Making Wine

Find innovative production technology for making wine and connect directly with world-leading specialists

The winemaking process starts with harvesting and crushing grapes, goes through fermentation, ageing and finishes with packaging. Winemaking supplies vary according to the desired wine and the production or plant size.

Select your wine process

Tell us about your production challenge

First procedures for making wine: picking grapes

The harvesting process begins with winegrowers manually picking up grapes. It may also happen with harvesting machines, which speed up the process. They function as a usual tractor but with vibrating “arms” that pick the grapes and put them on a carpet. There, the equipment removes insects and branches. Some wine varieties are more difficult to harvest with machinery due to the fragility of the berries.

Winemaking supplies to extract juice out of grapes

While you can experience stomping grapes in some wine festivals or vineyards around the world, machines usually do the maceration work. Crushers can be combined with a destemmer, which opens the grapes to get their juice. They also separate the fruit from the steam, as the name suggests. In this phase, grape juice gets in contact with grape skins – in the case of red and rosé wines, at least. White wines usually cannot have contact with the skins, as if affects their sweet taste.

Choosing winemaking equipment for fermentation and ageing

Fermentation is the next step in the winemaking process, and vessels change according to what you seek in your wine. It can be either a stainless steel, wood or concrete container, or even an amphora jar. The choice affects the fermentation temperature, which is harder to control depending on the material. White wines ferment under lower temperatures than red ones because the cold helps maintain their fruity flavors and colors. Either way, fermentation at low temperatures helps extract a more flavory taste out of the wine.

After fermentation, the wine goes to a tank or barrel, where it ages. Maturation develops complex aromas and smoother tastes. The next step is to bottle the aged wine.

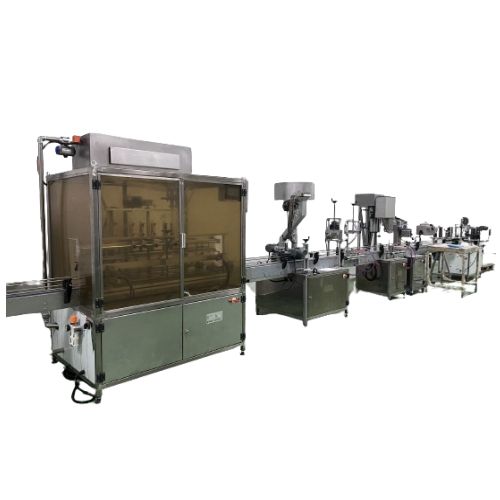

Bottling and packaging winemaking supplies

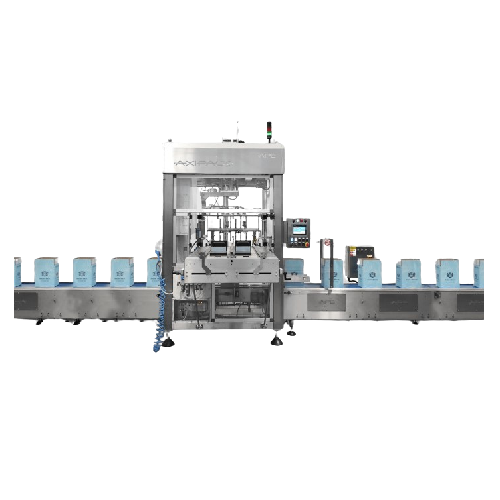

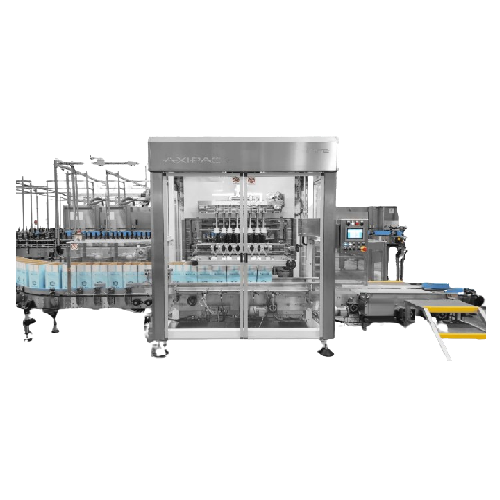

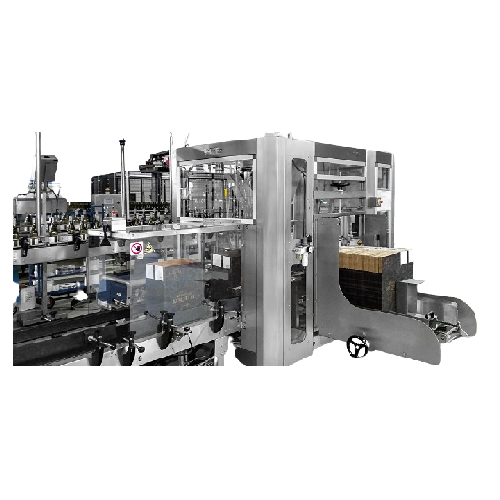

You may choose between semiautomatic and automatic machines that will pump your wine into the bottles. They can be adjusted with the maximum level of liquid you want in the bottle and their systems discard damaged bottles. After bottling, sterilization is an essential step to reduce the chances of contamination. Once cleaned, you can pack the wine bottles.

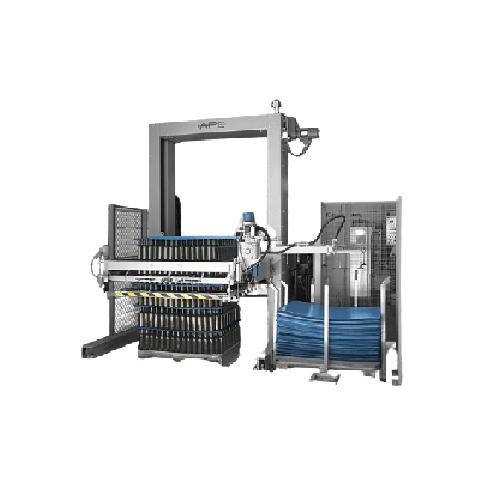

You can choose different winemaking supplies for packaging. One possibility is to opt for cartons with partitions, for instance, to avoid damaging the bottles. You can find both preformed partitions and non-preformed partitions; have in mind that the latter saves costs and still protects your bottles from crashing against each other. The packaging process of wrapping the bottles can be automated from the very opening of the carton.

Which wine technology do you need?

Separators for biochemicals

Achieve precise separation and purification of complex biochemical mixtures with self-cleaning c...

Clarifier for beverages

Enhance beverage clarity and purity with high-performance centrifugal separation, expertly designed t...

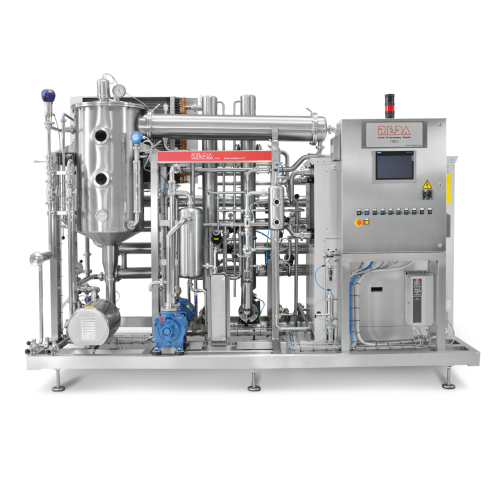

Uht sterilization for drinkable milk

Ensure long shelf-life and food safety without compromising the natural qualities of y...

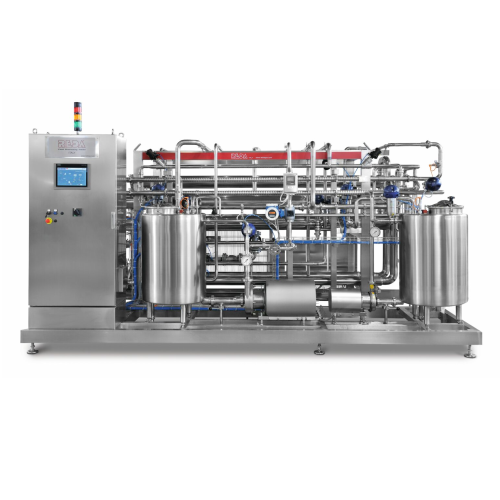

Pasteurizer for extended shelf-life (esl) milk

Extend the shelf life of milk while maintaining its taste and nutritional i...

Wine clarification system

Enhance your wine production by effectively removing unwanted solids and reducing oxidation risk, ...

Milk pasteurizer for whey and cream

Ensure optimal product safety and quality with advanced heat exchange technology, reduc...

Whey processing line

Streamline whey processing by transforming byproducts into high-value proteins, catering to diverse nutr...

Milk collection system for bulk tankers

Optimize milk transfer and storage with a reliable system that reduces discharge ti...

Milk skimming separators for dairy applications

Enhance dairy production with high-efficiency skimming separators that opt...

Milk standardization system

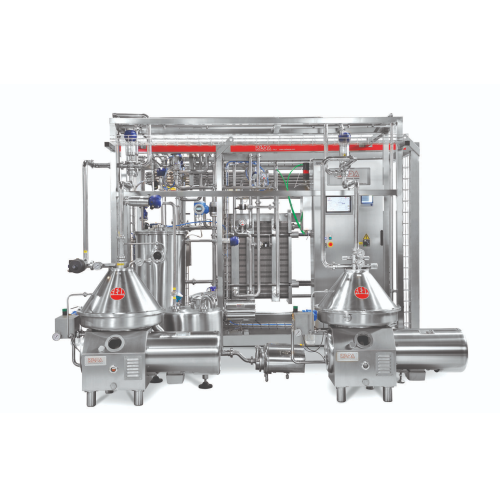

Achieve precise milk and cream fat standardization with this advanced inline system, optimizing ...

Pasteurizer for fresh milk

Ensure your dairy and beverage lines achieve optimal product safety and quality by leveraging adv...

Grape must concentration solution

Optimize the alcohol content and flavor profile of your wines by efficiently concentratin...

Membrane filtration for whey concentration

Enhance your liquid processing with advanced membrane filtration designed to im...

Blending and mixing unit for dairy and beverages

Achieve precise recipe control and high-quality results by seamlessly int...

