Automated packaging line for bottling industry

Streamline your packaging operations with a fully automated solution designed to transition from manual processes, enhancing efficiency and consistency in handling bottling tasks across multiple products.

Automates Case Erecting, Packing, Partition Inserting, and Sealing

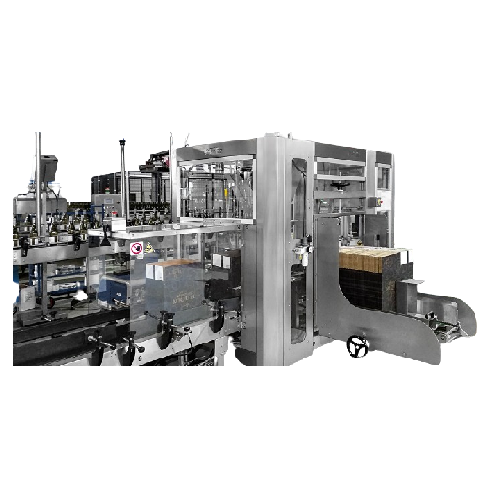

The Series 1300 from APE IMPIANTI is a comprehensive solution for automating the packaging processes in the wine, beer, spirits, and food industries. This suite of equipment, including the FORM 1300 for automatic case erecting, INCA 1300 for precise case packing, INSER 1300 for effortless partition inserting, and CH 1300 for secure case sealing, collectively enhances operational efficiency and reduces manual intervention.

Engineered for high-speed and continuous operations, the Series 1300 supports producers in achieving throughput rates of up to 6,000 bottles per hour. Each unit is designed to integrate seamlessly into existing production lines, with advanced automation and control features enabling smooth synchronization with upstream and downstream processes. The equipment is particularly suitable for bottling operations, tackling the typical packaging challenges of handling volumes of 250ml to 750ml wine, beer, and spirits bottles, as well as various food packaging cartons.

Built with a robust mechanical structure and innovative software, the Series 1300 ensures reliability and user-friendliness. The hot-melt applicators in the FORM and CH models enhance packaging integrity, making this series a compelling choice for those seeking durability and ease of use. Designed with flexibility in mind, the Series 1300 accommodates a wide range of American (RSC) cases, and its customizable features allow it to meet specific production needs. Dedicated engineering support from APE IMPIANTI is readily available to tailor the Series 1300 to fit unique operational requirements.

Benefits

- Increases efficiency by automating manual packaging tasks, leading to significant labor cost reductions.

- Enhances production speed and consistency, handling up to 6,000 bottles per hour without manual oversight.

- Secures packaging integrity with precise case sealing and hot-melt application, minimizing product damage during transit.

- Offers flexible integration with existing lines, accommodating a diverse range of case sizes and bottle volumes.

- Simplifies operation and maintenance with user-friendly interfaces and robust mechanical design, reducing downtime.

- Applications

- Food, Beer, Spirits, Wine

- End products

- Wine bottles, Spirits bottles, Food packaging cartons, Beer bottles

- Steps before

- Bottle preparation, Bottle inspection

- Steps after

- Case sealing, Palletization, Logistics handling

- Input ingredients

- RSC American cases, flat cardboard partitions, bottles, hot-melt adhesive

- Output ingredients

- sealed American cases, packed bottles, partitioned cases, up to 6, 000 bottles/hr

- Market info

- Speed

- Up to 6, 000 bottles/hr

- Automation

- Automatic

- Case Types

- American cases (RSC)

- Sealing Method

- Hot-melt applicator

- Motion Control

- Advanced in "PLUS" version

- Mechanical Structure

- Strong

- Software

- Latest generation

- Insertion

- Automatic for flat cardboard partitions

- Automation level

- Fully automatic

- Changeover time

- Minimal

- Batch vs. continuous operation

- Batch

- Cleaning method

- Manual / Semi-automatic

- Energy efficiency

- Optimized for low energy consumption

- Corrosive resistance

- Yes

- Cleanability

- High

- Abrasion resistance

- Yes

- Density/particle size

- Varies based on material

- Container size,shape

- 750ml, 500ml, 330ml, 250ml

- Carton capacity

- 6, 12, 20, 24

- Case style

- RSC (Regular Slotted Container)

- Control panel type

- Latest generation software

- Discharge method

- Automatic case packer

- Partition inserter type

- Flat cardboard with vibrating belt option

- Case sealing method

- Hot-melt applicator

- Control panel type

- PLC-based HMI

- Integration possibilities

- Modular design for flexibility

- Motion control

- Advanced motion control in PLUS version

- Partition inserter option

- Vibrating belt available