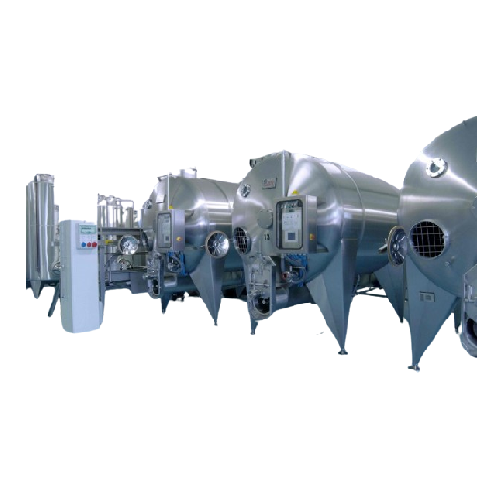

Horizontal fermentation tanks for winemaking

Achieve optimal fermentation with minimal liquid lees through advanced cap management and precise temperature control, ensuring premium wine quality.

Facilitates Efficient Wine Fermentation and Grape Marc Handling

The Horizontal Fermentation Tanks from Sirio Aliberti S.r.l. are engineered to optimize winemaking processes by minimizing liquid lees and ensuring product quality. These tanks incorporate an inverter-controlled motor that adjusts the speed of rotating paddles for gentle cap punching down and efficient must displacement. Ideal for producing red, white, rosé, sparkling, and fortified wines, they seamlessly integrate into processing and final conditioning operations within wineries. The tanks offer variable-speed automation for precise control over fermentation conditions, employing a temperature conditioning pocket for optimal thermal management. They also feature automated unloading of grape marc, with an optional screw conveyor for mid-process extraction. Constructed for durability and efficiency, these tanks cater to wineries seeking streamlined operations and enhanced wine quality through customized configurations tailored to specific production needs.

Benefits

- Enhances wine quality by minimizing liquid lees through precise must displacement.

- Optimizes fermentation control, reducing energy costs via variable-speed motor technology.

- Streamlines operations with automated grape marc unloading, saving time and labor.

- Customizable configurations cater to specific winery requirements, enhancing process flexibility.

- Facilitates efficient temperature management, ensuring ideal conditions for diverse wine types.

- Applications

- Winemaking, Beverage processing, Wine production, Fermentation processes

- End products

- Rosé wine, Red wine, Fortified wine, White wine, Sparkling wine

- Steps before

- Crushing, Juice Extraction, Must Clarification

- Steps after

- Filtration, Aging, Bottling

- Input ingredients

- must, grape marc

- Output ingredients

- liquid lees, exhausted grape marc

- Market info

- Sirio Aliberti (Omnia Technologies) specializes in manufacturing industrial engineered-to-order (ETO) equipment, known for their customized solutions, innovative engineering, and high-quality standards, catering to various industry sectors with a strong focus on customer requirements and precision engineering.

- Liquid Lees Reduction

- Minimal

- Paddle Rotation Speed

- Variable

- Temperature Control

- Optimal fermentation process

- Marc Unloading

- Automatic

- Marc Extraction During Vinification

- Screw conveyor version available

- Automation

- Motor with inverter

- Working mechanism

- Gentle displacement with paddles

- Punching down process

- Variable speed paddles

- Temperature control

- Temperature conditioning pocket

- Exhausted grape marc unloading

- Automatic unloading paddles

- Grape marc extraction

- Screw conveyor

- Customization

- Made-to-measure versions

- Abrasion resistance

- Yes

- Biological compatibility

- Food-grade materials

- Cleanability

- Easy to clean surfaces

- Corrosive resistance (e.g. acids)

- Stainless steel construction

- Tank shape

- Horizontal

- Size

- Customizable

- Tank feature

- Integrated paddles

- Discharge method

- Automatic unloading / Screw conveyor

- Temperature control

- Temperature conditioning pocket

- Motor control

- Inverter-equipped

- Paddle speed

- Variable

- Temperature control

- Integrated temperature pocket

- Marc unloading option

- Automatic / Screw conveyor

- Custom size

- Made to measure