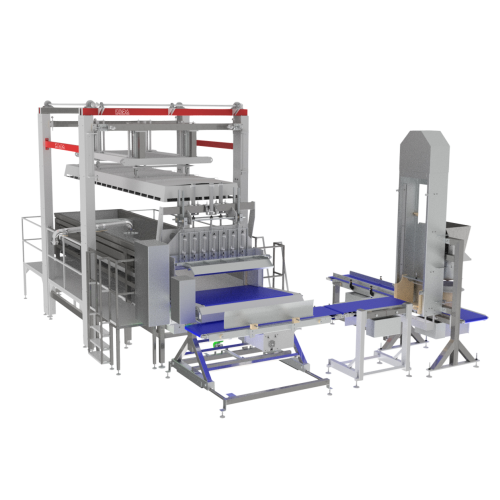

Cheese forming units for hard and semi-hard cheeses

Optimize your cheese production process with advanced moulding and pr...

Low temperature evaporator for heat-sensitive food products

Efficiently concentrate sensitive liquid products while pres...

Wine dealcoholization system for low-alcohol wines

Struggling to meet market demands for low-alcohol wines? Achieve preci...

Milk evaporator for dairy industry

Optimize your liquid food production with precise control over evaporation processes, en...

Vacuum deaeration with aroma recovery for juices

Eliminate oxygen from liquid foods to prevent oxidation while retaining v...

Fermentation tank for yoghurt and fermented dairy products

Optimize your dairy and plant-based drink production with eff...

Bacteria removal separator for dairy products

Ensure top-quality dairy and plant-based products with reliable bacteria rem...

Brine purification system for reducing bacteria and molds

Ensure pristine brine quality by continuously removing bacteri...

Clarifier for milk and whey

Optimize dairy and beverage production by efficiently removing fine curd residuals, ensuring hig...

Juice clarification system

Ensure consistent beverage clarity with advanced separation technologies, enhancing production ef...

Curd making equipment for cheese production

Optimize your cheese production with versatile curd making equipment, designed...

Aseptic tank for sterile liquid food storage

Ensure sterility and maximize shelf life for liquid foods by utilizing an ase...

Uht sterilization for milk

Enhance your production line with advanced UHT sterilization, ensuring extended shelf-life and un...

Complete milk processing lines

Optimize liquid product quality with a comprehensive processing line that integrates pasteuri...

Centrifugal pumps for food & beverage and biopharmaceutical applications

Optimize your liquid transfer processes with p...

Aseptic sampling devices for biopharmaceutical applications

Secure aseptic sampling ensures your high-value biopharmaceu...

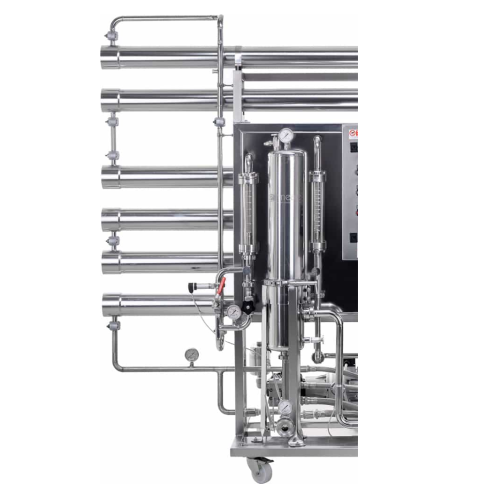

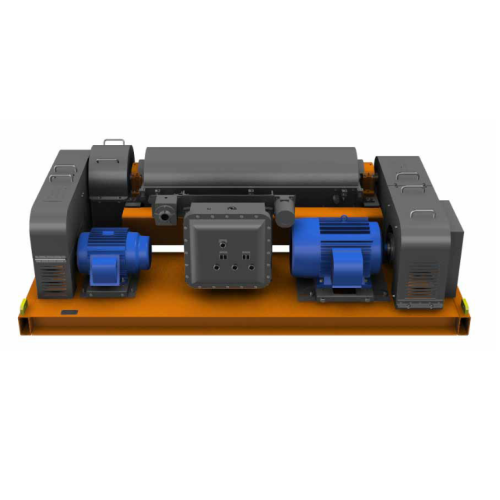

Mobile cleaning-in-place unit for process equipment

Ensure seamless cleaning of diverse process equipment with a mobile, ...

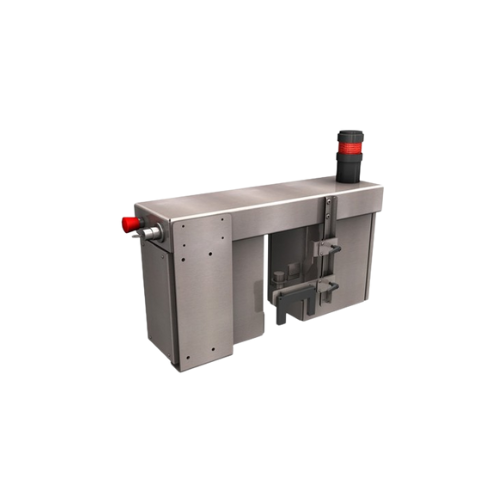

Compact cleaning in place units for food industry

Optimize your production line with a compact system designed for effici...

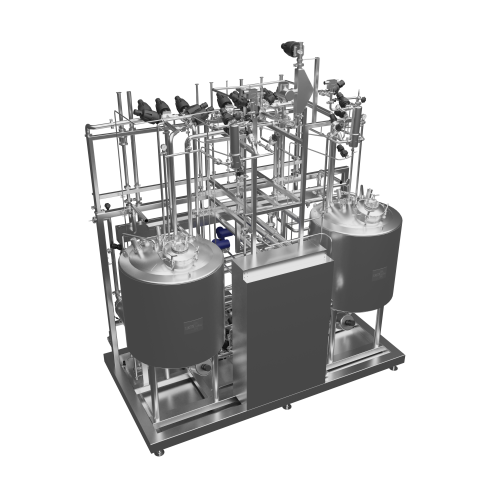

Cleaning-in-place for multiple equipment in food industry

Ensure precise hygiene and traceability with a system designed...

Industrial agitation and mixing solutions

Enhance your production line efficiency with engineered agitation and mixing sys...

Cleaning and sterilization in place for hygienic control

Ensure maximum hygiene and sterility in your production line wit...

Stainless steel process vessels for biopharmaceutical applications

Ensure seamless mixing and sterilization with engine...

Automation for food processing

Optimize your food production with cutting-edge automation, enhancing efficiency and precisio...

Batch processing systems for industrial applications

Optimize batch production with versatile systems that enhance energy...

Cip cleaning systems for food and beverage industry

Optimize your cleaning operations with seamless Clean-in-Place and St...

Inline processing system for food and beverage production

Optimize your production line with a versatile inline processi...

Industrial premixing system for batch and inline processing

Streamline your production with advanced premixing systems d...

Turnkey food and beverage processing solutions

Optimize your production line with integrated processing systems designed t...

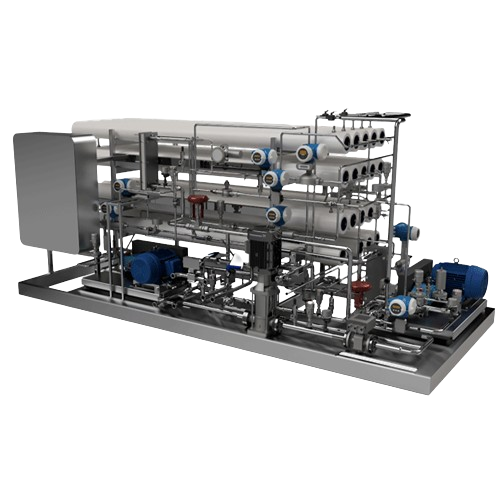

Reverse osmosis for concentration of oenological products

Enhance your winemaking process by concentrating and enriching...

Tangential filtration system for wine production

Achieve precise filtration, purification, and concentration of compounds ...

Tangential filtration system for wine clarification and stabilization

Ensure product quality and efficient bottling pre...

Close proximity cleaning-in-place solution for industrial hygiene

Enhance plant hygiene with a close proximity cleaning...

Automatic filtration system for beverage industry

Enhance your beverage production with a multi-stage filtration system t...

Clean-in-place system for industrial cleaning needs

Optimize your production efficiency with a system that seamlessly int...

Industrial cooling vessel for ready meal components

Enhance your production with precise cooling and gentle handling of t...

Mayonnaise production system

Ensure precise emulsification for low to full-fat mayonnaise and similar cold emulsions with a ...

Aseptic storage tanks for high efficiency applications

Ensure consistent aseptic storage and efficient handling of variou...

Compact production unit for liquid food products with varied viscosities

Streamline your batch production with this ver...

Scraped surface heat exchanger for food processing

Efficiently handle temperature-sensitive food products with a compact ...

Pig systems for product recovery in food and beverage industry

Maximize yield and minimize waste with advanced PIG syste...

Hygienic fluid storage tanks for food industry

Ensure impeccable hygiene in fluid storage with our customizable tanks, des...

Aseptic thermal processor for high viscosity products

Optimize your processing of high viscosity products with precise te...

Ped tested filtration system for sparkling wines

Ensure consistent carbonation and clarity in your sparkling beverages wit...

Nanofiltration and reverse osmosis for wine processing

Streamline your beverage production by effectively concentrating l...

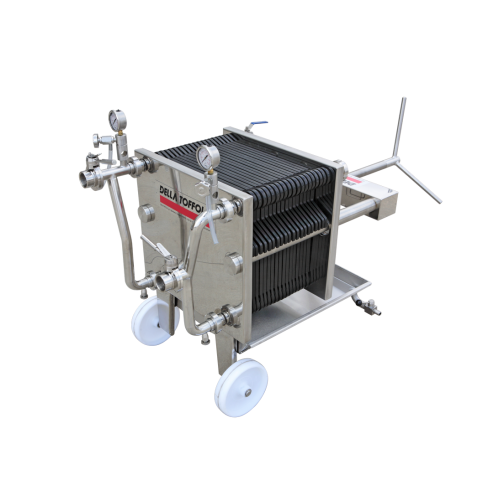

Plate and sheet filter for wine and vinegar

Optimize the filtration of liquids like wine and vinegar with this versatile s...

Plate flash pasteurizer for wine

Ensure optimal microbial inactivation while maintaining product quality with high-efficienc...

