Portland cement, Bentonite clay, Limestone filler, Soda ash, Quicklime, Plaster

- Steps before

- Crushing, Grinding, Micronizing, Material Mixing

- Steps after

- Packing, Silo Storage, Batch Mixing, Material Handling

- Input ingredients

- minerals, glass, cement, gypsum, lime, silica fume, sand, bentonite, calcium carbonate, soda, filler dust, plasters, additives

- Output ingredients

- conveyed minerals, processed glass, conveyed cement, gypsum products, lime products, conveyed silica fume, conveyed sand, bentonite products, conveyed calcium carbonate, conveyed soda, processed filler dust, processed plasters, conveyed additives

- Market info

- WAMGROUP is known for its expertise in manufacturing bulk material handling and processing equipment, including screw conveyors, dust collectors, and valve systems, with a strong reputation for innovation, quality, and global market presence.

- Material

- Carbon steel with suitable surface finishing

- Type

- Medium and extra heavy-duty (TP/TE)

- Operation Mode

- Batch and Continuous

- Power Transmission

- Gear motor

- Additional power transmission

- Screw Flighting

- Helicoid, welded on a center pipe

- Bearing Assemblies

- End bearing assemblies with adjustable shaft seal

- Inlet/Outlet

- At least one of each

- Coupling

- Bush (TP) or Flanged (TE)

- Durability

- Medium to extra heavy-duty

- Batch vs. continuous operation

- Batch / Continuous

- Replacement ease

- Easy component replacement

- Suitable for tough conditions

- Yes, reliable in tough conditions

- Power transmission

- Gear motor with additional transmission

- Local service support

- Available through WAM subsidiaries

- Abrasion resistance

- Yes

- Corrosive resistance (e.g. acids)

- Carbon steel with surface finishing

- Density/particle size

- Variable (e.g., minerals, sand, cement)

- Cleanability

- No special features for cleanability

- Tubular trough

- Yes

- Helicoid screw flighting

- Welded on a center pipe

- End plate flanged on each tube end

- Yes

- Multiple inlet and outlet spouts available

- Vast selection

- External tube supports

- Optional

- Screw (auger) design options

- Different design features available

- Control panel type

- Manual / PLC / HMI

- Drive options

- Direct with or without semi-elastic shaft transmission coupling, chain transmission, belt transmission

- Additional inlet / outlet spouts

- Customizable

- External tube supports

- Available

- Trough feet

- Available

- Inspection hatches

- Additional inspection hatches available