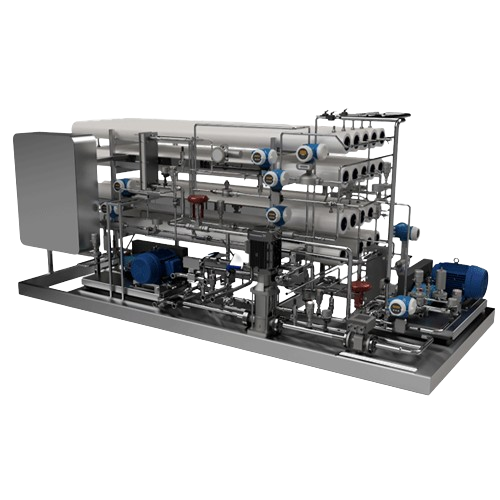

Reverse osmosis concentration system for beer and beverages

Optimize transport and storage of beverages by reducing volume with advanced reverse osmosis technology, achieving concentrated products with retained taste, aroma, and alcohol content for seamless rehydration at serving points.

Concentrates Alcoholic Beverages via Reverse Osmosis

The Alfa Laval Revos™ concentration system is a cutting-edge solution for breweries, wineries, and beverage manufacturers seeking efficient concentration of alcoholic beverages. This advanced system utilizes a high-pressure, low-temperature reverse osmosis process to effectively remove water while retaining up to 22% alcohol by volume. The two-pass design ensures that aromas, proteins, and minerals remain intact in the concentrate, preserving the original sensory qualities when rehydrated. Ideal for applications in beer, wine, and cider production, the Revos system reduces shipping volumes by up to 80%, cutting transportation costs and optimizing distribution logistics.

With the ability to integrate seamlessly into existing production lines, the Revos system is designed for continuous, high-pressure operation, maintaining product integrity through a chilled membrane filtration process. Energy-efficient and economical, it offers significant savings in transportation costs by allowing rehydration at final destinations such as bars or restaurants. Its compact design saves valuable floor space, making it an excellent choice for establishments looking to maximize efficiency and minimize waste. Alfa Laval also offers pilot testing and rentals to ensure that the system meets specific operational requirements, with engineering support available for tailored solutions.

Benefits

- Reduces shipping costs by up to 80% through concentrated product transport.

- Preserves original taste and aroma, ensuring consistent product quality upon rehydration.

- Saves valuable space at point-of-sale locations with on-demand rehydration.

- Enhances beverage stability, supporting extended shelf life.

- Lowers carbon footprint through energy-efficient reverse osmosis technology.

- Applications

- Cider, Beer, Alcoholic beverages, Wine

- End products

- Concentrated cider, Cider concentrate, Concentrated wine, Concentrated beer, Beer concentrate, Wine concentrate

- Steps before

- Fermentation, Chilling

- Steps after

- Rehydration, Packaging, Distribution

- Input ingredients

- beer, wine, cider, water, proteins, sugars, aromas, minerals

- Output ingredients

- beer concentrate, wine concentrate, cider concentrate, water permeate, up to 22% alcohol by volume, retained proteins, retained sugars, retained aromas, retained minerals

- Market info

- Alfa Laval is renowned for its expertise in heat transfer, separation, and fluid handling technologies, providing innovative, energy-efficient engineered-to-order solutions for various industries including food, marine, and energy.

- Alcohol by volume (ABV)

- Up to 22%

- Transport cost reduction

- Up to 80%

- Reverse osmosis type

- High-pressure, low-temperature

- Membrane type

- Proprietary spiral-wound

- Concentration passes

- Two-pass

- Pore structure

- Tight

- Beverages processed

- Beer, wine, cider

- Operating temperature

- Low-temperature

- Working mechanism

- High-pressure, low-temperature reverse osmosis

- Integrated steps

- Two-pass processing

- CIP/SIP

- Available

- Batch vs. continuous operation

- Continuous

- Automation level

- Automated

- Cleaning method

- Low-temperature patented process

- Energy efficiency

- Economical and energy-efficient

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Compact footprint

- Yes

- Discharge method

- Proprietary spiral-wound membranes

- Machine Dimensions

- Not Specified

- Machine Weight

- Not Specified

- Rehydration capability

- On-site at point of sale