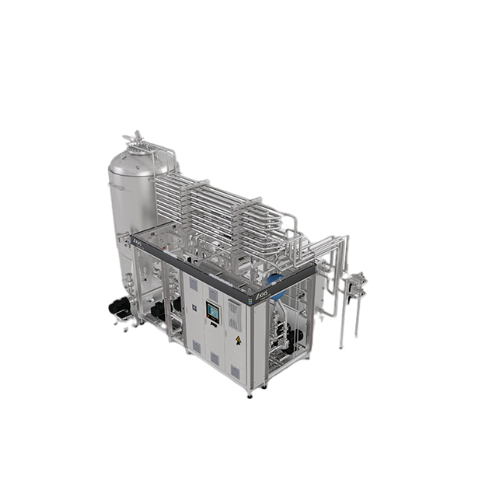

Tubular pasteurizer for wine, grape juice, and dairy

Ensure product integrity by efficiently inactivating microorganisms ...

Premix system for alcoholic beverage preparation

Enhance your beverage production with precision mixing and carbonation, e...

Cylindrical-conical tanks for yeast propagation in wine and grape juice

Optimize your fermentation process with efficie...

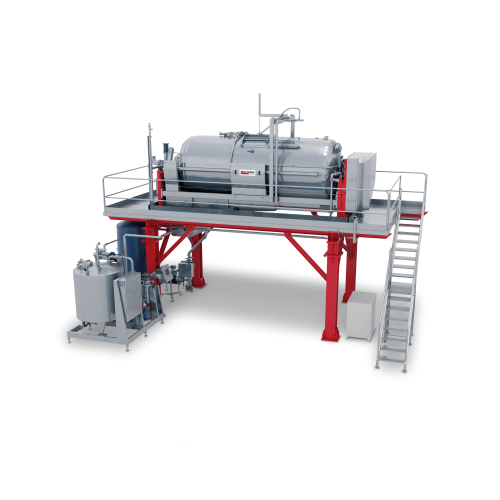

Thermovinification plant for grape juice

Optimize color and tannin extraction while reducing energy use by up to 35% with t...

Continuous flotation unit for grape juice

Efficiently separate solids from liquids in grape and fruit juice production, ac...

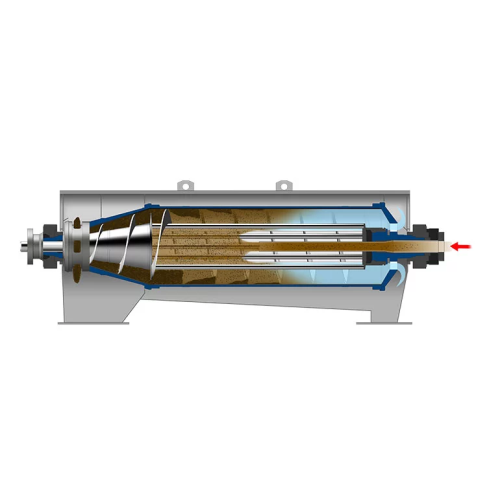

Rotary drum vacuum filter for wine lees

Optimize your filtration process for products like wine lees and sweeteners with ou...

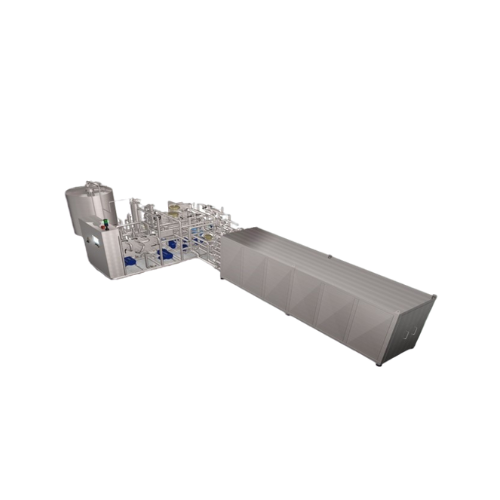

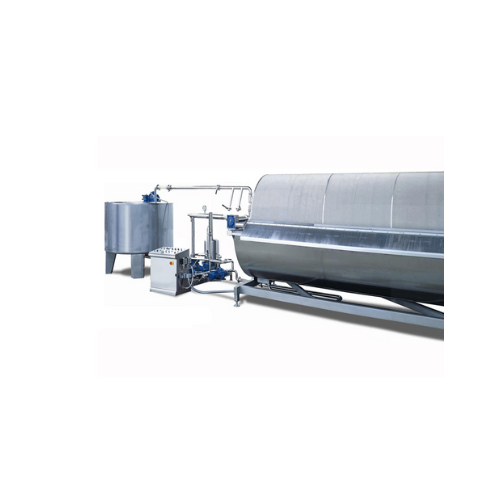

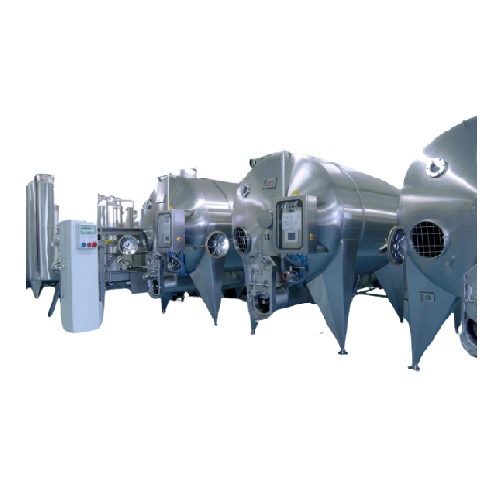

Tunnel pasteurizer for wine

Optimize your wine production with a high-efficiency tunnel pasteurizer, designed to enhance pro...

Scraped surface ultra cooler for liquid temperature reduction

Optimize your liquid cooling processes with advanced heat ...

Cip system for wine, grape juice, oil, and dairy

Ensure optimal hygiene and operational efficiency in processing lines wit...

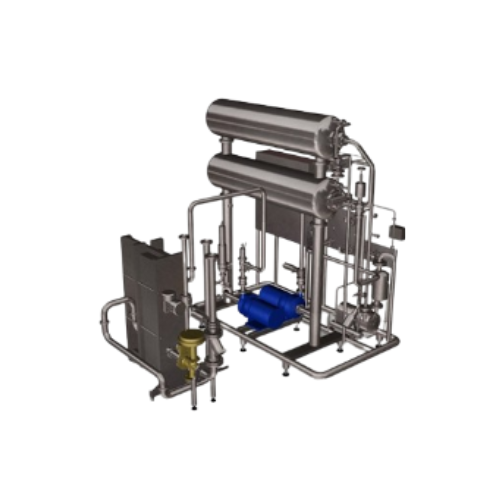

Fermentation temperature control for wine production

Ensure precise fermentation with advanced temperature control, cruci...

Crossflow filter for wine and grape juice

Efficiently streamline your beverage filtration process with a versatile crossfl...

Desulphurizer for grape juice

Eliminate sulfur dioxide vapor release while preserving juice concentration, achieving purity ...

High solids crossflow filter for wine filtration

Optimize filtration efficiency while minimizing operational costs with th...

Crossflow filter for wine production

Optimize your wine and juice production with advanced membrane filtration, ensuring hi...

Horizontal plates d.e. filter for wine and vinegar

Optimize filtration and purification across liquids with precision, en...

Continuous tartaric stabilisation for wine

Ensure your wines are free from unwanted crystals with a continuous solution th...

Vertical leaves pressure filter for wine and viscous liquids

Ensure optimal clarity and consistency in your liquid produ...

Ion exchange system for wine and grape juice stabilization

Enhance wine and grape juice quality by achieving consistent ...

Wine carbonator with static mixer

Achieve precise CO2 saturation with a sintered stainless steel static mixer, mimicking a ...

Batch food processing cookers

Achieve precise temperature and pressure control for small-scale food production with modular ...

Small-scale scraped surface heat exchanger for high-viscosity products

For R&D teams tackling complex formulations...

Direct steam injection Uht pilot system

Elevate your production capabilities with a sanitary UHT pilot system designed for ...

Lab-scale high-pressure homogenization solution

Optimize your lab-scale production with precision homogenization, ensuring...

Pilot homogenizer for high-pressure inline homogenization

Achieve precise homogenization and emulsification across vario...

Manual Cip unit for lab and pilot plant cleaning

Need thorough cleaning without disassembling your pilot plant? This compa...

Wine washing system for bottling quality control

Ensure pristine wine quality by eliminating waste through innovative bott...

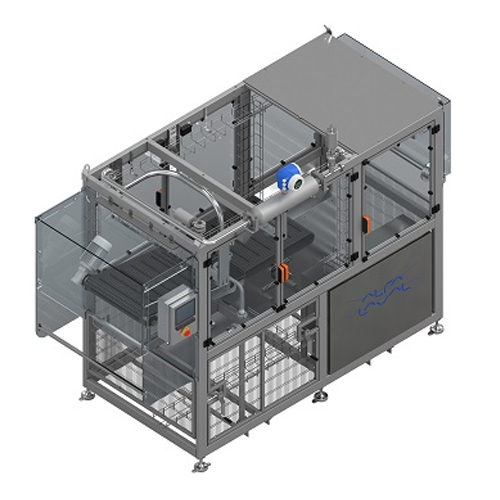

Automated case erector for Rsc cartonboard

Streamline your packaging line with an innovative solution that efficiently for...

Automatic case erector for Rsc-american cartonboard

Streamline your packaging process with precise and efficient setup by...

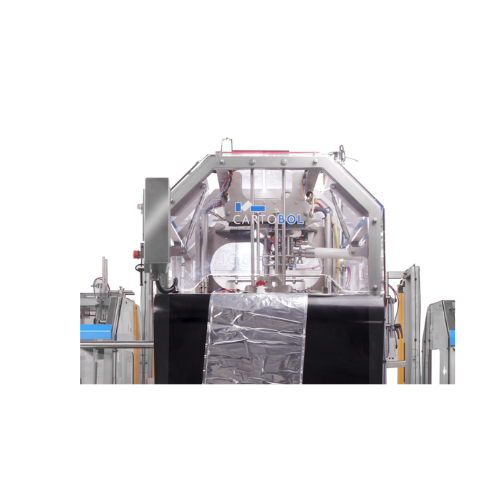

Automatic case erector for cartonboard with hot-melt glue binding

Streamline your packaging line with efficient case er...

Unpacker for return bottles

Effortlessly manage return bottle operations with high-speed unpacking solutions that ensure pre...

Automated carton former for Rsc american boxes

Streamline your packaging line with high-speed carton forming that combines...

Automated carton forming for bottles

Optimize your bottling line with an integrated carton forming solution that combines s...

Automatic carton erector with hot glue sealing

Streamline your packaging line with precision carton forming and sealing, e...

Automated bottle packaging solution for breweries

Streamline your packaging process with a compact unit that combines bas...

