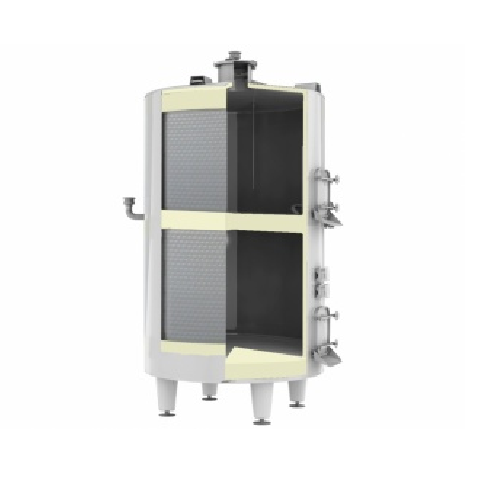

Compartmented tank for wine processing

Optimize your wine production with precise temperature control and efficient space utilization, ensuring perfect fermentation and maturation for both red and white wines.

Controls Fermentation, Storage, and Temperature Stabilization

The Compartmented Wine Fermentation and Storage Tank from The SERAP Group offers innovative solutions for wineries and beverage manufacturers. This stainless steel tank, available in AISI 304, AISI 316L, or combined metal standards, optimizes the fermentation and stabilization processes through precise temperature control. Its design includes a multi-compartment layout with top compartments featuring floating lids for effective wine storage, allowing for plot-by-plot relocations. The tank supports fermentation and storage of both red and white wines, with an optional agitator for enhanced mixing.

The tank can be tailored with options such as an isothermal wall for energy efficiency, using SERAP’s proprietary insulation technique involving polyurethane foam injection. This reduces condensation and minimizes energy consumption, crucial for maintaining ideal conditions during wine processing. The unit integrates smoothly into existing winery operations, featuring laser-welded surfaces for efficient heat exchange and temperature control.

Constructed with durability in mind, the tank supports high stress and service gangways through its sandwich structure, facilitating operational safety. Cleaning is streamlined with minimal water and chemical usage, while the optional isothermal feature further supports sustainability initiatives. Ideal for batch and continuous operations, the tank aligns with various production needs in the wine, food, and beverage industries.

Benefits

- Ensures optimal wine quality through precise temperature and stabilization control.

- Minimizes energy usage and condensation with optional isothermal design.

- Enhances operational flexibility with multi-compartment configuration for plot-by-plot relocations.

- Lowers cleaning costs with efficient water and chemical use.

- Supports sustainable production practices with reduced energy consumption and efficient material use.

- Applications

- Beverage processing, Wine

- End products

- White wine, Red wine

- Steps before

- Grape Harvesting, Sorting, Crushing, Fermentation Preparation

- Steps after

- Wine Aging, Filtration, Bottling, Labeling

- Input ingredients

- grapes, must, red wine materials, white wine materials

- Output ingredients

- red wine, white wine, stabilized wine, processed wine

- Market info

- Material Type

- AISI 304, AISI 316L, 1.4301/1.4404

- Interior Finish

- Cold rolled or bright annealed

- Wall Type

- Plain or isothermal

- Insulation Method

- Polyurethane foam injection

- Cooling Method

- Laser-welded exchange surfaces

- Agitator Option

- Optional agitator in compartments

- Storage Temperature Control

- Controlled temperatures and atmospheres

- Tartaric Stabilisation

- Optional

- Structural Design

- Tank with legs, skirts or radiated

- Space Saving

- Volume stacking

- Batch vs. continuous operation

- Batch / Inline Continuous

- Automation level

- Manual / PLC / SCADA

- CIP/SIP

- CIP 121°C / SIP 135°C

- Cleaning method

- CIP / Manual

- Energy efficiency

- Optimized with laser-welded exchange surfaces

- Temperature control

- Optimum with small volume of coolant fluid

- Insulation method

- Polyurethane foam injection

- Space saving

- Volume stacking

- Tartaric stabilization

- Optional

- Wine Type Compatibility

- Red / White

- FDA materials

- AISI 304, AISI 316L or combined stainless steel

- Tank shape

- Cylindrical, compartmented

- Material type

- AISI 304, AISI 316L stainless steel

- Tank finish

- Cold rolled or bright annealed interior

- Insulation method

- Polyurethane foam injection

- Footprint type

- Tank with legs, skirts, or radiated

- Volume control

- Laser-welded exchange surfaces

- Lid type

- Floating lid on the top compartment

- Isothermal option

- Available

- Material Type

- AISI 304, AISI 316L or combined stainless steel

- Wall Type

- Plain or isothermal

- Insulation Type

- Polyurethane foam injection

- Interior Finish

- Cold rolled or bright annealed

- Structural Support

- With legs, skirts or radiated

- Top Compartment

- Floating lid fitted

- Agitator Option

- Optional in two compartments

- Temperature Control

- Optimum temperature control with laser-welded exchange surfaces