Automated case erector for high-speed packaging lines

Streamline your packaging line with this solution that forms and secures cartons with precision, ensuring your products are ready for efficient, high-speed packing and shipping.

Streamlines Bottle and Carton Packaging Process

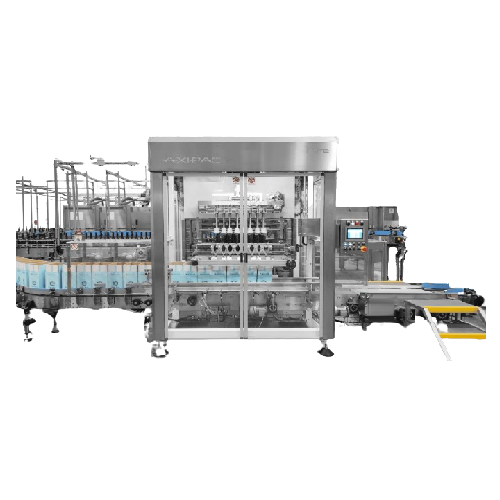

The Flexi Series from APE Impianti is a high-capacity packaging solution designed for seamless integration into your production line. Featuring Axipack technology, it modularly adapts to diverse production spaces and requirements. This series excels in bottling and carton applications within wine, beer, spirits, and food industries by efficiently conducting carton forming, case erecting, bottle picking, partition inserting, and case sealing operations. With automation capabilities that offer continuous operation at up to 12,000 bottles per hour, the Flexi Series ensures both speed and flexibility. It uses brushless motors for precise movement control, optimizing speed variations during cycles, and reduces energy consumption compared to conventional systems. Modular configuration options, including a Crate Kit for returnable glass bottles, highlight its adaptability. Maintenance is streamlined with automated format changes accessible via a user-friendly operator panel, ensuring minimal downtime and optimizing productivity.

Benefits

- Increases packaging line efficiency with integrated processes, reducing manual handling.

- Adapts to varying production requirements with modular design, optimizing available space.

- Enhances precision and consistency in packaging cycles with brushless motor control.

- Minimizes energy usage and operational costs with streamlined power management.

- Simplifies maintenance and reduces downtime through quick, automated format changes.

- Applications

- Food, Beverage packaging, Wine, Spirits, Beer

- End products

- Beer bottles, Returnable glass bottles, Wine bottles, Spirit bottles, Food packaging, Beverage cartons

- Steps before

- Bottle preparation, Bottle washing

- Steps after

- Carton sealing, Palletizing

- Input ingredients

- bottles, cartons, plastic crates, glass return bottles, RSC - AMERICAN carton

- Output ingredients

- packed bottles, sealed cartons, processed plastic crates, assembled RSC - AMERICAN cartons

- Market info

- Speed

- Up to 12, 000 bottles/hour

- Automation

- Brushless motors for maximum control

- Handling System

- Radial handling system controlled by an inverter

- Carton Type

- RSC - AMERICAN carton

- Glue Type

- Hot-melt glue for closing flaps

- Control System

- Single operator panel

- Packaging Cycle

- Maximum control in every cycle

- Flexibility

- Modular design

- Automation level

- PLC-controlled

- Batch vs. continuous operation

- Inline Continuous

- Changeover time

- Automated format changes

- Integrated solution

- Case erector to cartoner integration

- Modularity

- Fully modular

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Container type

- RSC - AMERICAN carton, Plastic crates

- Container size

- 750ml, 500ml, 330ml, 250ml bottles

- Filling purpose

- Packaging, Case Packing

- Packaging method

- Automatic case erector, packer, and inserter

- Sealing method

- Hot-melt glue

- Handling materials

- Glass, Cartonboard

- Output rate

- Up to 12, 000 bottles/hour

- Changeover capability

- Fast, automated format changes

- Machine footprint

- Compact

- Control panel type

- Single operator panel

- Discharge method

- Hot-melt glue closure

- Footprint adaptability

- Modular to space

- Flexibility

- Highly modular

- Control panel type

- Operator panel

- Integration possibilities

- AXIPACK modular technology

- Automation level

- Brushless motors

- Modular configuration

- Yes, fully modular

- Space requirements

- Compact solution without connecting belts