Depalletisers for high-capacity bottle handling

Streamline your bottling line with a versatile depalletising system design...

Flexible depalletizers for bottling lines

Streamline your packaging operations with a compact depalletizing solution desig...

Automated case erector for high-speed packaging lines

Streamline your packaging line with this solution that forms and se...

Automatic palletizer for bottle packaging lines

Streamline your bottling line with advanced palletizing solutions engineer...

Bottle repacking system for return cartons

Optimize your bottle repacking efficiency with a system designed specifically f...

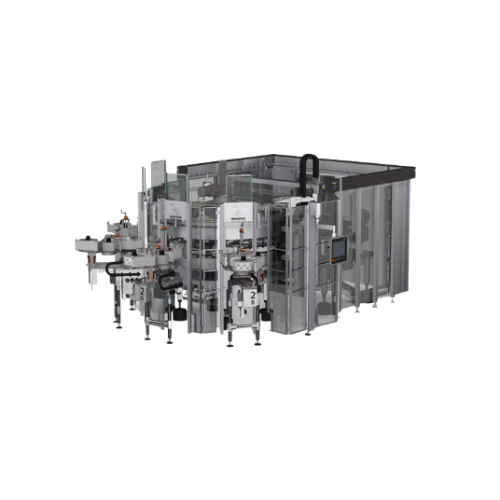

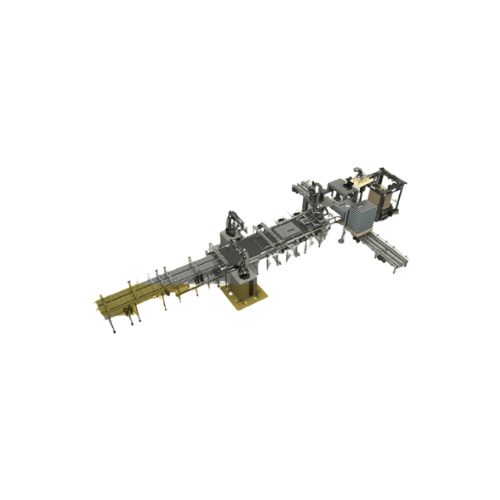

Automated packaging line for bottling industry

Streamline your packaging operations with a fully automated solution design...

Automated case erector for american cases

Streamline your packaging line by efficiently erecting American-style cases with...

Automatic bag-in-box packaging system

Optimize your liquid packaging with a precise and seamless workflow, ensuring efficie...

Advanced case erector for Rsc/american cartonboard

Optimize your packaging line with precise case erection and glue seali...

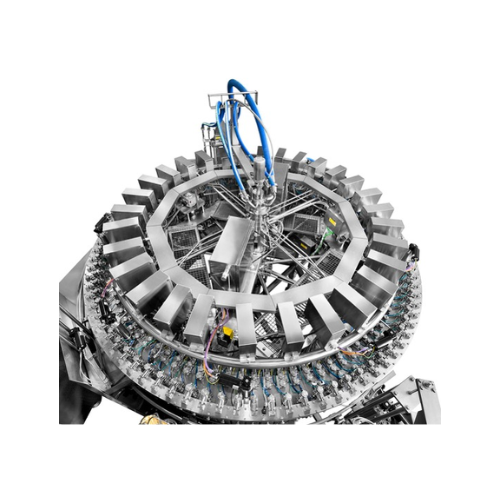

Automatic labelling system for champagne bottles

Enhance your production line with a high-speed labelling solution that en...

Monoblock capsuling solution for bottles

Streamline your bottling process with this high-speed capsuling machine, deliverin...

Rotary labeling solution for bottles and containers

Optimize your labeling process with high-speed precision, handling va...

Semiautomatic labelling solution for cylindrical bottles

Effortlessly apply precise labels to various cylindrical and squ...

Robotic crating and decrating solution for returnable glass bottles

Streamline your bottling line by efficiently handli...

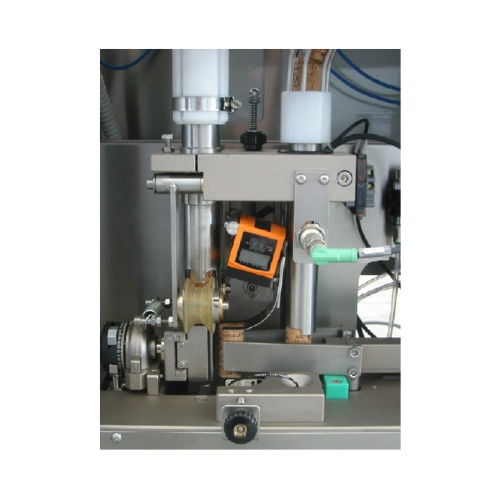

Optical recognition system for cork marking alignment

Ensure precise cork placement and quality in wine bottling with a s...

Heavy-duty palletizing robot for production lines

Effortlessly streamline your production with this robust palletizing ro...

Flash pasteuriser for beer

Ensure superior beverage quality with precise pasteurisation and carbonation while minimising ene...

Wine filtration system

Achieve crystal-clear wines and sparkling beverages by efficiently removing suspended particles and mi...

Crate washer for beverage manufacturers

Ensure thorough cleaning of beverage crates with an advanced washing system featuri...

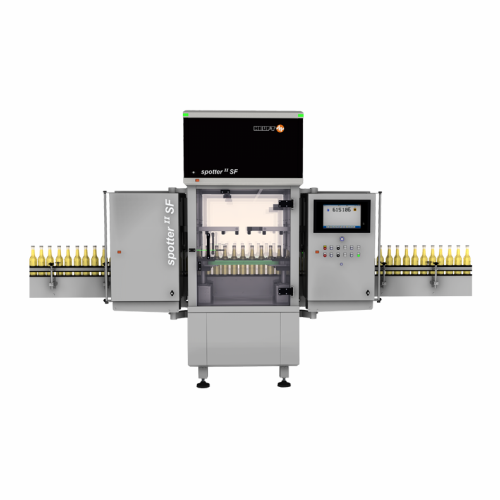

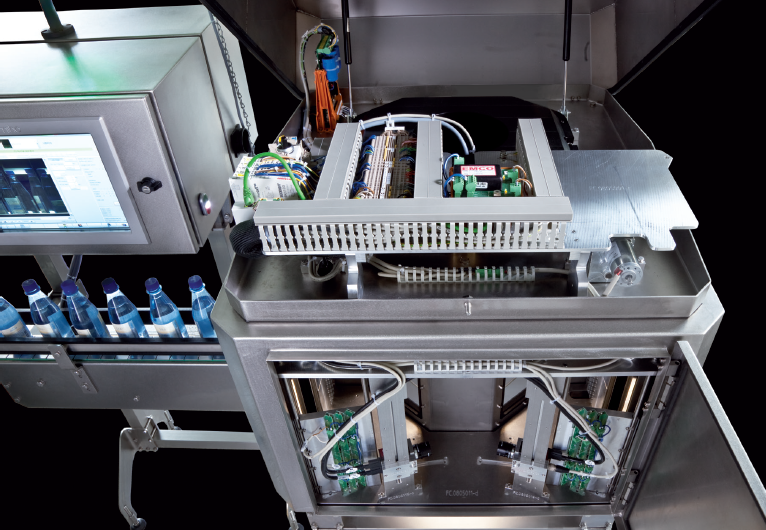

Bottle inspection system for foreign particles detection

Ensure your beverage products remain uncontaminated with high-pr...

Low output can filler for craft beer

For beverage producers looking to efficiently fill cans with precision, this versatile...

Wine and beer clarification system

Achieve superior clarity and stability in your wine and beer production, eliminating sus...

Mbr module for wastewater treatment

Optimize your wastewater management with efficient membrane bioreactors, designed to en...

Flexible labeling system for returnable and non-returnable containers

Achieve precise labeling and enhanced alignment w...

Self-adhesive labeling for glass and Pet bottles and beverage cans

Maximize your production efficiency with a labeling ...

Flexible packaging system for beverage containers

Streamline your packaging process with a modular system that adapts sea...

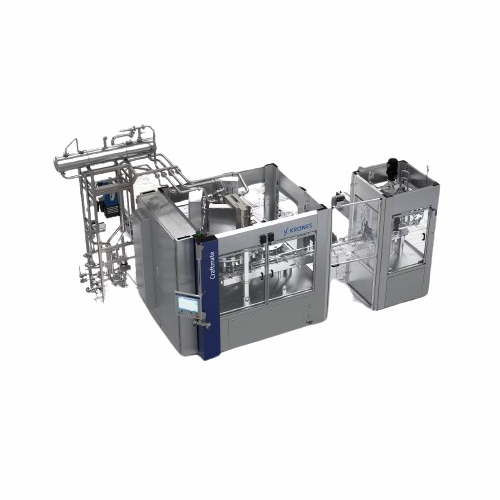

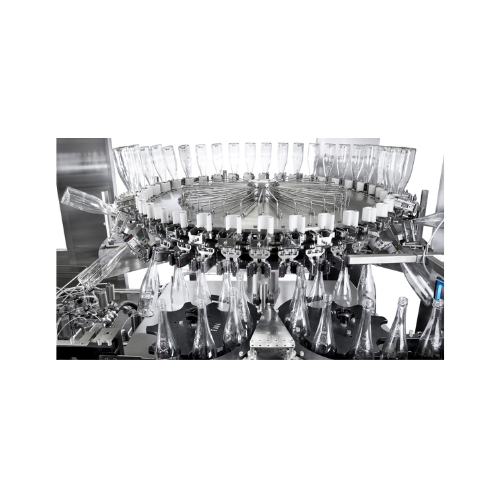

Wine and sparking wine filling system

Achieve precise filling and minimal oxygen pickup for high-value beverages with a rel...

Enclosed film packaging solution

Eliminate the need for corrugated trays and minimize packaging waste with a robust solution...

Bright beer tank cellar for beer storage

Enhance your beverage production efficiency with a fully automated solution that m...

Water deaerator for beverage production

Enhance the quality and extend the shelf life of your beverages with our cutting-ed...

Filter system for beverage stabilization and clarification

Ensure your beverages are crystal clear and stable with a ver...

Energy-efficient hot filling system for beverages

Optimize your beverage filling processes with a system that ensures pre...

Blending system for fine adjustment of original gravity in beer

Ensure precise control over your beer’s original gravity...

Continuous flash pasteurizer for beverage shelf life extension

Maximize beverage shelf life with precise microbial and e...

Blending system for deaeration and carbonation of beverages

Achieve precise blending, efficient deaeration, and accurate...

