Depalletisers for high-capacity bottle handling

Streamline your bottling line with a versatile depalletising system designed to efficiently handle varying workloads and container types, enhancing productivity and reducing manual labor.

Transfers Empty Bottles to Production Line

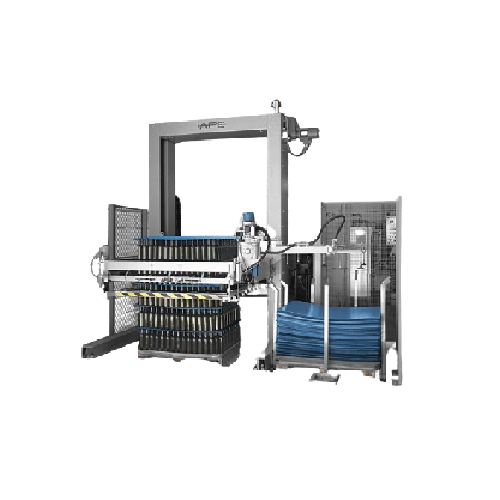

The BABYDEPAL from APE IMPIANTI is a neck-handling depalletiser designed to enhance production efficiency for beverage and food industries. It facilitates the effortless transfer of empty bottles and containers directly to the bottling line with a simple but effective inflatable tube mechanism. The equipment is available in automatic and semi-automatic versions, supporting operations tailored to your facility’s needs. Capable of handling up to 8,000 bottles per hour, BABYDEPAL caters to small to mid-sized production lines aiming to reduce manual intervention and physical strain on operators. Its compact design suits facilities with limited space, while customization options allow integration with existing systems, enabling higher levels of automation. This depalletiser proves indispensable for wineries, breweries, and food processors seeking reliable and efficient depalletizing solutions.

Benefits

- Enhances productivity by enabling rapid transfer of bottle layers with minimal physical effort.

- Adapts to existing production lines, optimizing space with its compact design.

- Increases operational flexibility with customizable automation levels.

- Minimizes labor costs and risk of injury through automated operation.

- Supports diverse production needs with configurations for various bottle sizes and types.

- Applications

- Food, Wine, Containers, Spirits, Bottles, Beer

- End products

- Beer bottles, Plastic bottles, Wine bottles, Empty spirits bottles, Beverage bottles, Liquid containers, Empty beer bottles, Food containers, Empty wine bottles, Spirits bottles, Glass bottles

- Steps before

- Bottle Production, Bottle Sorting, Label Removal

- Steps after

- Bottling, Filling, Labeling, Packaging

- Input ingredients

- empty bottles, containers, large pallet, interlayer

- Output ingredients

- depalletised bottles, depalletised containers

- Market info

- Automation

- Automatic / Semi-automatic

- Speed

- 3, 000 to 25, 000 bottles/hour

- Capacity

- Up to 25, 000 bottles/hour

- Handling Type

- Neck-handling

- Customization Options

- Customizable layout

- Footprint

- Compact

- Machine Type

- Layer depalletiser

- Configuration

- Adjustable via software

- Container Compatibility

- Multi-format

- Pallet Size

- Large pallet 1420x1120 mm

- Automation Level

- Automatic / Semi-automatic

- Footprint

- Compact

- Capacity

- 3, 000 to 25, 000 bottles/hour

- Flexibility

- High

- Cycle Speed

- Up to layer transfer in less than a minute

- Handling Method

- Neck-handling with inflatable tubes

- Space Requirement

- Very small spaces

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Compact

- Container handling capability

- Neck-handling

- Pallet size compatibility

- Large pallet 1420x1120 mm

- Version options

- Automatic / Semi-automatic

- Footprint efficiency

- Reduced footprint

- Machine Version

- Automatic / Semi-automatic / Large Pallet

- Footprint

- Compact design

- System Customizability

- Customer layout requirements

- Automation Level

- Manual / Fully automatic

- Container Handling

- Neck-handling / Multi-format