Stretch blow molding with integrated coating for Pet bottles

Enhance product longevity and quality by integrating stretc...

Pet bottle stretch blow molding with coating and filling

Extend the shelf life of your beverages and liquid products with...

Transparent glass barrier coating for Pet bottles

Ensure the longevity of sensitive beverages and liquid foods with glass...

Carbonating solution for precise Co2 content in beverages

Enhance your beverage production with seamless CO2 integration...

Compact cleaning system in container format

Optimize your production lines with a space-saving cleaning system capable of ...

Cip cleaning system for food and beverage production lines

Ensure microbiological safety and maintain quality standards ...

Dosing and blending system for beverage production

Enhance your beverage production with a flexible system capable of pre...

Multifunctional filter system for beverages and gases

Achieve precise filtration across multiple beverage and gas mediums...

High-performance palletizer for cans, Pet, and glass containers

Elevate your palletizing efficiency with cutting-edge ro...

High-performance distribution and combining system

Streamline your packaging operations with a versatile system designed ...

Robotic layer grouping system for container distribution

Streamline your packaging line with precise, high-speed containe...

360° palletizing and depalletizing robot

Optimize your packaging flow with a robot offering seamless 360° operation for pre...

180° palletizing robot for automated palletizing and depalletizing

Optimize your production line with a versatile solut...

Flexible tunnel pasteurizer for beverage sterilization

Maximize product safety and flexibility in your production line wi...

Pet bottle filler for hot and cold still beverages

Achieve high-speed precision in filling and capping for various bevera...

Modular labeling system for beverage containers

Easily adapt to evolving labeling needs with this flexible system, designe...

Gentle container conveyor for bottles and cans

Achieve seamless container flow with minimal noise and enhanced precision, ...

Multifunctional packing system for beverage containers

Maximize your facility’s packing efficiency with a versatile...

Packer and unpacker for returnable and non-returnable containers

Streamline your packaging line with a versatile machine...

Depalletizer with accurate level compensation

Optimize your high-speed assembly line with a depalletizer designed for prec...

High-speed beverage industry palletizer

Optimize your palletizing process with a flexible, high-speed solution that adapts ...

Closure inspection system for crown corks and metal caps

Ensure product integrity with high-speed 360° closure inspection...

Industrial code verification system for product packaging

Ensure flawless packaging integrity with high-speed code verif...

High-precision fill level checker for beverages and containers

Ensure precise fill levels and prevent product wastage by...

Rejection system for standing bottles and cans

Ensure seamless quality control by precisely rejecting defective bottles an...

Label inspector for beverage and food containers

Ensure precise label application with high-speed inspection, crucial for ...

Pallet inspection system

Ensure the stability and integrity of diverse pallets with a high-speed inspection system that minim...

Container rejection system for high-speed operations

Ensure product safety by swiftly removing defective containers at hi...

Bottle filler for beer and soft drinks in glass bottles

Achieve precision in bottling with reduced CO2 emissions and low ...

Pvpp beer stabilization system for breweries

Reduce beer hazing and extend shelf life with this advanced stabilization sys...

Crossflow filter for liquid filtration in food industry

Enhance your liquid filtration process with a versatile crossflow...

Horizontal element kieselgur filters

Enhance your production with a filtration system that ensures effective separation of ...

Am less filter for wine and industrial fluids

Streamline your fluid processing with a multifunctional filter designed to h...

Industrial sheet filter for liquid filtration

Optimize your liquid product purity with precise filtration, maintaining int...

Vacuum rotary filter for liquid filtration

Enhance your production line’s efficiency with precise filtration, ensuri...

Centrifugal separators for dairy products

Enhance your liquid food product quality with centrifugal separators designed fo...

Wine tank agitator for homogeneous mixing

Achieve precise mixing and uniform temperature distribution in your wine product...

Oxygen and carbon dioxide monitoring and elimination system

Achieve precise control over dissolved gases with a system t...

In-line additive dosing systems for beverages

Ensure precision and safety in beverage production by integrating in-line do...

Piping discharge system for product separation in transfer lines

Optimize your beverage production by preventing product...

Micro-filtration system for beverage industry

Achieve microbiological stability at cold temperatures with our micro-filtra...

Powder mixing system for beverage industry

Enhance your beverage production with an advanced powder mixing system that ens...

Wine recovery system for bottling processes

Streamline bottling operations by recovering and re-dosing valuable wine, redu...

Co2 dosing system for effervescent beverage bottling

For beverage manufacturers requiring precise carbonation, this solut...

Automated system for cleaning in place (cip)

Ensure thorough, efficient cleaning of your production equipment with a syste...

Top loading case packer for loose or bundled bottles

Effortlessly handle and pack both standard and uniquely shaped bottl...

Full container inspection for glass and Pet bottles

Ensure the highest product quality by detecting foreign objects and m...

Closure inspection for beverage containers

Ensure the integrity of your bottled products with precision closure inspection...

Semi-modular labeller for precise beverage bottle labelling

Achieve millimeter-precision bottle labelling with seamless ...

X-ray assisted empty bottle inspection

Enhance your production line with advanced X-ray and optical technology to ensure pr...

Fill level and closure inspection system

Ensure precise fill levels and secure closures in high-speed liquid packaging envi...

Advanced foreign object inspection for full beverage containers

Ensure consumer safety and brand protection with advance...

Full case check for beverage production lines

Ensure complete packaging integrity by detecting and removing cases with mis...

Conveyor control system for beverage filling lines

Optimize your production line’s efficiency by seamlessly managin...

Empty bottle inspection for beverages

Ensure high quality control and prevent contamination in beverage production lines wi...

Grape harvest cooling tunnel

Ensure optimal grape quality for winemaking by precisely controlling temperature with a mobile ...

Mobile stainless steel tank for grape harvest transfer

Facilitate efficient grape harvest transfer with a motorized mobil...

Thermal treatment units for wine processing

Optimize your wine and spirits production with precise temperature control, en...

Stainless steel tanks for winemaking

Optimize fermentation with precise temperature control and insulation, ensuring the pe...

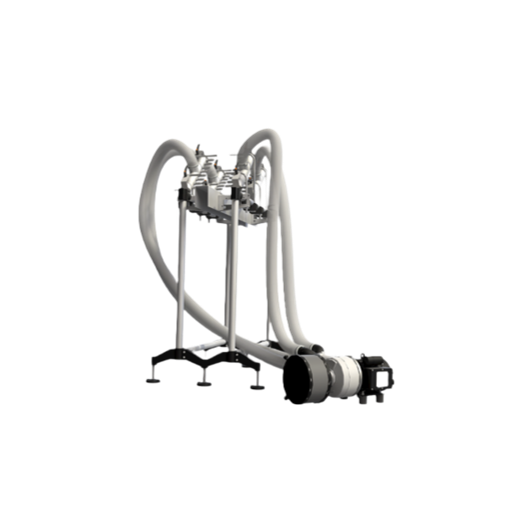

Automated pumping over system for red wine vinification

Enhance your red wine fermentation process with a compact solutio...

Vertical red wine tank

Optimize red wine production with a system that seamlessly integrates traditional winemaking technique...

Vertical red winemaking tanks

Streamline your red wine vinification with advanced vertical tanks that optimize oxygen manage...

Fermentation monitor for alcohol production

Optimize anaerobic yeast fermentations with precise monitoring of carbon conve...

Complete bottling lines for beverage industries

Optimize your bottling process with high-speed, precision-engineered lines...

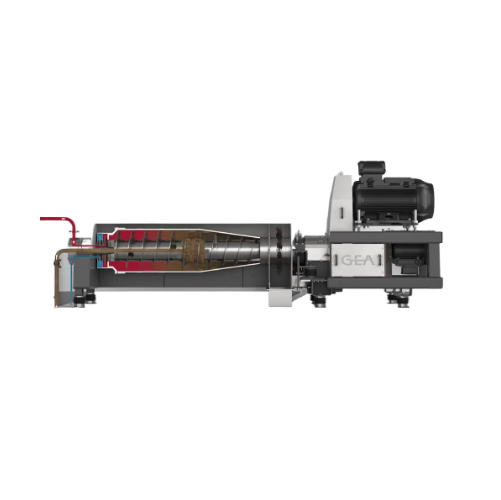

Decanter centrifuge for soft sediment separation

For operations dealing with soft, easy-flowing sediments, ensuring effici...

2-phase separator for clarifying liquids

Efficiently refine and clarify liquids while minimizing waste. This 2-phase separa...

Industrial belt press for fruit and vegetable processing

Optimize your juice yield and reduce drying costs in starch and ...

Advanced sludge dewatering for sewage treatment plants

Optimize sludge dewatering with a centrifuge that enhances separat...

Ultra hygienic filler for non-aseptic products

Optimize your production with high-speed filling and sealing of liquid prod...

Winemaking tanks and autoclaves

Optimize your fermentation process with customizable tanks that integrate seamlessly into yo...

Fermenter for microbial fermentation processes

Optimize your fermentation and biopharmaceutical production with stainless ...

Liquid food filling solutions

Maximize efficiency in your packaging line with versatile filling machines designed for precis...

Conical powder mixer for uniform powder blending

Achieve consistent powder blending while preserving the integrity of deli...

Stainless steel fermentation tanks

Optimize your fermentation efficiency with stainless steel tanks that provide precise te...

Ultraclean aseptic storage tanks for hygienic liquid food

Ensure your liquid products remain uncontaminated and maintain...

Automated cleaning in place (cip) systems for beverage processing

Optimize your production with automated CIP systems t...

Pulsed electric field system for olive oil processing

Enhance extraction efficiency and product quality with this advance...

Compact pulsed electric field treatment for french fries

Reduce oil absorption and enhance product texture with this inno...

Pulsed electric field treatment for roots, tubers, and fruits

Enhance your production line with advanced pulsed electric...

Cell disintegration measurement tool for food products

Ensure precise measurement of cell disintegration across food prod...

Modular pulsed electric field system for food processing

Enhance your food processing efficiency with a modular system th...

Precision quality control for potato and vegetable cutting

Optimize cutting precision and improve product quality by ins...

Crossflow filtration with ceramic membranes for wines

Enhance filtration efficiency and durability with ceramic membranes...

Rotary vacuum filters for wine and lees filtration

Achieve high-precision liquid filtration and separation with continuou...

Rotary vacuum filters for wine and beverage filtration

Efficiently filter and clarify wines, juices, and industrial fluid...

Industrial sheet filters for diverse liquid filtration applications

Achieve precise liquid filtration with adaptable sh...

Wine stabilization using resin skid systems

Achieve precise wine stabilization by reducing tartaric acid and potassium lev...

Pneumatic presses for wine production with open tanks

Optimize your wine production with presses designed to maximize str...

Presses compensated with inert gas for winemaking

Ensure the protection of delicate wine flavors during pressing by utili...

Wine presses with closed tanks for red and rosé wines

Optimize your winemaking process with presses designed for gentle e...

Fully automatic continuous flow wine press

For winemakers seeking to optimize operations, this advanced pneumatic pressing...

Thermovinification system for red grapes

Enhance your red wine production by rapidly extracting rich color and flavor compo...

Thermovinification system for red wine production

Optimize your vinification process with a complete thermovinification s...

Industrial crossflow filters with ceramic membranes

Achieve precise filtration with robust ceramic membranes, ideal for h...

Crossflow filter for clarified and unclarified wines

Optimize your filtration process with ceramic membrane technology th...

Ceramic membrane crossflow filters for wine clarification

Enhance filtration efficiency with ceramic membranes offering ...

Kieselgur filter for wine and lees

Enhance clarity and purity in your beverage filtration process with a system designed to...

Reverse osmosis system for wine production

Enhance wine quality and versatility with advanced reverse osmosis systems that...

Grape sorting and washing lines

Optimize grape processing with efficient sorting and washing lines that streamline the prepa...

Grape stem extractor for winemaking

Efficiently remove grape stems to enhance quality in winemaking and streamline your pro...

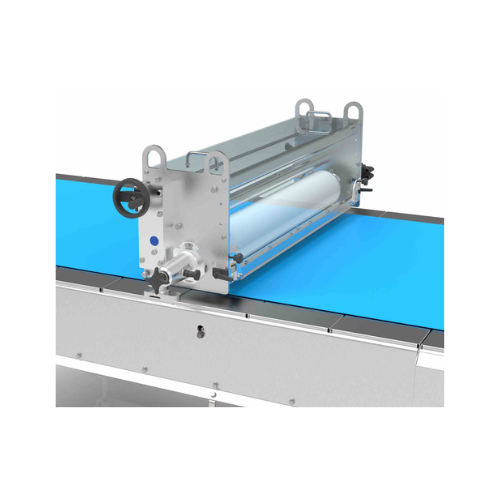

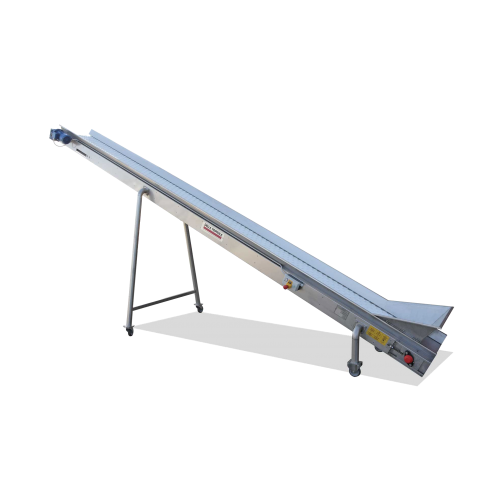

Conveyor belts for grape processing

Streamline your grape processing with stainless steel conveyor belts, engineered for ef...

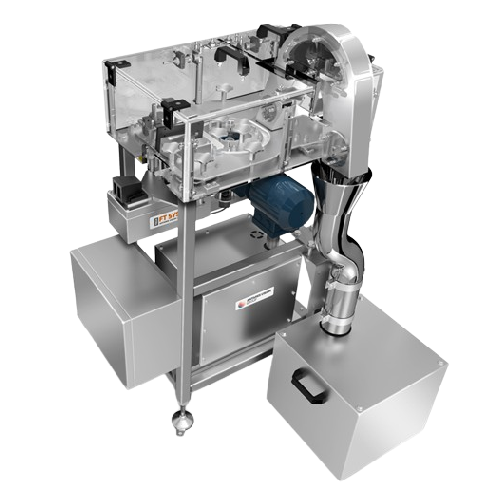

Crusher destemmer for grapes

Achieve consistent grape processing with precise separation and minimal crushing, preserving th...

Tanks with screw conveyors for grape reception

Optimize grape reception with customizable tanks equipped with screw convey...

Scraped-surface wine coolers for efficient cooling

Ensure optimal temperature control for winemaking with advanced coolin...

Isobaric filling solution for carbonated drinks

Achieve precision filling for carbonated and still beverages with advanced...

Wine clarification flotator

Achieve superior wine clarity efficiently by integrating a single-tank flotation solution that s...

Continuous wine flotation unit for must clarification

Enhance your must clarification process with a continuous flotation...

Continuous flotation units for wine clarification

Optimize your wine and juice production with our advanced flotation uni...

Continuous sugar dissolving system for beverage production

Effortlessly transform granulated sugar into a consistent, hi...

Press-on capping system for bottles

Ensure precise and secure closure of various bottle types with our versatile press-on c...

Cross flow filtration for beer production

Optimize your beer filtration process and minimize product loss with advanced cr...

Sheet filters for wine and beer filtration

Enhance your filtration process with reliable sheet filters designed for high-q...

Low temperature freeze dryer for high sugar or acid content products

Perfect for producing freeze-dried goods from food...

Saturation unit for carbonating beverages

Elevate your beverage production with continuous carbonation, ensuring precise g...

Cip systems for beverage filling plants

Ensure optimal cleanliness and hygiene in your beverage production line with advanc...

Cleaning solution tanks for beverage production

Achieve superior internal cleaning of beverage containers with our advance...

Heating and cooling tunnel for beverages

Achieve consistent temperature regulation for beverages, ensuring optimal product ...

Self-adhesive labelling system for bottles

Enhance your bottling line with a versatile labelling system that supports medi...

Compact wet glue labeling system for low volume production

Achieve precise, high-quality labeling with compact machinery...

High-speed wet glue labelling system

Ensure precise labelling on diverse bottle types with our versatile rotary labelling s...

Compact combined labelling solution for bottling lines

Optimize your bottling line with a versatile, compact labelling so...

Combined wet glue and self-adhesive labeling system

Achieve seamless labeling with combined wet glue and self-adhesive te...

Self-adhesive labeling system for bottles

Streamline your bottling operations with high-precision labeling that enhances p...

Semi-automatic filler for bag-in-box packaging

Streamline your liquid packaging process with a versatile filler that integ...

Bag-in-box carton erector

Experience seamless carton erection with advanced servomotor technology, enhancing both efficiency...

Automatic palletiser for bag-in-box packaging line

Streamline your packaging process with a cartesian palletiser designed...

200l buffer tank for bag-in-box fillers

Ensure precise filling and consistent flow control with this stainless steel buffer...

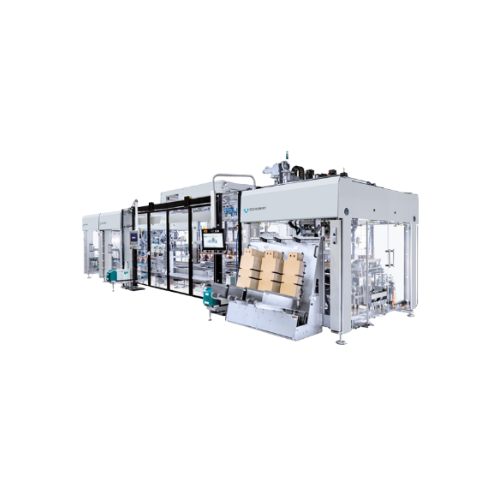

Bag-in-box fully automatic filling line

Streamline your liquid packaging operations with a modular system designed to enhan...

Buffer tank for bag-in-box filling

Optimize your liquid packaging with precise flow control and pressurization, ensuring st...

Wine filtration system for microbiological purity

Ensure your wines achieve the highest clarity and microbiological purit...

Manual bag-in-box filling solution

Streamline your liquid packaging with a compact, easy-to-operate filling system that sim...

Manual pneumatic filler for bag-in-box

Experience seamless filling for liquid formulations with this pneumatic solution, en...

Manual filling system for bag-in-box packaging

Streamline your liquid filling process with a manual system designed for pr...

Bag-in-box filler with dual heads and automatic features

Boost your liquid production efficiency with a dual-head filling...

Rotary continuous motion bottle cleaning solution

Ensure pristine product integrity by effectively eliminating particles ...

Industrial cooling unit for beverages and spirits

Ensure optimal chilling and condensation for beverages and spirits with...

Storage tanks for wine preservation

Ensure optimal preservation of beverages with robust storage solutions featuring precis...

Automatic cross-flow filter for wine

Experience enhanced filtration efficiency with reduced waste, as this cross-flow filte...

Discontinuous flotation unit for wine must clarification

Achieve rapid and effective clarification of wine musts using co...

Cross-flow lees filter for wine and juice lees

Optimize your beverage filtration process by ensuring high-quality output a...

Advanced must, juice, and wine turbocooler

Optimize your beverage production with precise temperature control, ensuring co...

Continuous distillation columns for spirits production

Optimize your spirits production with advanced distillation column...

Thermostabilizer for beer and wine sterilization

Ensure biological stability in beverages by efficiently inactivating yeas...

Desulphurisation of mute must

Ensure your wine’s purity by efficiently removing sulfur dioxide, safeguarding its chemi...

Plate filter for beverage sterilization

Achieve absolute clarity and sterilization of your beverages with a versatile plate...

Vacuum concentrator for juice and chemical processing

Reduce energy and concentration costs significantly while enhancing...

Helicoid heat exchanger for grape mash and fruit pulp

Enhance your beverage processing with a heat exchanger designed for...

Pre-coat filter with horizontal discs for wine

Ensure optimal clarity in your beverage processes with a solution designed ...

Rotary vacuum filter for wine filtration

Enhance your wine production with efficient filtration of grape must and wine lees...

Self-cleaning pre-coat filter for wine filtration

Solve complex filtration challenges effectively with this advanced self...

Continuous tartar stabilization for small wine batches

Achieve continuous tartar stabilization in wine with precise cryst...

Heat pump vacuum concentrator for must concentration

Achieve delicate must concentration with minimal energy consumption,...

Cross-flow filtration unit for clarifying juice and wine

Achieve optimal clarity and yield with this semicontinuous cross...

Versatile steam distillation unit for laboratory applications

Achieve reliable analysis of complex samples with this ste...

Cross-flow filtration for wine and fruit juice

Achieve high-quality filtration and purification for liquid and slurry prod...

Wine storage and fermentation tanks

Designed for optimal wine fermentation and storage, these tanks offer precise temperatu...

Industrial homogenizer for food and beverage applications

For manufacturers seeking consistent quality, this homogenizer...

No-oxygen wine filler

Ensure product integrity with advanced no-oxygen filling systems, designed to preserve delicate flavors...

No-oxygen filler for wine bottling

Enhance liquid bottling with seamless integration that minimizes oxygen exposure, ensuri...

High-capacity no-oxygen wine filler

Ensure optimal flavor retention and prevent oxidation in your bottling process with adv...

Industrial capping systems for bottling lines

Optimize your bottling process with versatile capping solutions designed for...

Inspection system for filled glass bottles

Ensure high-quality beverage bottling by detecting bottle faults, contaminants,...

Industrial bottle rinsing systems

Ensure pristine bottle hygiene and maintain high production standards with advanced rinsi...

Automatic packaging line for bag-in-box

Streamline your bag-in-box production with a seamless solution that ensures precisi...

Automatic case erector for cartonboard packaging

Streamline your packaging process with precision engineering that simplif...

Automatic case erector for cartonboard packaging

Streamline your packaging process and enhance operational efficiency with...

Automated quality control for beverage packaging

Streamline beverage quality control with 24/7 automated analysis, ensurin...

Co2/o2 beverage filling device

Ensure precise beverage analysis by maintaining carbonation integrity with a system that tran...

Packaged beverage analyzer for alcohol and Co2

Ensure precise beverage analysis with a streamlined solution that integrate...

Packaged beverage analyzer for beer, wine, and cider

Ensure precision in beverage quality control with rapid, direct samp...

Depalletising solutions for bottles and containers

Optimize your production line with advanced depalletising solutions th...

Automatic case erector for american cases

Streamline your packaging line with high-speed case erecting, reducing labor cos...

Full label inspection system for not-oriented containers

Ensure precise label application and integrity on any container ...

Gas analyzer for beverage bottle vacuum level

Ensure precise vacuum level measurement in bottle headspace with non-destruc...

Pressure monitoring system for classic method wine production

Ensure your sparkling wine’s quality with precise in...

Cap inspection and fill level inspection system for beverage containers

Ensure precise cap application and fill level m...

Cap quality inspection system for beverage industry

Ensure flawless cap performance and prevent production disruptions wi...

Empty bottle inspection system for beverage industry

Enhance your production line’s efficiency by detecting defects...

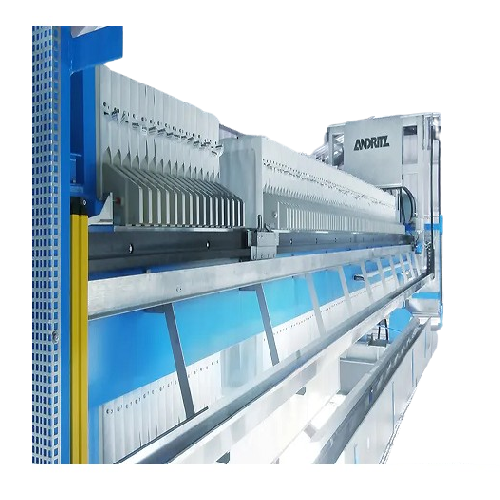

Industrial filter press for dewatering and filtration

Optimize your dewatering and filtration needs with a highly adaptab...

Decanter centrifuge for food industry separation

Achieve precise separation and ensure optimum product quality with our ad...

Plate type pasteurizer for juice and tea drinks

Ensure optimal heating, sterilization, and cooling for juice and tea produ...

Small bottle linear type beverage filling production line

Optimize your bottling efficiency with a high-speed solution d...

Automatic bottle cold glue labeling solution

Achieve precise labeling for diverse container types, enhancing your producti...

Centrifuge separator for food and beverage clarification

Ensure high efficiency and minimal product loss in your producti...

Bag-in-box filling solution for non-aseptic products

Maximize your production line’s efficiency with a high-speed f...

Foodec decanter centrifuge for food processing

Achieve high yields and clear liquid separation in your food processing lin...

Double-wall scraped surface heat exchanger

Achieve high-capacity processing with gentle handling for shear-sensitive produ...

Scraped surface heat exchanger for viscous products

Efficiently handle challenging viscosities and heat-sensitive product...

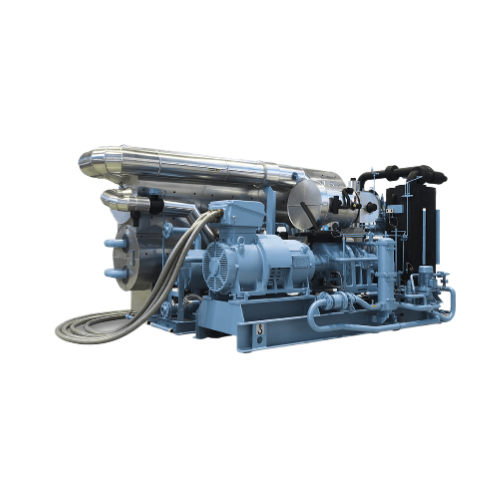

Reverse osmosis concentration system for beer and beverages

Optimize transport and storage of beverages by reducing volu...

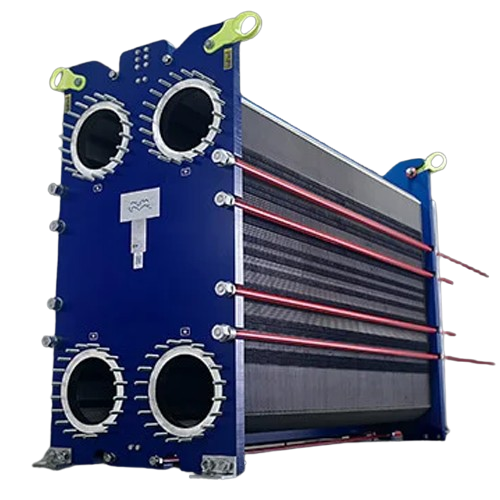

Gasketed plate heat exchangers for hygienic applications

Ensure optimal hygiene and thermal efficiency in your processing...

High pressure gasketed plate heat exchangers for carbonated beverages

When ensuring high-pressure handling in your past...

Scraped surface heat exchanger for high-pressure applications

Handle high-viscosity and particulate-rich products with p...

Double seat valve for hygienic processing

Eliminate cross-contamination risks and enhance efficiency with a modular valve ...

Gasketed plate-and-frame heat exchangers for industrial applications

Optimize your production with precise thermal mana...

Vacuum breaker valve for Htst pasteurization systems

Prevent vacuum conditions in high-temperature pasteurization systems...

Automatic volumetric filler for liquid products

Optimize your production with this high-precision volumetric filler, desig...

Steam shrink tunnels for versatile packaging

Enhance your packaging efficiency with this adaptable steam shrink tunnel, de...

Rotary bottle rinser for high-speed production lines

Ensure thorough cleaning and preparation of containers with a high-s...

Inspection-rejection station for bottled products

Ensure your bottled and packaged products ship defect-free by automatic...

Centrifugal pump for high-pressure systems

Designed for high-pressure systems, this centrifugal pump ensures precise filtr...

Customized industrial heat pumps

Optimize your industrial processes with versatile heat pumps that recover and utilize waste...

Air conveyor for empty Pet bottles

Optimize your bottling line with an advanced air conveyor that reduces energy consumptio...

Reverse osmosis dealcoholization technology

Elevate your beverage production capabilities with advanced dealcoholization t...

Centrifuge for beverage clarification

Elevate your beverage production with enhanced clarification, ensuring your drinks me...

Reverse osmosis dealcoholization technology for beer

Achieve consistent flavor profiles in your non-alcoholic beer produc...

Reverse osmosis beer dealcoholization technology

Achieve precise alcohol removal from beer while preserving flavor integri...

Industrial chiller with high part-load efficiency

Optimize your cooling processes with a versatile chiller designed for p...

Wine decanting and clarification system

Streamline your wine production with a multi-functional decanting system designed t...

Glass bottle washing and delabelling system

Effortlessly transform used bottles into pristine, reusable containers with th...

Cold-glue labeller for cylindrical or shaped containers

Achieve seamless high-speed labeling of glass, plastic, and metal...

Modular and combined labeling machines for bottling

Achieve high-speed labeling with unmatched flexibility, combining mul...

Ultraclean filling monoblocks for food industry

Enhance product safety and quality with monoblocks designed for ultraclean...

Hot fill bottling unit for juices and isotonic beverages

Ideal for producers handling delicate or specialty liquids, this...

Level bottle filler for wine and spirits

Achieve consistent fill levels with precision sensor technology, ideal for ensurin...

Volumetric bottle filler for distilled spirits

Ensure precise volume control and compliance with regulatory standards in y...

Volumetric bottle filler for high proof spirits

Ensure precise and consistent bottle filling for high-proof spirits with t...

Counter pressure filler for carbonated beverages

Ensure optimal carbonation and minimal oxygen exposure during bottling, e...

Counter pressure can filler for carbonated beverages

Achieve precise carbonation levels and minimal oxygen exposure in ca...

Counter pressure bottle filler for carbonated beverages

Maintain carbonation levels while filling bottles efficiently, en...

Counter pressure bottle filling system for carbonated beverages

Enhance your bottling efficiency with a versatile counte...

Cip system for bottling line sanitation

Ensure optimal hygiene in your bottling operation with efficient CIP systems that i...

Frontal filtration system for wine clarification

Ensure your wine retains its unique flavors and aromas with an energy-eff...

Microfiltration systems for wine pre-bottling

Ensure product stability in pre-bottling by efficiently removing particles t...

Low profile slide valve for controlling powder flow

Optimize your powder and granule flow management with precision-engin...

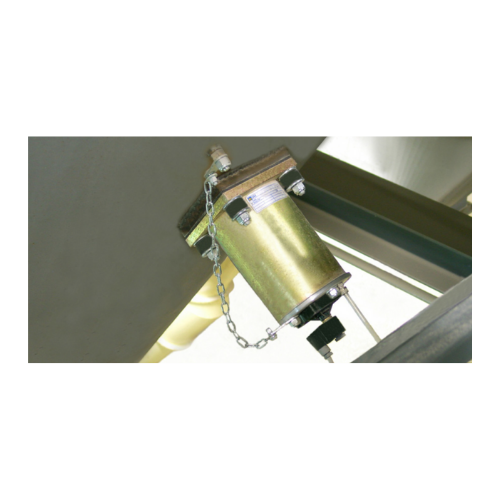

Pneumatic hammers for bulk solids discharging

Optimize your production efficiency and solve material flow challenges with ...

Continuous impact vibrators for bulk material removal

Combat material flow issues like bridging and rat-holing with our i...

External electric motovibrators for bulk solids conveying

Enhance material flow efficiency and solve challenging dischar...

Cushioned pneumatic vibrators for coarse particle materials compaction

Enhance your material flow and compaction proces...

Stainless steel trough screw conveyor

Ideal for precise handling of powdery and granular materials, this solution ensures m...

Horizontal stand-up pouching for beverages, dairy, and pet care

Optimize your liquid product packaging with rapid, high-...

Stand-up pouch packaging for various industries

Elevate your packaging capabilities with a high-speed horizontal pouching ...

Continuous stand-up pouching solution for up to 1000ml

Maximize efficiency in high-speed production lines with precise st...

Horizontal stand-up pouching system for liquids and solids

For producers aiming to optimize efficiency and precision, th...

Centrifugal separators for liquid/liquid/solid separation

Achieve efficient separation and clarification for diverse app...

Autonomous ingredient dissolver for high-volume dry ingredient mixing

Efficiently mix multiple high volumes of dry ingr...

Vacuum bottling equipment for wineries and breweries

Optimize your bottling process with a vacuum solution that fills up ...

Vacuum filler for wine and oils

Optimize your beverage bottling process with a compact vacuum filler designed for precise le...

Jacketed kettle for porridge and sauce cooking

Efficiently heat and mix diverse liquid and slurry products with precise te...

Industrial decanter centrifuge for solids separation

Optimize your production line with high-speed decanter centrifuges t...

Direct drive centrifuges for dairy and beverage processing

Optimize energy efficiency in high-speed liquid separation wi...

Hyper-clean electronic volumetric filler for Pet bottles

Enhance your liquid filling operations with precision and hygien...

Integrated stretch-blow moulding, filling, and capping system for still liquids

Streamline your bottling process with ...

Optical sorting for vinification grapes

Enhance grape quality with precise optical sorting, effectively eliminating under-r...

Rotating fermenters for wine making

Enhance your wine production with advanced fermenters designed for rapid extraction of ...

Tank washers for barrel and vat cleaning

Effortlessly maintain hygiene and efficiency in your production line with tank was...

Vibrating table for grape selection

Effortlessly enhance the quality of your grape processing with precision sorting, ensur...

Horizontal fermentation tanks for winemaking

Achieve optimal fermentation with minimal liquid lees through advanced cap ma...

Vertical fermentation tanks for winemaking

Achieve optimal fermentation with vertical tanks designed for gentle must movem...

Integrated linear blowing and filling system for Pet containers

Streamline your PET container production with integrated...

Cryogenic pre-treatment system for grapes

Prevent premature fermentation and enhance extraction in wine production with a ...

Industrial box washer for wineries

Efficiently tackle the challenge of residue build-up in your processing containers with ...

De-juicing unit for wine must processing

Optimize your winemaking process by effectively separating seeds and skins from wi...

Industrial grape destemmer and crusher

Optimize your wine production with precise destemming and crushing, ensuring top qua...

Cold pre-fermentation system for wine extraction

Enhance your wine’s flavor profile with rapid extraction of color, ...

Pneumatic fuller for grape marc cap immersion

Achieve optimal grape marc cap immersion with pneumatic precision, ensuring ...

Gravity filling system for Pet bottles

Optimize your beverage production with an advanced gravity filling system, designed ...

Cip sanitizing unit for food and beverage production

Ensure meticulous hygiene with a compact unit designed for seamless ...

Cartoning solutions for beverage and food industries

Optimize your packaging line with a versatile range of cartoning sys...

Large size container linear blow molder

Optimize your large-scale production of containers with a solution designed to stre...

Heat exchangers for wine processing

Ensure precise temperature control and efficient cooling for your wine-making process w...

Punching down trolley for wine fermentation

Enhance the extraction of flavors and aromas in your wine fermentation process...

Compartmented tank for wine processing

Optimize your wine production with precise temperature control and efficient space u...

Cylindrical insulated tanks for wine production

Optimize fermentation and storage stages with precision temperature contro...

White and rosé wine-making Se elliptical tank

Optimize your wine production with an elliptical tank designed for perfect a...

Parallelepipedic tank for wine processing

Streamline your wine-making processes with a versatile tank designed for both re...

Truncated wine fermentation tank

Achieve optimal temperature control and efficient maceration for red wine production with a...

Wine storage tanks for temperature monitoring and control

Optimize your wine-making process with advanced tanks, designe...

Heat recovery boiler for milk cooling systems

Capture the wasted thermal energy from milk cooling and transform it into us...

Instant milk cooling systems for dairy farms

Optimize your dairy operations by instantly cooling milk with systems designe...

Remote monitoring app for milk coolers

Ensure milk quality and streamline operations with a remote monitoring app that prov...

Tank cleaning system for milk quality assurance

Ensure immaculate milk quality and operational efficiency with an automate...

Aseptic tank for liquid food storage

Store and maintain the sterility of low and high acid liquid foods while ensuring prod...

Continuous sugar dissolver for high brix solutions

Optimize your beverage production with a system that dissolves sugar u...

Pasteurization solution for food liquids

Extend the shelf-life of your liquid products while maintaining their quality with...

Custom syrup preparation systems

Optimize your beverage production with precision-engineered syrup preparation systems desig...

Uht sterilization solution for liquid food products

Enhance your liquid food processing with reliable UHT sterilization, ...

Industrial solutions for beverage mixing and carbonation

Optimize your beverage production with precise mixing and carbon...

Multifunction case packer for bottles and jars

New ways of packaging products are popping up all the time on the market. T...

Wrap-around case packer for cans or bottles

When it comes to beer packaging, most of the manufacturers use plain box carto...

Wraparound case packer

Packaging companies need to pay attention to personalization in shape and design in addition to the at...

Self-adhesive linear labeling machine for bottles

It is vital to have precise and long-lasting labels on bottles to avoid...

Cartoner with partitions for wine

Products filled in glass containers like wine, usually require carton packaging with pref...

Industrial crate washing machine

In order to meet the increasing demand of the beverage industry, it’s essential to find a c...

Industrial bottle washing machine

Polyethylene terephthalate (PET) and glass bottles are widely used in the beverage indust...

Industrial bottle sterilizer

Sterilization is an important process in the beverage industry to kill microorganisms. It is im...

Air knife system for bottling lines

Wet containers are unacceptable and can be problematic in the food and beverage industr...

CIP system for beverage

Clean-in-place operations are a mandatory part of food and beverage processing which cannot fail. How...

Tunnel pasteurizer for beverage

In the beverage industry, beverages need to be pasteurized in order to destroy pathogens, an...

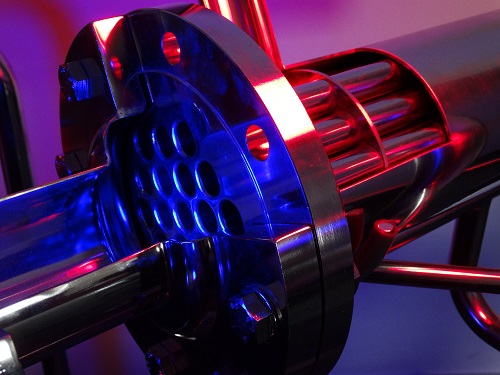

Shell and tube heat exchanger

Heating, cooling and tempering are important processes in the production of many products acro...

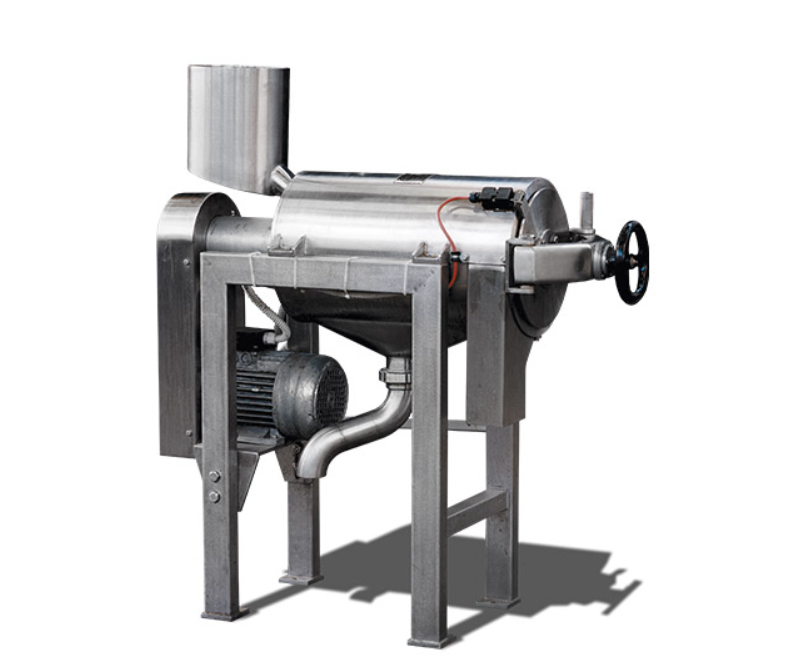

Fruit pulping machine

When making fruit pulp, a pulping machine helps you remove seeds, stems, and skins from your fruit. How...

Versatile bottle sorting system

Quality bottle sorting machine and inspection system which can be put to use not only after ...

High-speed unscrambler for large bottles

Large volume plastic bottling plants need high-speed unscramblers suitable for lar...

High-speed unscrambler for small bottles

Large-scale production of smaller volume bottled product needs a gentle, accurate ...

Low-speed unscrambler

Smaller plastic bottling lines need a lower cost, lower volume unscrambling machine that maintains gent...

Full crate inspection system

State of the art crate inspection system that uses a laser camera system to see if the bottles ...

High-precision X-ray fill level controller

High-speed, high precision X-ray system to inspect containers that are difficul...

High-frequency fill level controller

In terms of high-frequency technology, the fill level detection is considered a standa...

Advanced residual liquid inspection system

Advanced and easy to use inspection system that eliminates the risk of residual...

Residual liquid inspection system

Inspection system that eliminates the risk of residual liquid, water or left over drink i...

Empty bottle height sorting system

An empty bottle sorting system that uses the light barrier technology. It detects bottle...

Empty crate inspection system

Extensive and much-differentiated inspection of both the crate and the bottle that allows you ...